Missile-borne ultrahigh-temperature flexible low-loss radio frequency coaxial cable

A radio frequency coaxial cable, ultra-high technology, applied in the direction of coaxial cable/analog cable, insulated cable, cable, etc., can solve the problem that the temperature performance of flexible low-loss cables cannot meet the requirements of use, and high-temperature-resistant cables do not have soft, low-temperature Loss, inability to apply low loss and bending requirements, etc., to achieve good electrical conductivity, strong passivation ability, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

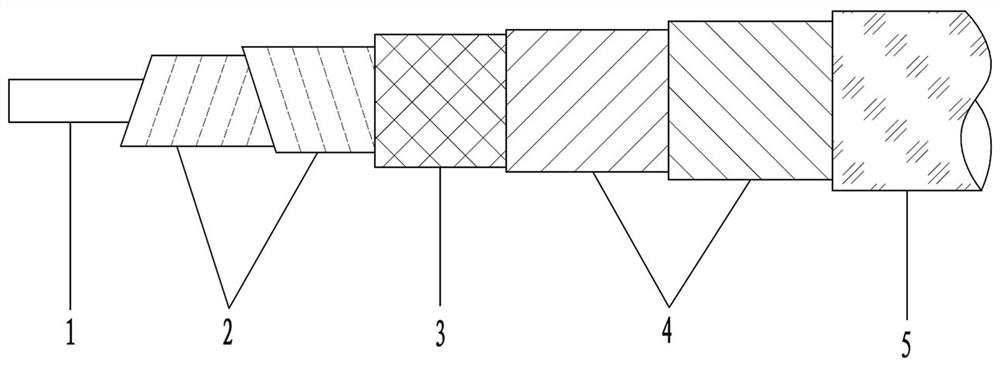

[0019] The first embodiment: as figure 1 As shown in the figure, an ultra-high temperature flexible radio frequency coaxial cable for bomb-borne use includes a conductor 1, an insulating layer 2, a shielding layer 3, a barrier layer 4 and a protective sheath arranged on the outside of the conductor 1 in turn. The conductor 1, the insulating layer 2 , the shielding layer 3, the blocking layer 4 and the protective cover 5 are all high temperature resistant materials, the protective cover 5 is a flexible material, and the insulating layer 2 is a low dielectric loss material.

[0020] The insulating layer 2 includes multiple layers of quartz fiber cloth wrapped around the outside of the conductor 1 .

[0021] The winding directions of the quartz fiber cloth between adjacent layers are opposite.

[0022] The blocking layer 4 is a quartz fiber cloth wrapped between the shielding layer 3 and the protective cover 5 .

[0023] A barrier layer 4 composed of quartz fiber cloth is also ...

no. 2 example

[0031] The difference between this embodiment and the first embodiment is that the winding directions of the multilayer quartz fiber cloths in the insulating layer are the same.

[0032] In the present invention, unless otherwise expressly specified and limited, for example, it may be a fixed connection, a detachable connection, or an integrated; it may be a mechanical connection or an electrical connection; it may be a direct connection or a The indirect connection through an intermediate medium may be the internal communication between two elements or the interaction relationship between the two elements. Unless otherwise explicitly defined, those of ordinary skill in the art can understand the above terms in the present invention according to specific circumstances. specific meaning in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com