Preparation method of rosuvastatin calcium intermediate

A technology of rosuvastatin calcium and intermediates, applied in the field of organic synthesis, can solve the problems of high price, unfavorable industrial production, low reaction yield and the like, and achieves the effects of simple processing, overcoming harmful emissions and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

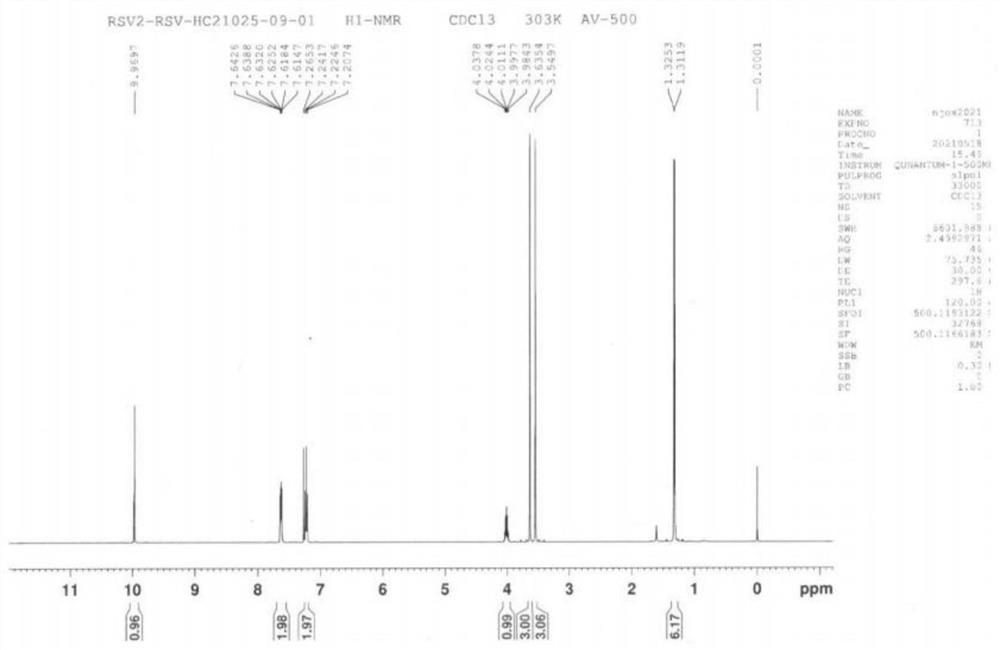

Image

Examples

preparation example Construction

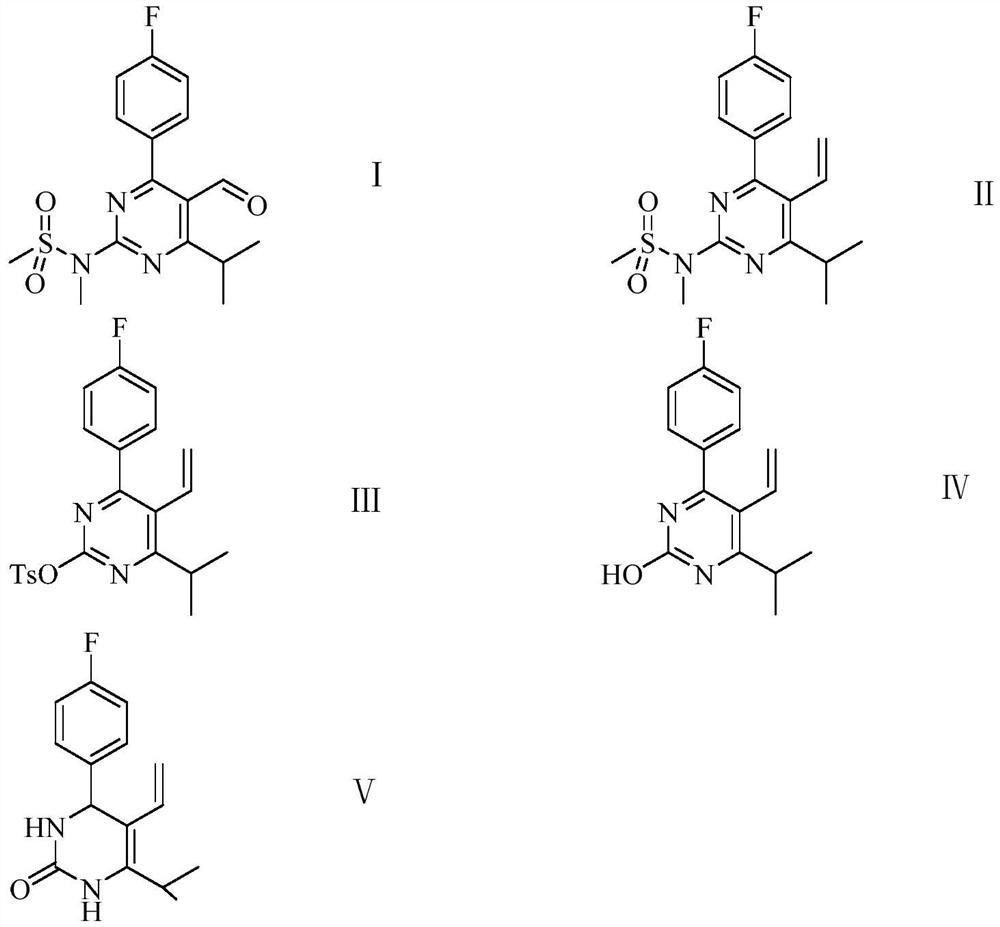

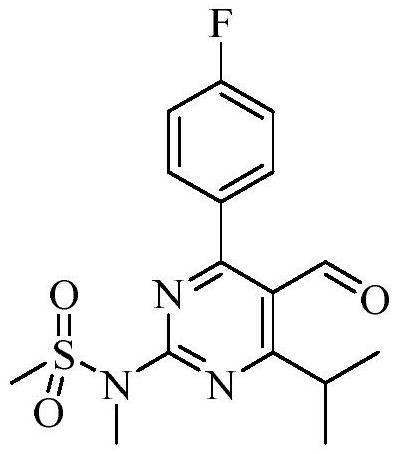

[0032] A preparation method of rosuvastatin calcium intermediate comprises:

[0033] Step (1), taking p-fluorobenzaldehyde, 2-methyl-3-carbonyl-5-hexene and urea as raw materials to synthesize compound V under the effect of metal catalytic salt;

[0034] Step (2), using an oxidant to oxidize the compound V to obtain the compound IV;

[0035] In step (3), the hydroxyl group of the compound IV is protected to obtain the compound III;

[0036] In step (4), compound III is reacted with N-methylmethanesulfonamide to generate compound II;

[0037] In step (5), compound I is obtained by oxidizing the compound II with ozone,

Embodiment 1

[0039] A preparation method of rosuvastatin calcium intermediate, the concrete steps are:

[0040]

[0041] (1) Synthesis of compound V

[0042] To the reactor were added 2-methyl-3-carbonyl-5-hexene (22.4g, 0.2mol), p-fluorobenzaldehyde (24.8g, 0.2mol), urea (21g, 0.35mol), cuprous chloride (200mg, 0.002mol), sulfuric acid (2ml) and ethanol (250ml), the temperature was raised to reflux, and the reaction was stirred for 16h. After detecting that the reaction was complete, it was cooled to room temperature and a solid was precipitated, suction filtered and dried to obtain compound V (49.5 g, 0.19 mol) with a yield of 95% and a purity of 99.4%.

[0043] (2) Synthesis of compound IV

[0044] Add compound V (39g, 0.15mol) to the reactor, slowly add 60% nitric acid (120ml), then add sodium nitrite (2g, 0.03mol), react at room temperature for 1h, after detecting the reaction is complete, add saturated sodium bicarbonate solution Neutralize and wash, there is solid precipitatio...

Embodiment 2

[0050] (1) Synthesis of compound V

[0051] To the reactor were added 2-methyl-3-carbonyl-5-hexene (22.4g, 0.2mol), p-fluorobenzaldehyde (24.8g, 0.2mol), urea (14.7g, 0.2mol), chloroform Copper (200mg, 0.002mol), sulfuric acid (2ml) and ethanol (250ml) were heated to reflux, and the reaction was stirred for 16h. After detecting that the reaction was completed, it was cooled to room temperature and a solid was precipitated, which was filtered and dried to obtain compound V (41.6 g, 0.16 mol) with a yield of 80% and a purity of 99.2%.

[0052] (2) Synthesis of compound IV

[0053]Compound V (39g, 0.15mol) was added to the reactor, 50% nitric acid (120ml) was slowly added, then sodium nitrite (2g, 0.03mol) was added, and the reaction was carried out at room temperature for 1h. After the reaction was detected, saturated sodium bicarbonate solution was added. Neutralize and wash, there is solid precipitation, suction filtration, and drying to obtain compound IV (33.6 g, 0.13 mol)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com