High-strength anti-crack recycled concrete and preparation method thereof

A technology of recycled concrete and waste concrete blocks, which is applied in the field of recycled concrete, can solve the problems of reducing the service life and durability of recycled concrete, low bonding fastness of cement mortar, and easy cracking, etc., and achieves inhibition of alkali-aggregate reaction, excellent Crack resistance and service life, the effect of guaranteeing crack resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

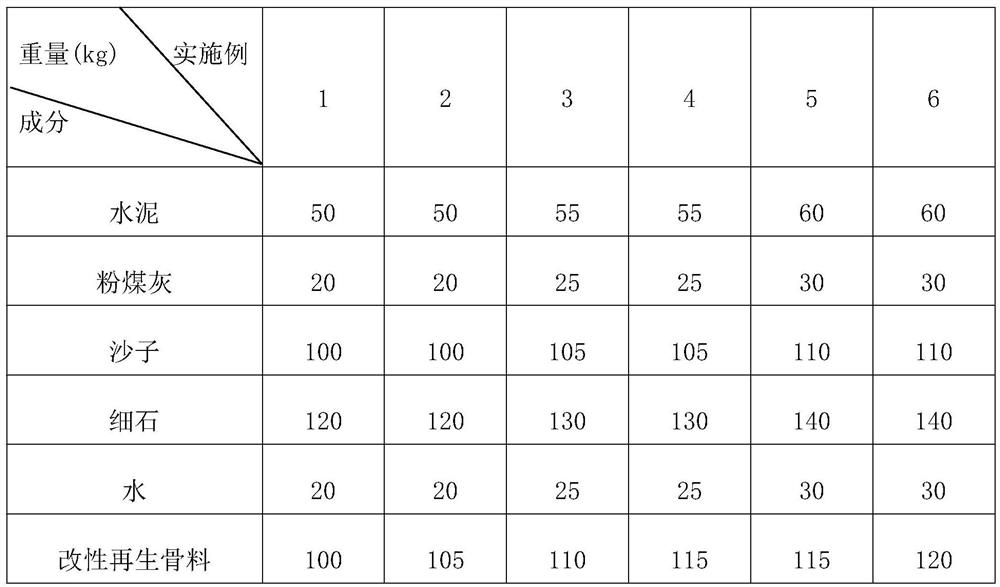

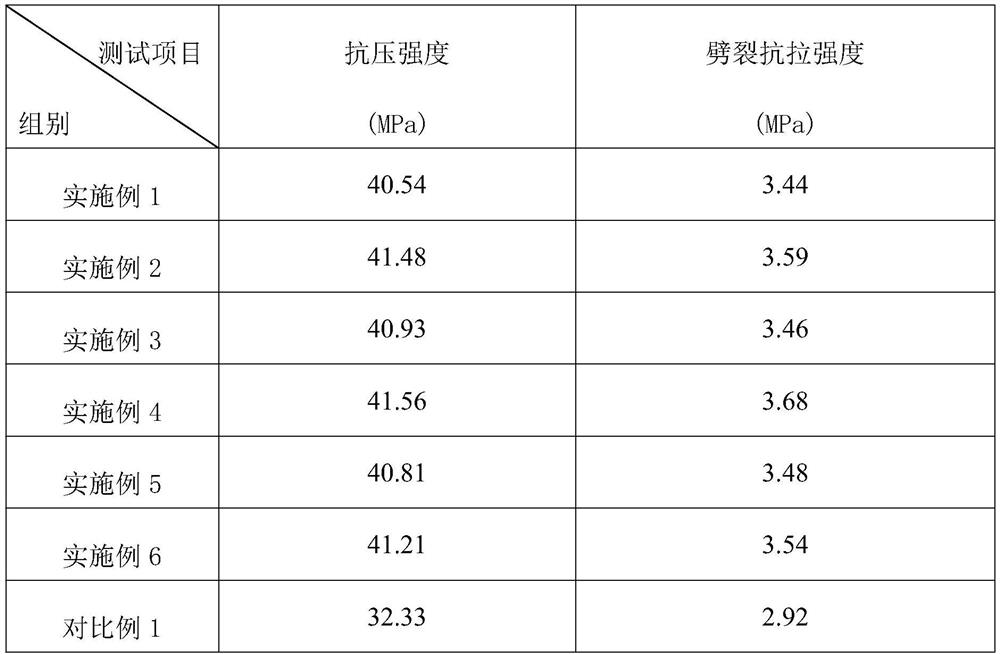

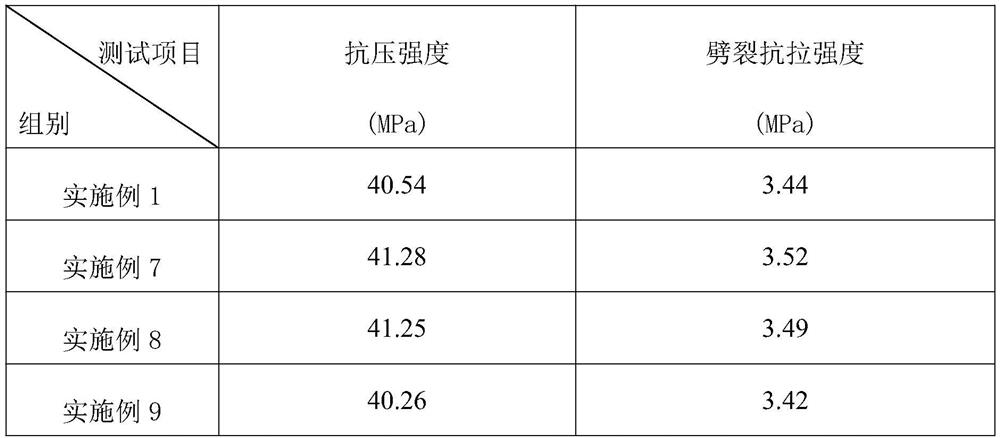

Examples

preparation example 1

[0060] A modified regenerated aggregate is prepared and obtained by adopting the following steps:

[0061] a. First, the waste concrete blocks and the porous modified powder are mixed and calcined at a weight ratio of 1:0.1 at 1000 °C for 6 hours, then soaked in an oxalic acid aqueous solution with a pH of 4.5 for 30 minutes, cooled to room temperature, crushed and ground, and the particle size is less than 30mm. The crushed powder is for standby use, and in this application, it is a continuous stage crushed powder of 10-25mm;

[0062] The porous modified powder is diatomaceous earth;

[0063] b. Put the crushed powder obtained in a into the modified liquid at a weight ratio of 1:0.8, mix for 1 hour, and then dry at 600°C to obtain modified regenerated aggregate for use;

[0064] The modified liquid is composed of water and silica sol in a weight ratio of 1:0.2.

preparation example 2

[0066] A modified regenerated aggregate is prepared and obtained by adopting the following steps:

[0067] a. First, the waste concrete blocks and the porous modified powder were mixed and calcined at 1200 °C for 4 hours at a weight ratio of 1:0.1, and then soaked in an oxalic acid aqueous solution with a pH of 4.5 for 30 minutes, cooled to room temperature, and crushed and ground to obtain a particle size smaller than 30mm. of crushed powder for use;

[0068] The porous modified powder is diatomaceous earth;

[0069] b. Put the crushed powder obtained in a into the modified liquid at a weight ratio of 1:0.8, mix for 1 hour, and then dry at 600°C to obtain modified regenerated aggregate for use;

[0070] The modified liquid is composed of water and silica sol in a weight ratio of 1:0.2.

preparation example 3

[0072] A modified regenerated aggregate is prepared and obtained by adopting the following steps:

[0073] a. First, the waste concrete blocks and the porous modified powder are mixed and calcined at a weight ratio of 1:0.1 at 1500 ° C for 2 hours, then soaked in an oxalic acid aqueous solution with a pH of 2.5 for 10 minutes, cooled to room temperature, and crushed and ground to obtain a particle size of less than 30mm. of crushed powder for use;

[0074] The porous modified powder is diatomaceous earth;

[0075] b. Put the crushed powder prepared in a into the modified liquid at a weight ratio of 1:0.8, mix for 3 hours, and then dry at 800°C to obtain modified regenerated aggregate for use;

[0076] The modified liquid is composed of water and silica sol in a weight ratio of 1:0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com