Immersed membrane biological integrated reactor for up-to-standard reinjection of oilfield produced water into ultra-low permeable layer and application of immersed membrane biological integrated reactor

An immersed membrane and produced water technology, which is applied in mining wastewater treatment, aerobic and anaerobic process treatment, etc., can solve the problems of substandard treated water quality and low degradation efficiency of organic matter, and can prolong the chemical cleaning cycle and operation time. Simple structure, prolonging the effect of chemical cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

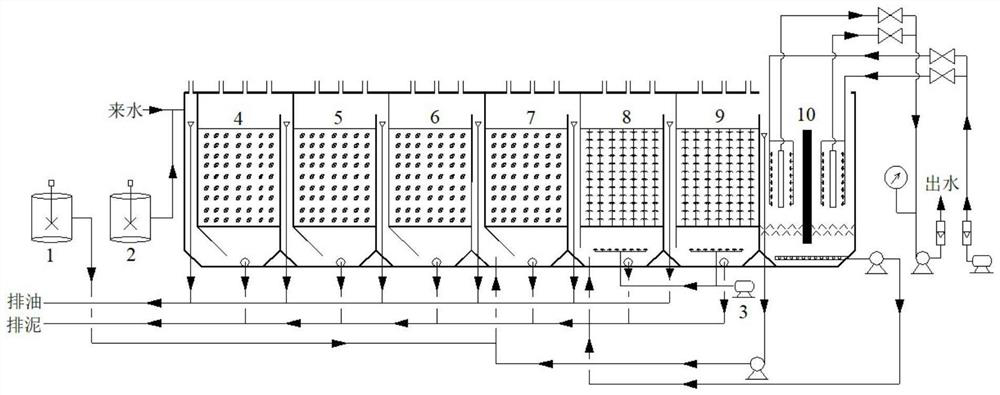

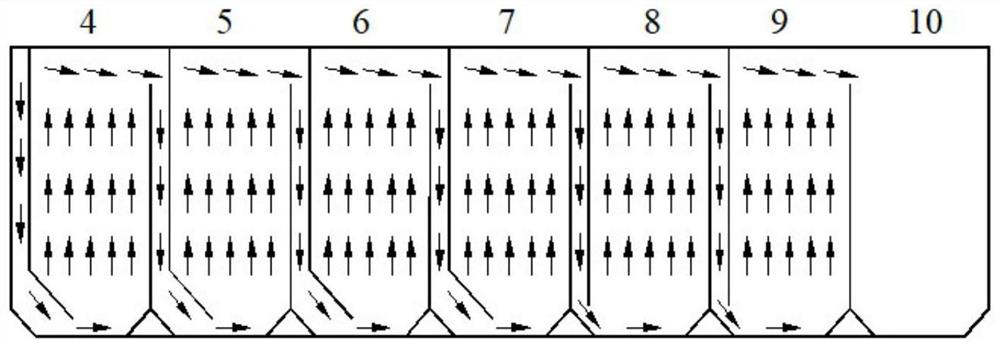

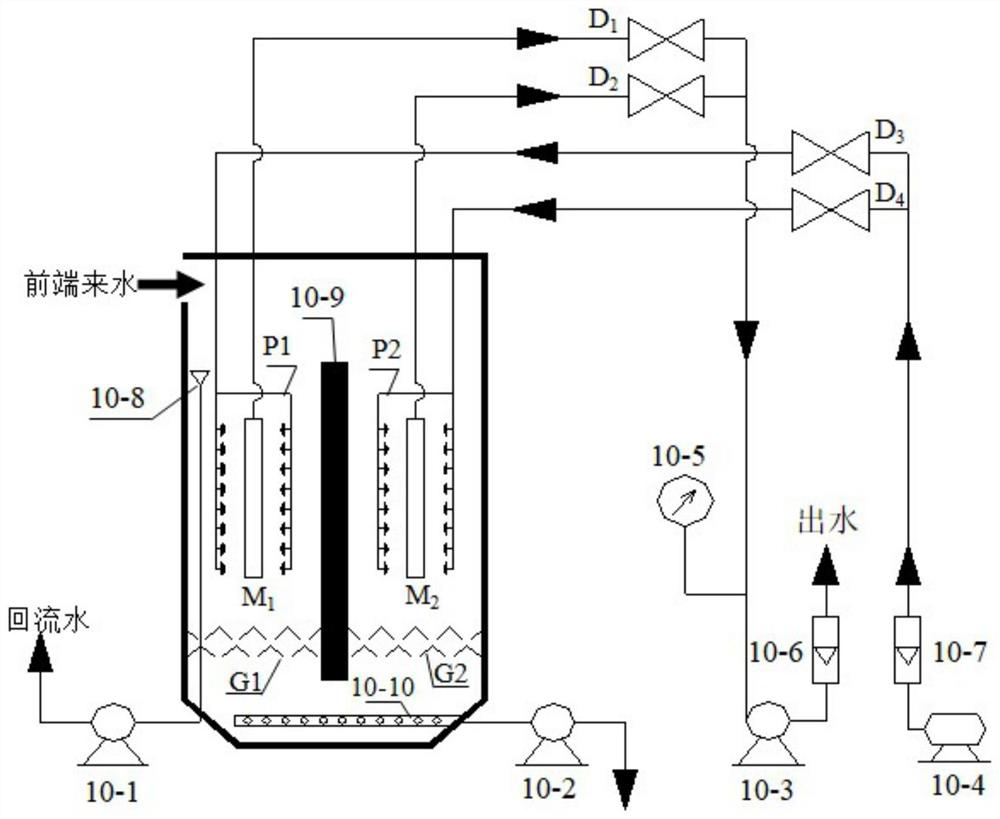

[0027] Embodiment 1: In this embodiment, a submerged membrane bio-integrated reactor used for oilfield produced water to meet the standard and reinjection into an ultra-low permeability layer, includes a box body, and the inside of the box body is divided into multiple parts by baffles along the water flow direction The reaction chamber, the multiple reaction chambers are the first anaerobic chamber 4, the second anaerobic chamber 5, the third anaerobic chamber 6, the anoxic chamber 7, the first aerobic chamber 8, and the second aerobic chamber 9. , a water inlet is provided on the upper part of the side of the box close to the first anaerobic chamber 4, the anoxic chamber 7 and the bottom of the first aerobic chamber 8 are provided with a return port, and the first aerobic chamber 8 and the second aerobic chamber are provided with a return port. The bottom of 9 is provided with an air inlet; the bottom of all reaction chambers is provided with a mud phase outlet connected with...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that: the first solid-liquid separation system G1 and the second solid-liquid separation system G2 have the same structure; the first solid-liquid separation system G1 and the second solid-liquid separation system G1 The structure of the liquid separation system G2 is composed of two layers of angle steel that are staggered up and down evenly. There are gaps between the two adjacent angle steels, and the gap flow rate is less than or equal to 2m / h; °, and both ends are connected to the inner wall of the submerged membrane reaction chamber 10 . Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the second fan 3 arranged outside the box is connected to the aeration pipes at the bottom of the first aerobic chamber 8 and the second aerobic chamber 9 Pass. Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com