Diffusion welding method for super-multilayer hydrogen peroxide catalytic layer net

A hydrogen peroxide and diffusion welding technology, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems that the brazing technology needs to be further optimized, achieve good permeability, ensure stability, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Furnace welding:

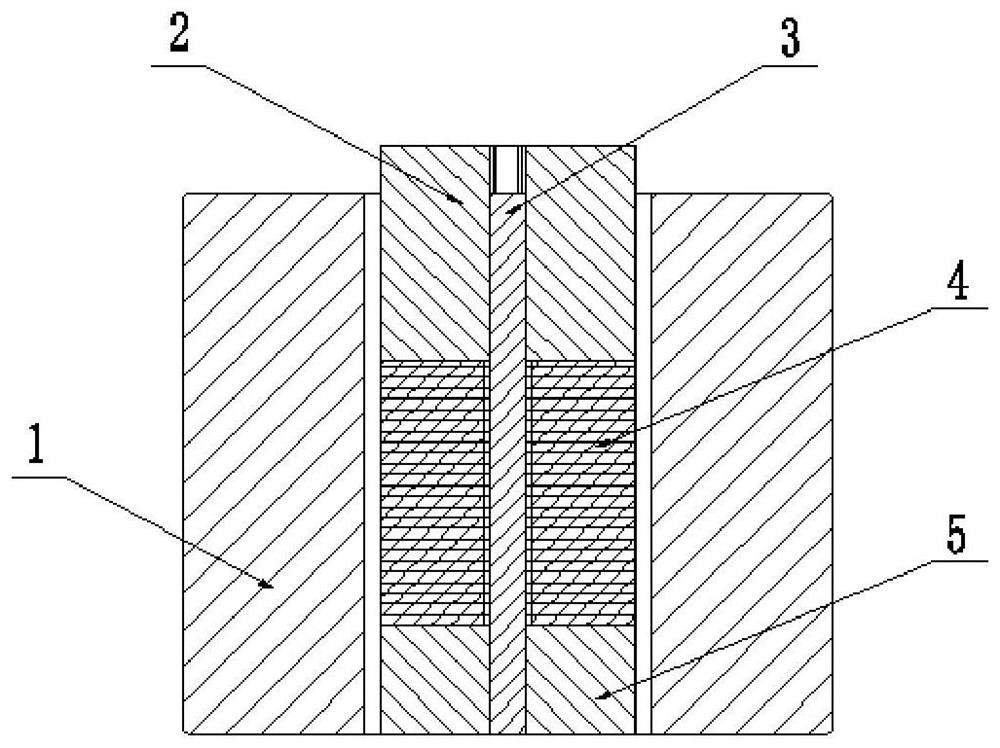

[0047] Put the assembly components into the vacuum furnace, and pump the vacuum furnace to 2×10-3pa and keep the vacuum degree until the heating process is completed.

[0048] The vacuum furnace indenter applies a downward pressure of 700kg on the upper end face of the upper indenter 2, gradually heats up to 660°C at a heating rate of 2°C / min, adjusts the pressure to 500kg pressure, and keeps the temperature for 15min. The diffusion welding process ends.

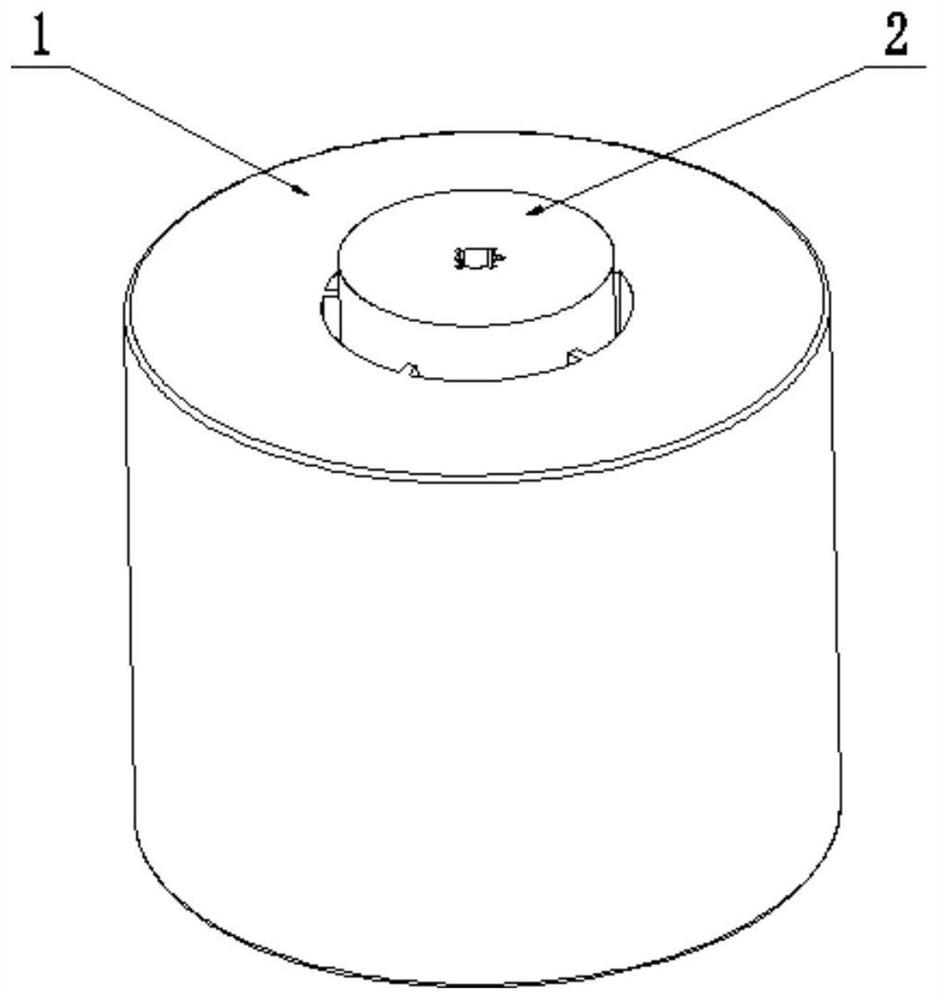

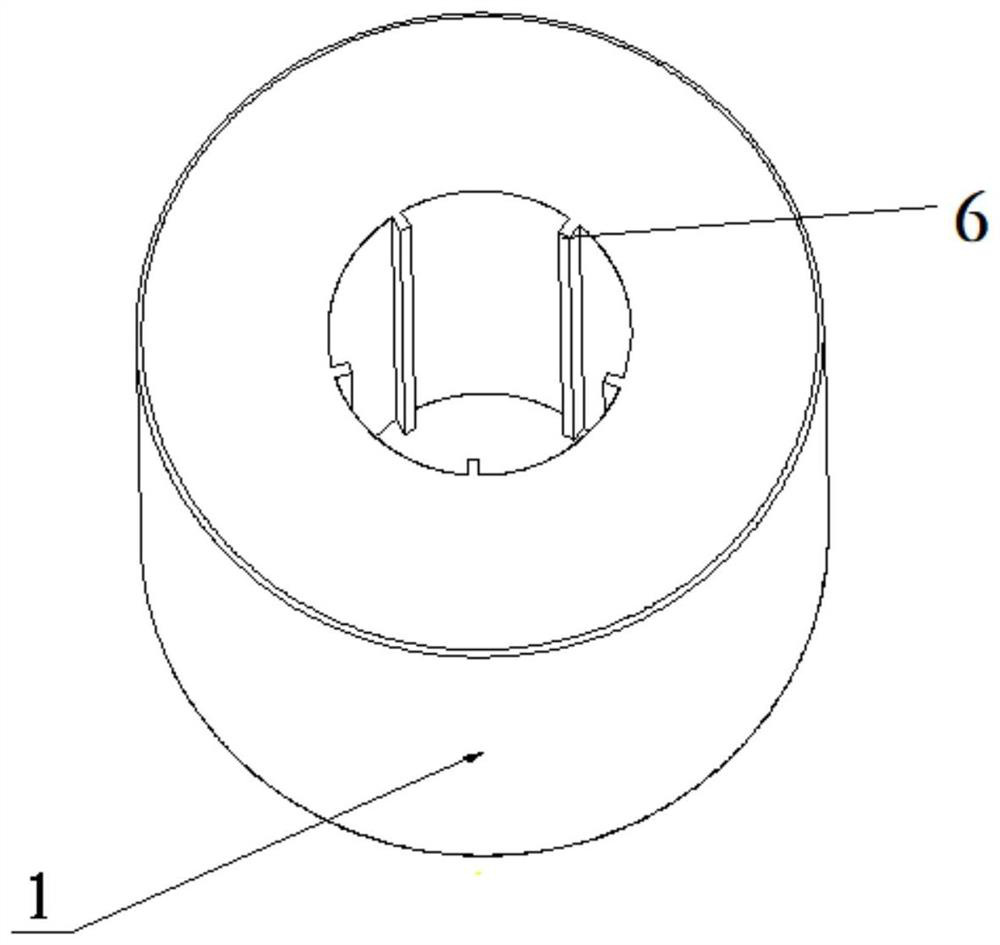

[0049] Cool down and cool down and take out the parts: when the temperature in the vacuum furnace reaches 50 ℃, open the cover and take out the parts. Remove the tooling of the outer sleeve 1, the upper indenter 2, the lower indenter 5, and the mandrel 3 in turn according to the reverse assembly sequence, and finally obtain an ultra-multi-layer hydrogen peroxide catalytic layer mesh diffusion welding assembly.

Embodiment 2

[0051] Furnace welding:

[0052] Put the assembly components into the vacuum furnace, and pump the vacuum furnace to 3×10-3pa to keep the vacuum degree until the heating process is completed.

[0053] The vacuum furnace indenter exerts a downward pressure of 750kg on the upper end face of the upper indenter 2, gradually increases the temperature to 680°C at a heating rate of 3°C / min, adjusts the pressure to 550kg pressure, and keeps the temperature for 20min. The diffusion welding process ends.

[0054] Cool down and cool down and take out the parts: when the temperature in the vacuum furnace reaches 75 ℃, open the cover and take out the parts. Remove the tooling of the outer sleeve 1, the upper indenter 2, the lower indenter 5, and the mandrel 3 in turn according to the reverse assembly sequence, and finally obtain an ultra-multi-layer hydrogen peroxide catalytic layer mesh diffusion welding assembly.

Embodiment 3

[0056] Furnace welding:

[0057] Put the assembled components into the vacuum furnace, and pump the vacuum furnace to 4×10-3pa and keep the vacuum degree until the heating process is completed.

[0058] The vacuum furnace indenter exerts a downward pressure of 800kg on the upper end face of the upper indenter 2, gradually increases the temperature to 700℃ at a heating rate of 5℃ / min, adjusts the pressure to 600kg pressure, and maintains the temperature for 25min. The diffusion welding process ends.

[0059] Cool down and cool down and take out the parts: when the temperature in the vacuum furnace reaches 100 ℃, open the cover and take out the parts. Remove the tooling of the outer sleeve 1, the upper indenter 2, the lower indenter 5, and the mandrel 3 in turn according to the reverse assembly sequence, and finally obtain an ultra-multi-layer hydrogen peroxide catalytic layer mesh diffusion welding assembly.

[0060] The diffusion welding method of the ultra-multi-layer hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com