A kind of SIC continuous fiber containing al/cu double coating and its preparation method and application

A continuous fiber, double-coating technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., to achieve good uniformity, avoid severe interface reaction, and improve the effect of interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

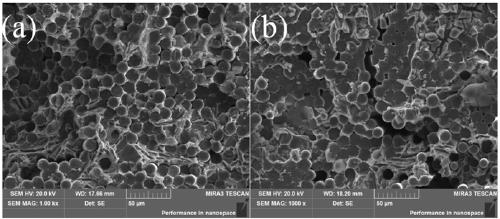

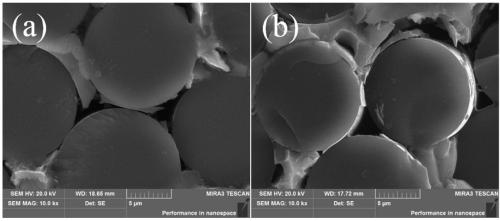

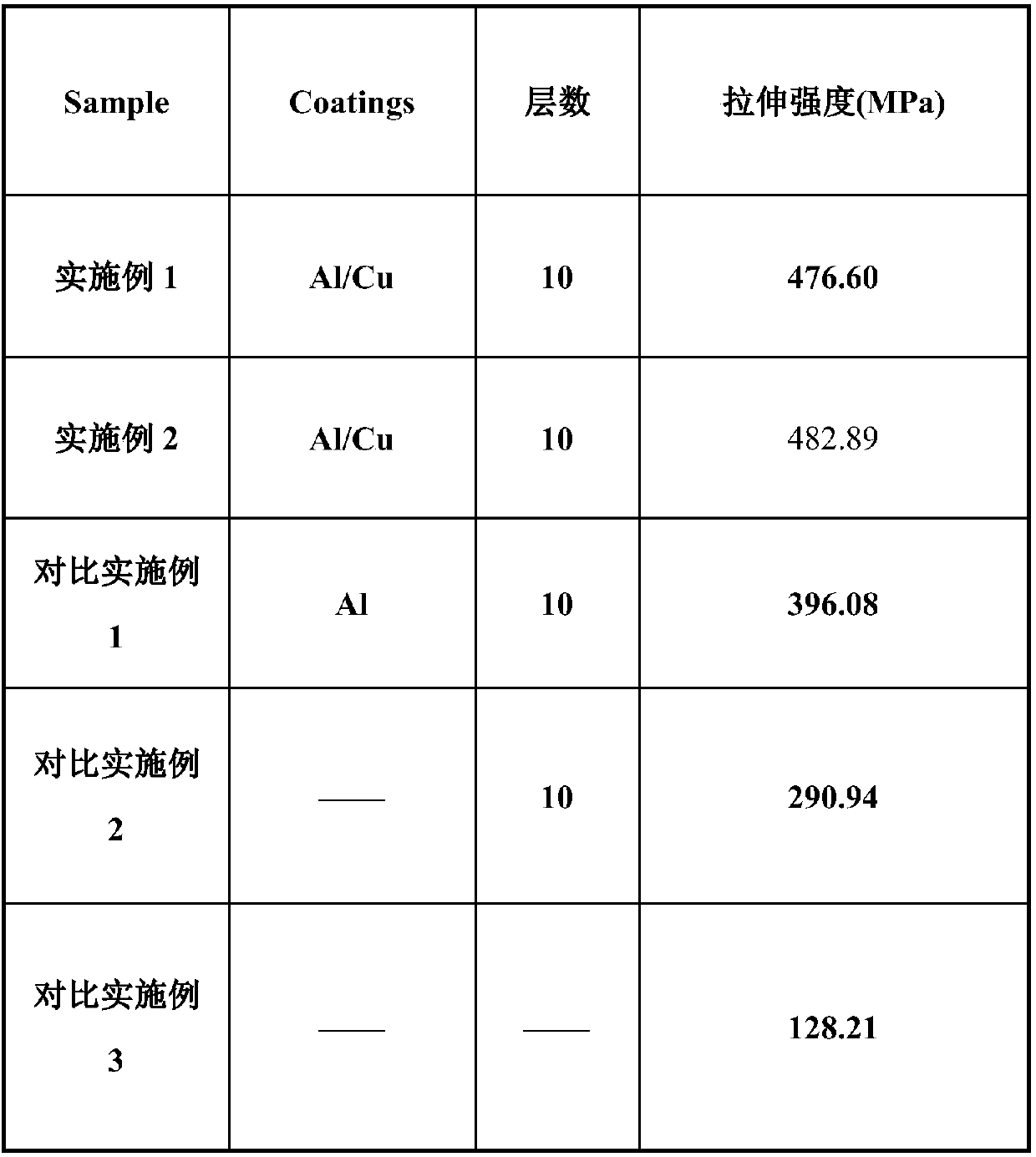

[0036] Example 1 is a SiC continuous fiber-reinforced Al-based composite material containing Al / Cu double coating, the fiber is coated by magnetron sputtering, the working temperature is 270°C, the sputtering gas is Ar, and the working pressure is 0.3Pa. The Al target sputtering power is 950W, the deposition time is 100min, the coating thickness is about 500nm, the Cu target sputtering power is 900W, the deposition time is 10min, the coating thickness is about 50nm, the total deposition time is 120min, and the total coating thickness is 550nm about. The number of prefabricated fiber layers is 10, and then the SiC continuous fiber-reinforced Al-based composite material is prepared by vacuum pressure impregnation method. The tensile strength is 476.60MPa.

Embodiment 2

[0038] Example 2 is a SiC continuous fiber-reinforced Al-based composite material containing Al / Cu double coating, the fiber is coated by magnetron sputtering, the working temperature is 270°C, the sputtering gas is Ar, and the working pressure is 0.3Pa. Al target sputtering power is 950W, deposition time is 160min, coating thickness is about 800nm, Cu target sputtering power is 900W, deposition time is 20min, coating thickness is about 100nm, total deposition time is 180min, total coating thickness is 900nm about. The number of prefabricated fiber layers is 10, and then the SiC continuous fiber-reinforced Al-based composite material is prepared by vacuum pressure impregnation method. The tensile strength is 482.89MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com