Single-layer graphene multifunctional composite fiber melt spinning equipment and process

A single-layer graphene and composite fiber technology, applied in the field of spinning, can solve the problems of low production quality of composite fibers, achieve stable and uniform wind force, high cooling uniformity, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

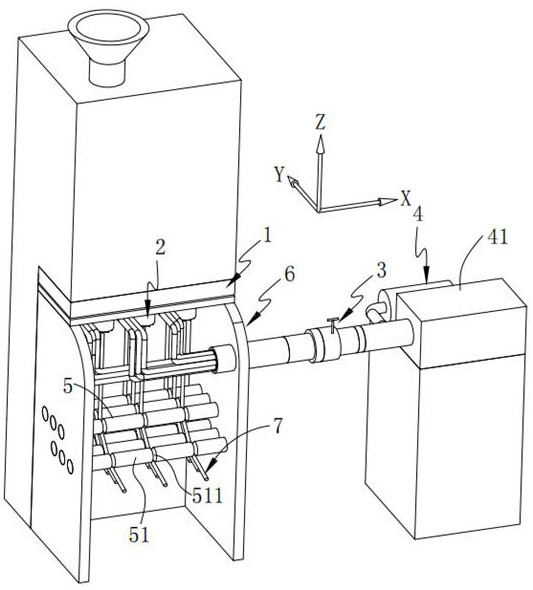

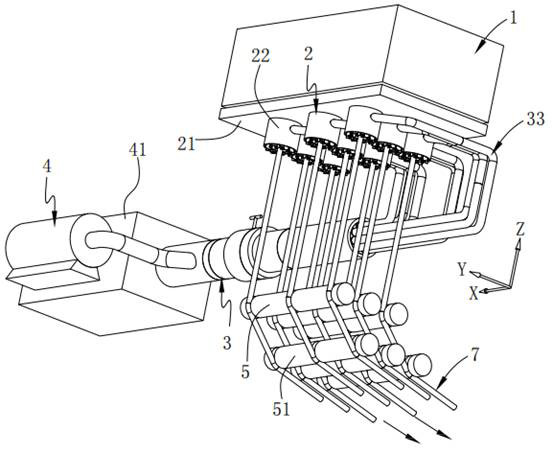

[0077] like Figure 1-5 As shown, the present invention provides a single-layer graphene multifunctional composite fiber melt spinning equipment, comprising: a spinneret 1;

[0078] Cooling unit 2, the cooling unit 2 for uniformly cooling and blowing along the discharge direction of the composite fibers 7 is arranged directly below the spinneret 1;

[0079] The conveying unit 3, the conveying unit 3 for providing the cooling unit 2 with small fluctuation and uniform wind power is communicated with the cooling unit 2; the other end of the conveying unit 3 is connected with the first air supply member 4 and the second air supply member 41 at the same time ;

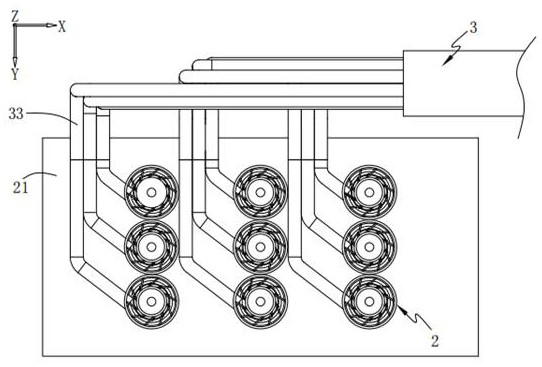

[0080] The cooling unit 2 includes:

[0081] mounting plate 21;

[0082] Concentric double pipes 22 with different diameters; the double pipes 22 are arranged on the mounting plate 21 along the conveying direction of the composite fibers 7 and have a minimum inner diameter greater than the diameter of the composite fiber...

Embodiment 2

[0112] like Figure 1-12 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is: Figure 9-12 As shown, the wind wave adjustment assembly 31 includes: a rotating shaft 311;

[0113] air-equalizing blades 312 evenly distributed on the axial surface of the rotating shaft 311;

[0114] a bottomed shaft sleeve 313 sleeved on one end of the rotating shaft 311 and adjacent to one side of the air equalizing component 32 and connected with the pipe body 31;

[0115] a first magnet 314 disposed in the shaft sleeve 313 and a second elastic member 315 connecting the first magnet 314 and the bottom of the shaft sleeve 313;

[0116] a second magnet 316 that cooperates with the first magnet 314 and repels the same and...

Embodiment 3

[0138] like Figure 1-13 As shown, the present embodiment provides a process for producing a composite fiber by a single-layer graphene multifunctional composite fiber melt spinning device, comprising the following steps:

[0139] Step 1. The second air supply member 41 supplies air to the conveying unit 3, and the conveying unit 3 automatically adjusts the size and uniformity of the wind power obtained by itself, so as to output a uniform and stable wind power and deliver it to the cooling unit through the first conveying pipe 33. unit 2;

[0140] Step 2: After the cooling unit 2 blows out the cooling air stably, the spinneret 1 evenly sprays the composite fibers 7 downward, and the cooling unit 2 blows air along the conveying direction of the composite fibers 7 to uniformly cool the composite fibers 7;

[0141] Step 3. During the process of step 1, when the wind power provided by the second air supply member 41 is less than the standard wind power, the first air supply memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com