SURP control device, method for adjusting nitrogen oxide conversion rate and automobile

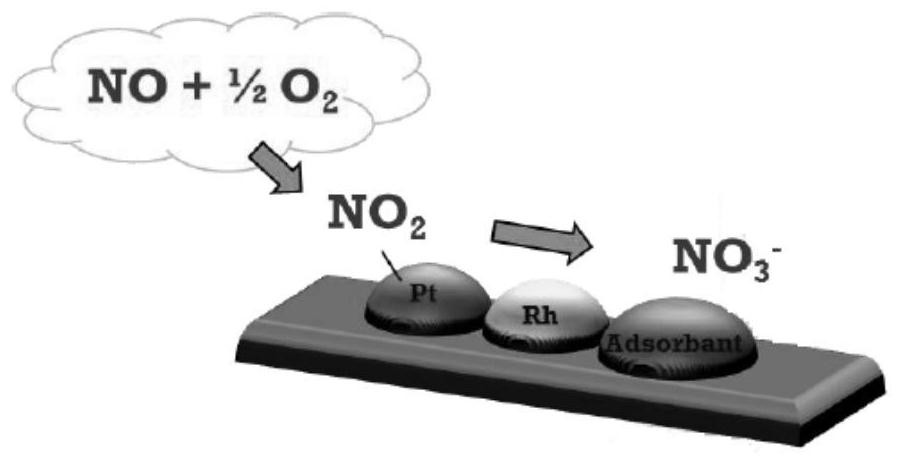

A control device, nitrogen oxide technology, applied in electrical control, engine control, fuel injection control, etc., can solve the problem of increased LNT development cost, and achieve the effect of reducing CO2 output, openness, and low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

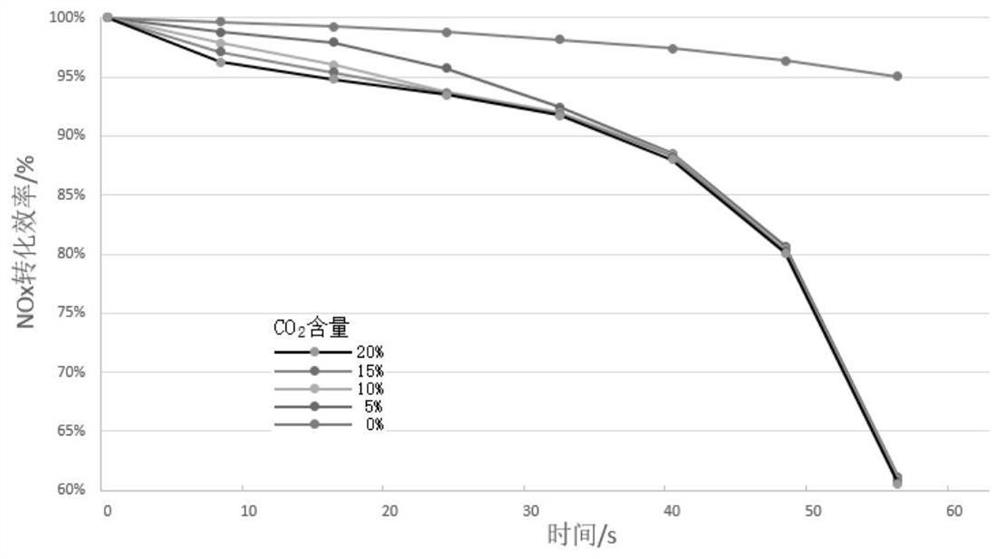

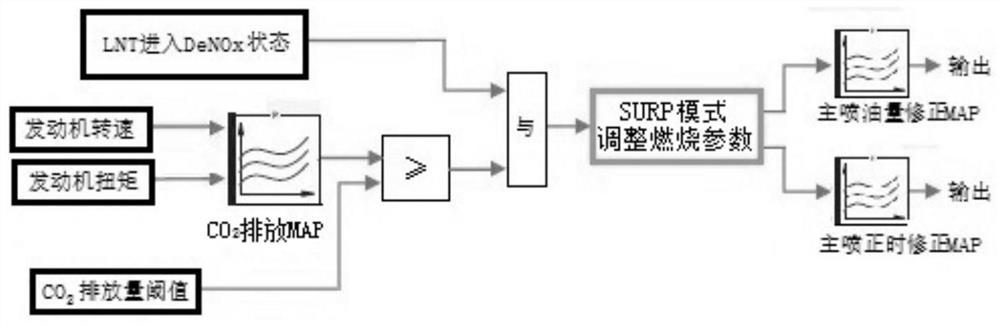

[0071] In this embodiment, the SURP control device is used to regulate the main injection quantity and main injection timing of the engine to reduce CO 2 The proportion of emissions in the exhaust gas, thereby reducing the CO in the exhaust gas 2 The effect on the conversion efficiency of LNT is to achieve the purpose of improving the conversion efficiency of LNT to NOx. The specific method for adjusting the nitrogen oxide conversion rate in the LNT is as follows:

[0072] The engine ECU control system monitors the current working state of the LNT, and when it is detected that the working state of the LNT is in the DeNOx state, the engine ECU control system performs the work of selecting the engine speed and engine torque. Among them, the range of engine speed selection points is 1200rpm-2800rpm, and the step size is 400rpm; the range of engine torque selection points is 50Nm to 300Nm, and the step size is 50Nm.

[0073] According to the above step size, the measured main in...

Embodiment 2

[0092] In this embodiment, the SURP control device is used to regulate the main injection quantity and main injection timing of the engine to reduce CO 2 The proportion of emissions in the exhaust gas, thereby reducing the CO in the exhaust gas 2 The effect on the conversion efficiency of LNT is to achieve the purpose of improving the conversion efficiency of LNT to NOx. The specific method for adjusting the nitrogen oxide conversion rate in the LNT is as follows:

[0093] The engine ECU control system monitors the current working state of the LNT, and when it is detected that the working state of the LNT is in the DeNOx state, the engine ECU control system performs the work of selecting the engine speed and engine torque. Among them, the range of engine speed selection points is 1200rpm-2800rpm, and the step size is 100rpm; the range of engine torque selection points is 50Nm to 300Nm, and the step size is 25Nm.

[0094] According to the above step size, the measured main in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com