Garbage incineration denitration reaction dynamic control method and system based on big data technology

A big data technology and waste incineration technology, which is applied in the field of dynamic control of waste incineration and denitrification reaction, can solve the problems of lag and delay, difficulty in timely and accurate adjustment of reducing agent flow, unstable calorific value, etc., so as to solve the problems of lag and delay performance. , to avoid excessive ammonia injection phenomenon, to meet the effect of stable operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

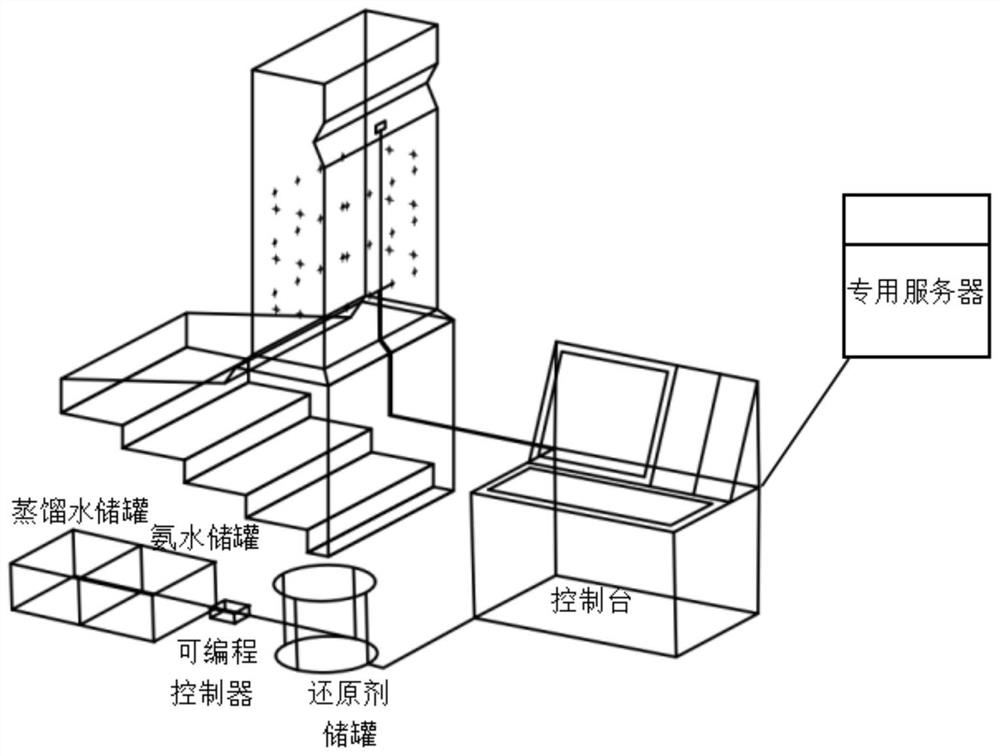

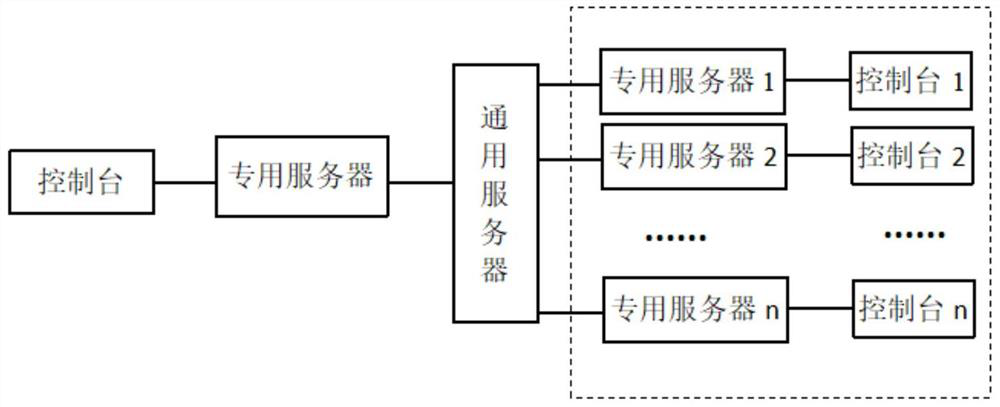

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. The embodiments cannot be repeated here, but the embodiments of the present invention are not limited to the following embodiments.

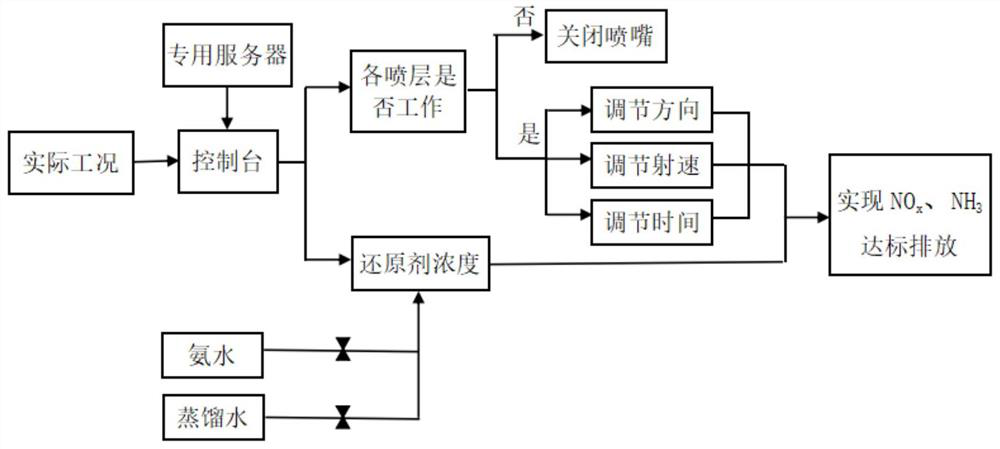

[0029] The invention provides a dynamic control method for waste incineration and denitrification reaction based on big data technology, which can automatically adjust the working state according to the real-time working conditions in the furnace, such as Figure 4 As shown, the steps of the method are as follows:

[0030] S1: The dedicated server collects the working condition data of the incinerator, and uniformly standardizes the valid data in the working condition data; the dedicated server identifies the working parameters of the optimum ammonia escape amount under each working condition, and when the When the escape amount of ammonia is smaller, the working parameter of the smaller ammonia escape amount is repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com