Preparation method of long-carbon-chain polyamide based on pentanediamine

A technology of carbon chain polyamide and pentamethylenediamine, which is applied in the field of preparation of long carbon chain polyamide, and can solve the problems of strength, barrier property, and insulation performance reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

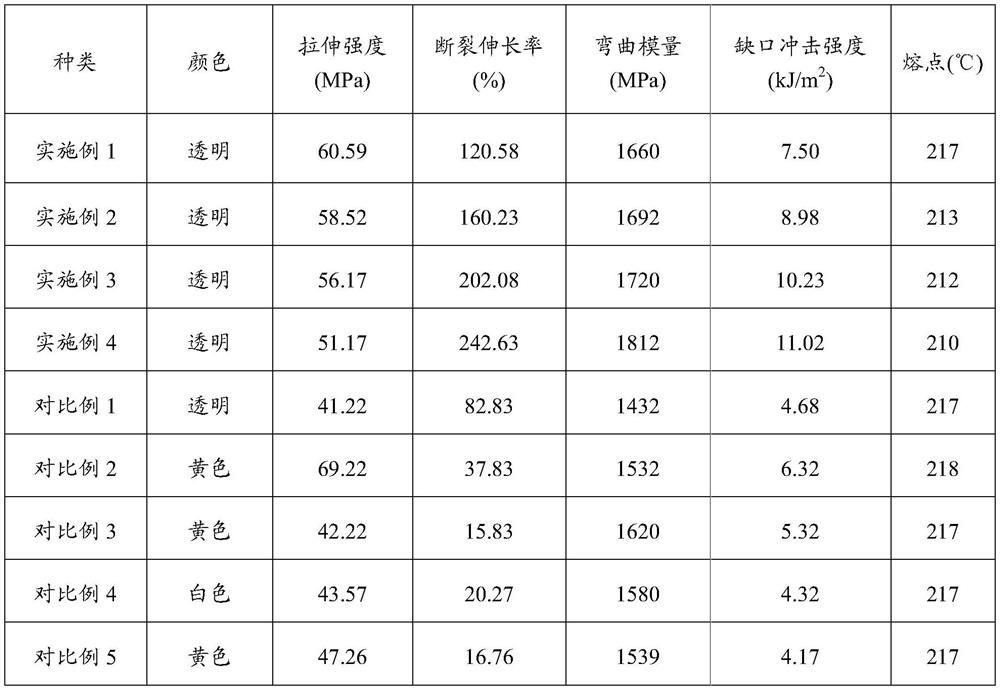

Examples

Embodiment 1

[0056] (1) take by weighing 104 parts of pentamethylenediamine, 202 parts of sebacic acid and 150 parts of deionized water, join in the salt-forming kettle, open stirring, set rotating speed to be 80rpm, set temperature to be 60 ℃, constant temperature reaction 40min, then adjust The pH value of the solution is 7.5, and a clear and transparent polyamide salt solution with a solution concentration of 50wt% is obtained;

[0057] (2) adding above-mentioned polyamide salt solution into the reactor, then adding 0.6 part of sodium hypophosphite, 0.6 part of antioxidant B215 and 4 parts of sebacic acid; replace the air in the kettle three times with nitrogen, then fill with nitrogen Make the pressure in the kettle 0.1MPa, turn on stirring, and set the stirring speed to 150rpm; finally, program the temperature rise, as follows:

[0058] 1) be warming up to 180 ℃, constant temperature reaction 60min, make polyamide salt fully prepolymerize;

[0059] 2) The temperature is raised to 210...

Embodiment 2

[0065] (1) take by weighing 104 parts of pentamethylene diamine, 216 parts of undecanedioic acid and 160 parts of deionized water, join in the salt-forming kettle, open stirring, set rotating speed to be 80rpm, set temperature to be 65 ℃, constant temperature reaction 60min, Then adjust the pH value of the solution to 7.6 to obtain a clear and transparent polyamide salt solution with a solution concentration of 50wt%;

[0066] (2) adding above-mentioned polyamide salt solution into the reactor, then adding 0.6 part of sodium hypophosphite, 0.6 part of antioxidant B215 and 4 parts of undecanedioic acid; replace the air in the kettle three times with nitrogen, then fill with Introduce nitrogen to make the pressure in the kettle be 0.1MPa, turn on stirring, and set the stirring speed to 150rpm; finally, program the temperature rise, as follows:

[0067] 1) be warming up to 185 ℃, constant temperature reaction 60min, make polyamide salt fully prepolymerize;

[0068] 2) The temper...

Embodiment 3

[0074] (1) take by weighing 104 parts of pentamethylene diamine, 230 parts of dodecanedioic acid and 170 parts of deionized water, join in the salt-forming kettle, open stirring, set rotating speed to be 80rpm, set temperature to be 70 ℃, constant temperature reaction 60min, Then adjust the pH value of the solution to 7.7 to obtain a clear and transparent polyamide salt solution with a solution concentration of 50wt%;

[0075] (2) above-mentioned polyamide salt solution is added in the reactor, then add 0.6 part of sodium hypophosphite, 0.8 part of antioxidant B215 and 3 parts of dodecanedioic acid; replace the air in the still with nitrogen three times, then fill with Introduce nitrogen to make the pressure in the kettle be 0.1MPa, turn on stirring, and set the stirring speed to 150rpm; finally, program the temperature rise, as follows:

[0076] 1) be warming up to 190 ℃, constant temperature reaction 60min, make polyamide salt fully prepolymerize;

[0077] 2) The temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com