Preparation method of ultralow-temperature battery

An ultra-low temperature, battery technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow charging, time-consuming, less than full charge and discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The cathode slurry was prepared as follows:

[0037] Step a): Dissolve the binder in N-methylpyrrolidone (chemical formula abbreviated as NMP) solvent to prepare a binder liquid with a mass fraction of 10%, and then dissolve the carbon nanotubes and the dispersant in the NMP solvent to prepare into conductive paste;

[0038] Step b): Dissolve the conductive paste and the dried conductive carbon black in the binder solution, stir for 30 minutes, then add the dried ternary (Li(NiCoMn)O2) positive electrode material, and add an appropriate amount of NMP solvent Adjust the solid content to 55%, set the parameters (revolution 25r / min dispersion 1200r / min) and continue stirring for 4h;

[0039] Step c): under agitation of slow setting parameters (revolution 10r / min dispersion 500r / min), evacuating and degassing for 30min to obtain lithium ion battery positive electrode slurry

[0040] The anode slurry was prepared as follows:

[0041] Step a): Dissolve the binder in N-meth...

Embodiment 1

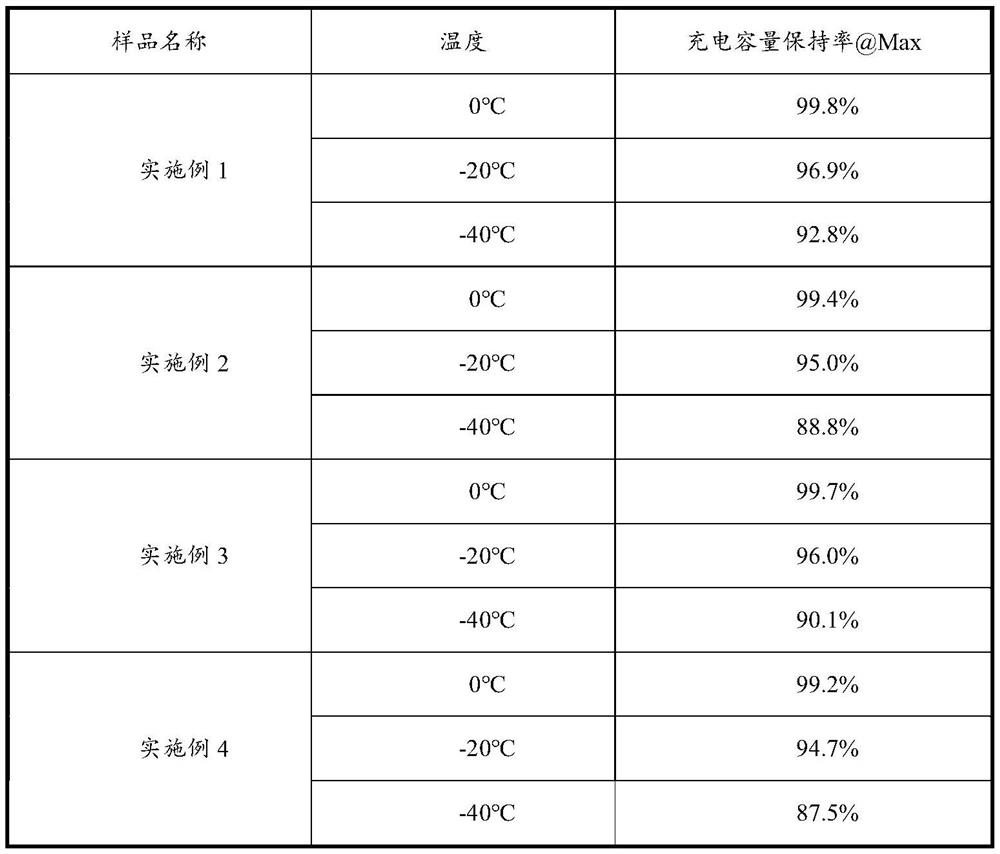

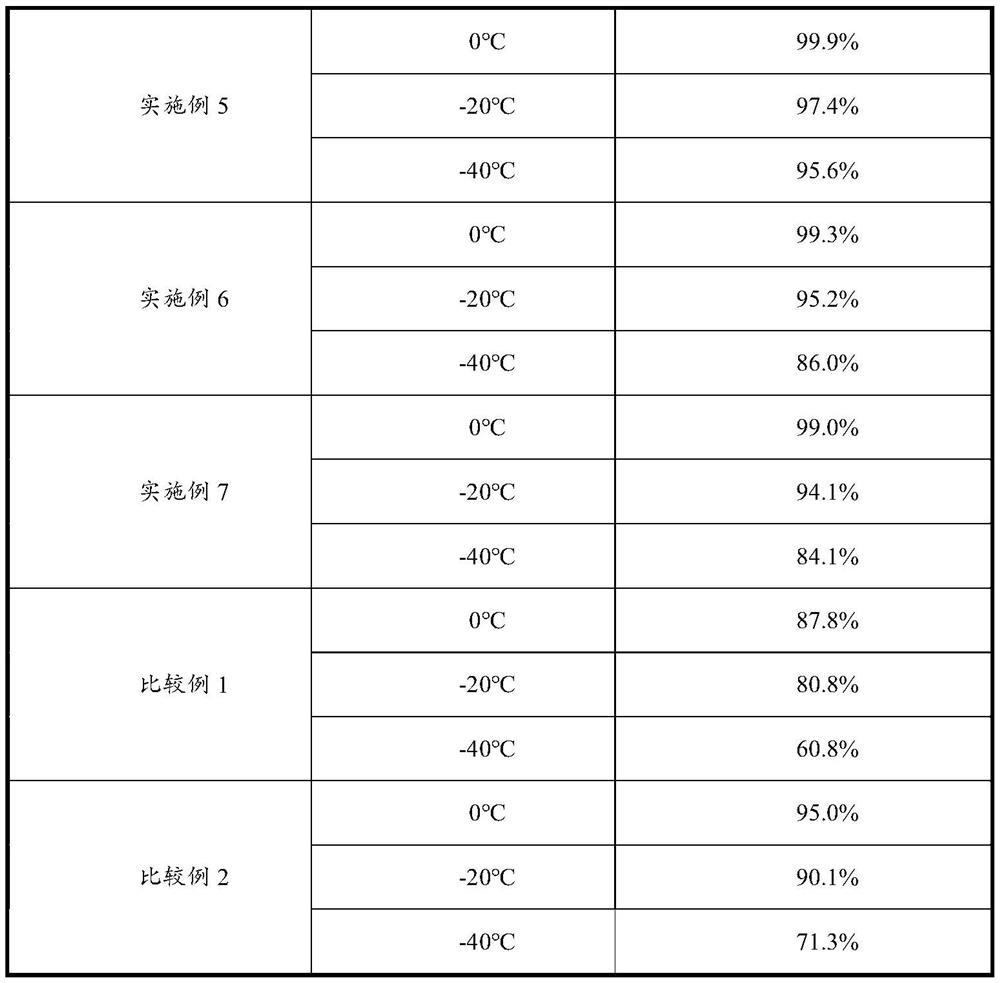

[0062] The low temperature capacity retention rate of Example 1 is significantly higher than that of Example 6, which proves the technical contribution of the heating process in the heat treatment method of the present application to the charging performance in a low temperature environment;

[0063] The low temperature capacity retention rate of Example 1 is significantly higher than that of Example 7, which proves the technical contribution of the process of heat preservation and pressure keeping in the heat treatment method of the present application to the charging performance in a low temperature environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com