Device for measuring velocity and structure of detonation wave under action of liquid drops and control method thereof

A control method and technology of measuring device, which can be applied in the direction of measuring device, measuring rapid change, material excitation analysis, etc., can solve the problem of lack of sufficient understanding of the mechanism of action, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

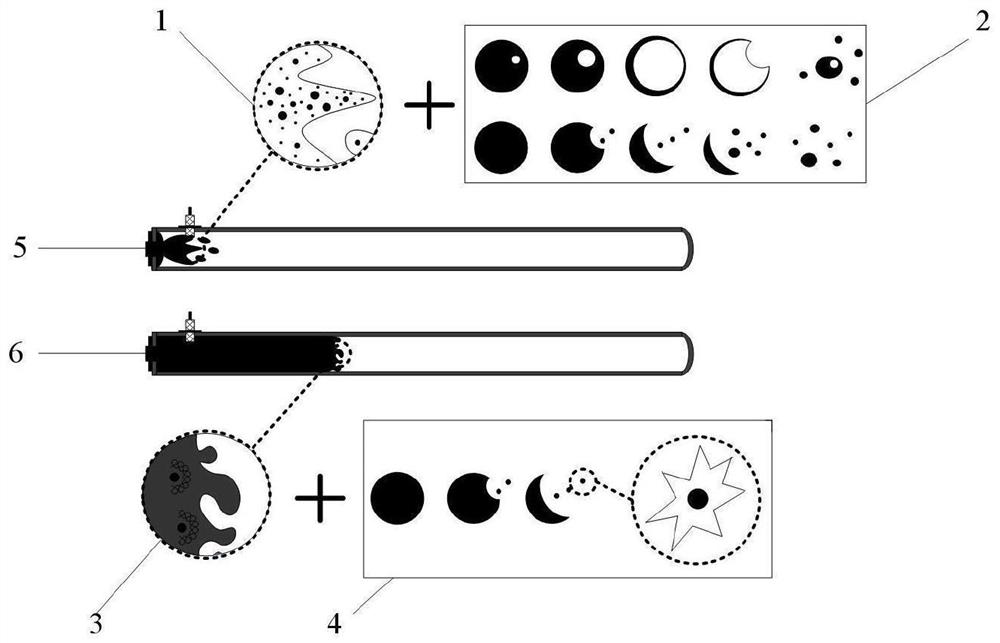

Problems solved by technology

Method used

Image

Examples

Embodiment 1

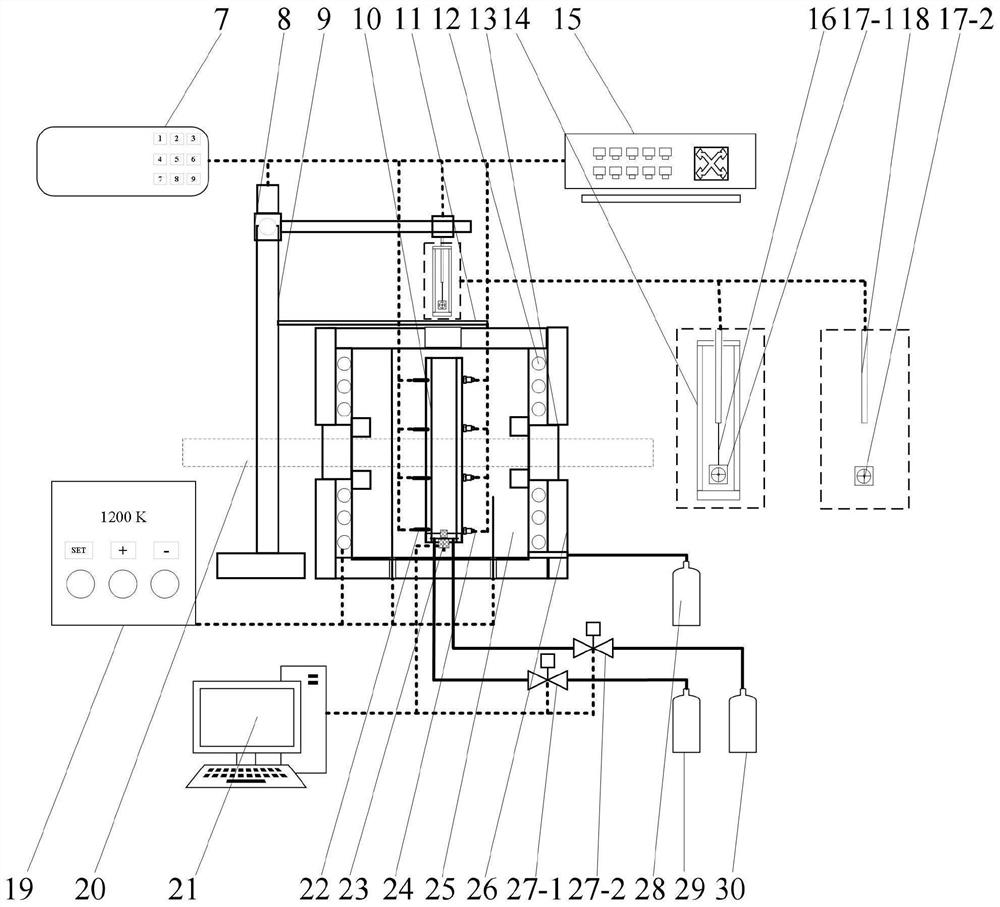

[0027] see figure 2 , In this example, a hanging droplet generation device is used, which includes a stepping motor 8 , a ball screw moving rod 9 , a heat shield 14 and a hanging wire 16 . Using the stepper motor controller 7, the stepper motor 8, and the ball screw moving rod 9, the hanging method droplet 17-1 is extended into the optical observation area of the detonation tube. The depth of this penetration can be determined by the stepper motor controller 7 Take control. The droplets are heated by the heating chamber 25 with the resistance wire 12, the heating temperature is controlled by the temperature controller 19, and the thermocouple 22 monitors the temperature of the heating chamber in real time. Through the optical observation area 20, using the schlieren technique, the time when the droplet begins to microburst is measured. In the detonation tube 10, ethylene / air is used to generate a detonation wave, and the computer 21 is used to control the supply of fuel a...

Embodiment 2

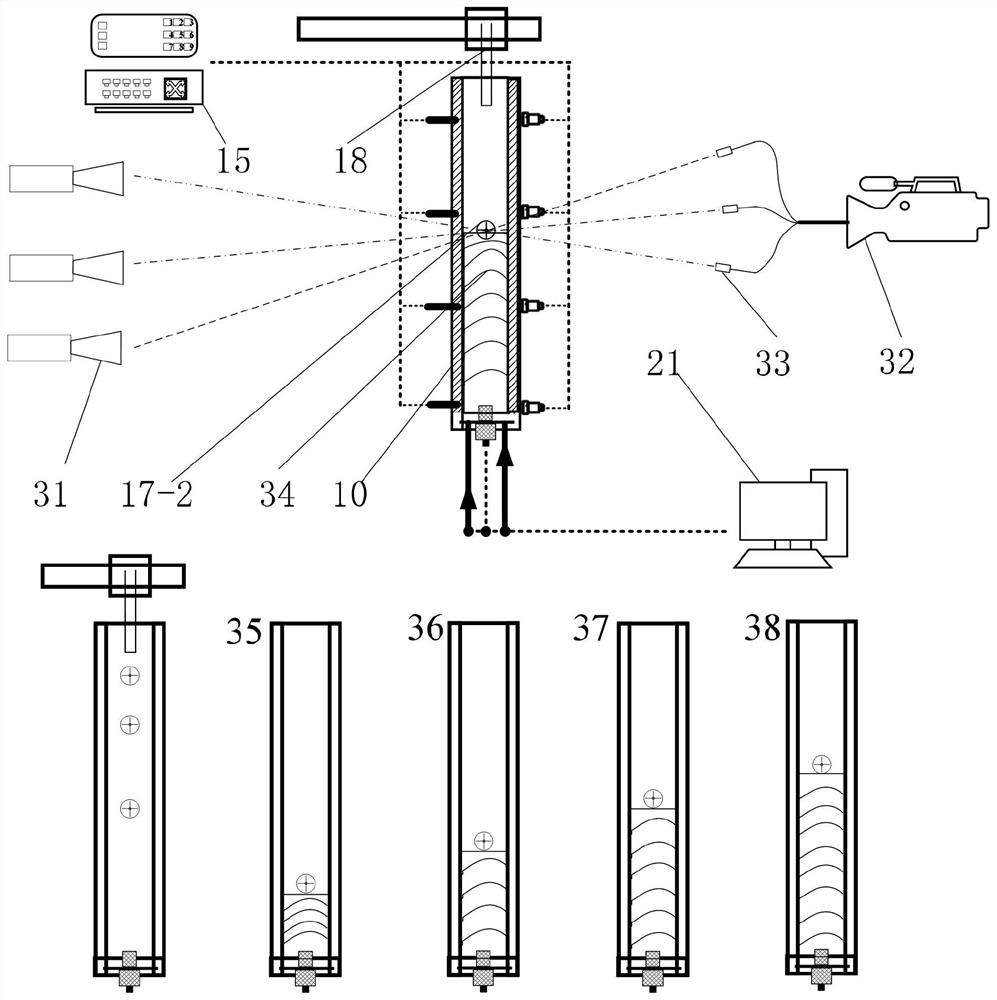

[0029] see image 3 , In this example, the droplet method 17-2 is suspended on the droplet generator 18, and the droplet method 17-2 is controlled by the droplet generator 18 to drop into the detonation tube whose initial temperature has been set 10. In the detonation tube 10, ethylene / air is used to initiate the detonation wave, and the computer 21 controls the droplet method droplet 17-2 to fall and the trigger sequence of the gas phase detonation wave 34 to start, so that the droplet and the slow combustion wave stage 35, The flame / detonation wave phases in different development stages such as the turbulent flame acceleration stage 36 , the overdrive detonation stage 37 and the stable detonation stage 38 . Use the pressure / temperature signal acquisition instrument 15 and the three-dimensional optical diagnostic system (including multiple groups of light sources 31, multi-probe optical fiber beams 33 and high-speed cameras 32) to measure the propagation velocity and cell str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com