Full-automatic bottle blowing method for large-capacity PP bottles

A large-capacity, fully automatic technology, applied in the field of bottle blowing machines, can solve the problems of being unable to adapt to the continuous feeding speed, continuous flipping and feeding, difficulty in controlling the uniform heating inside and outside the preform, and high requirements for the preform heating process to achieve continuous Preheating operation, docking transfer is smooth and efficient, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

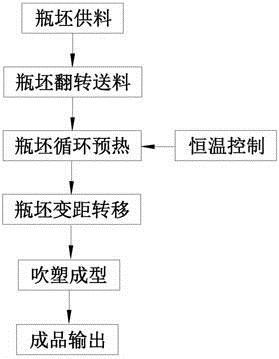

[0065] Large-capacity PP bottle automatic blowing method, such as figure 1 shown, including the following steps:

[0066] Step 1, preform feeding: the preforms 60 are arranged by the preform supply module 10 and are fed one by one with the bottle mouth up;

[0067] Step 2, preform overturning and feeding: the preform 60 output by the preform supply module 10 is clamped on the preform turning mechanism 1 in an orderly manner and rotates with the preform turning mechanism 1 to an inverted state with the bottle mouth facing down. is guided and transferred to the blank feeding mechanism 2; and

[0068] Step 3: Preheating of the preform cycle: The preform 60 in the inverted state is transferred from the preform feeding mechanism 2 to the constant temperature preheating module 30 for a multi-stage preheating treatment of alternating heating and cooling cycles.

[0069] Preferably, in the above step 2, the preform 60 is clamped in the preform clamping position 12 on the rotary pref...

Embodiment 2

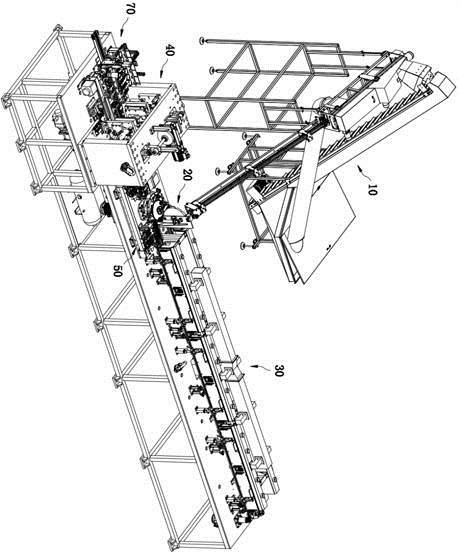

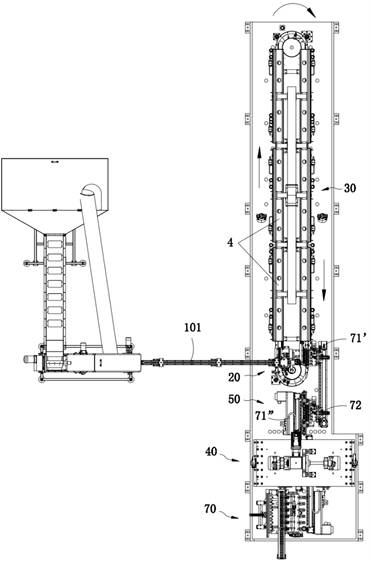

[0083] This embodiment provides a large-capacity PP bottle automatic blowing production line, such as Figure 2-3As shown, it includes: a blank supply module 10, and also includes: a reverse blank feeding module 20 connected to the output end of the blank supply module 10, and a constant temperature preheating module connected to the output end of the reverse blank delivery module 20. 30, a bottle blowing module 40, and a variable-distance transfer module 50 connected and arranged between the constant temperature preheating module 30 and the bottle blowing module 40; further comprising: a finished product transfer module 70, the finished product transfer module 70 is located in the blowing One side of the bottle module 40 relative to the constant temperature preheating module 30; such as Figure 4 As shown, the inverting blank feeding module 20 includes: a blank turning mechanism 1 arranged to rotate vertically, and a blank feeding mechanism 2 arranged to rotate horizontally a...

Embodiment 3

[0102] The same or corresponding components in this embodiment and the above-mentioned embodiments are marked with corresponding reference numerals as in the above-mentioned embodiments. For the sake of simplicity, only the points of difference from the above-mentioned embodiments will be described below. The difference between this embodiment and the above-mentioned embodiment is:

[0103] Preferably, as Figure 4-5 As shown, the constant temperature preheating module 30 includes: a rotary transmission mechanism 3, the inversion preform feeding module 20 is located above the rotary transmission mechanism 3, and the preforms 60 are outputted by the inversion preform feeding module 20. On the rotary transmission mechanism 3, such as Image 6 As shown, several groups of directional preheating units 4 are distributed along the transmission path of the rotary transmission mechanism 3 and are covered thereon, and an open-structured cooling space is provided between the adjacent tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com