Flaky atomic-scale Pt/CeO2 catalyst with ultrahigh Pt loading capacity and preparation method of flaky atomic-scale Pt/CeO2 catalyst

A catalyst and atomic-level technology, applied in the field of flake atomic-level Pt/CeO2 catalyst and its preparation, to achieve excellent stability, improved catalytic effect, and strong loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

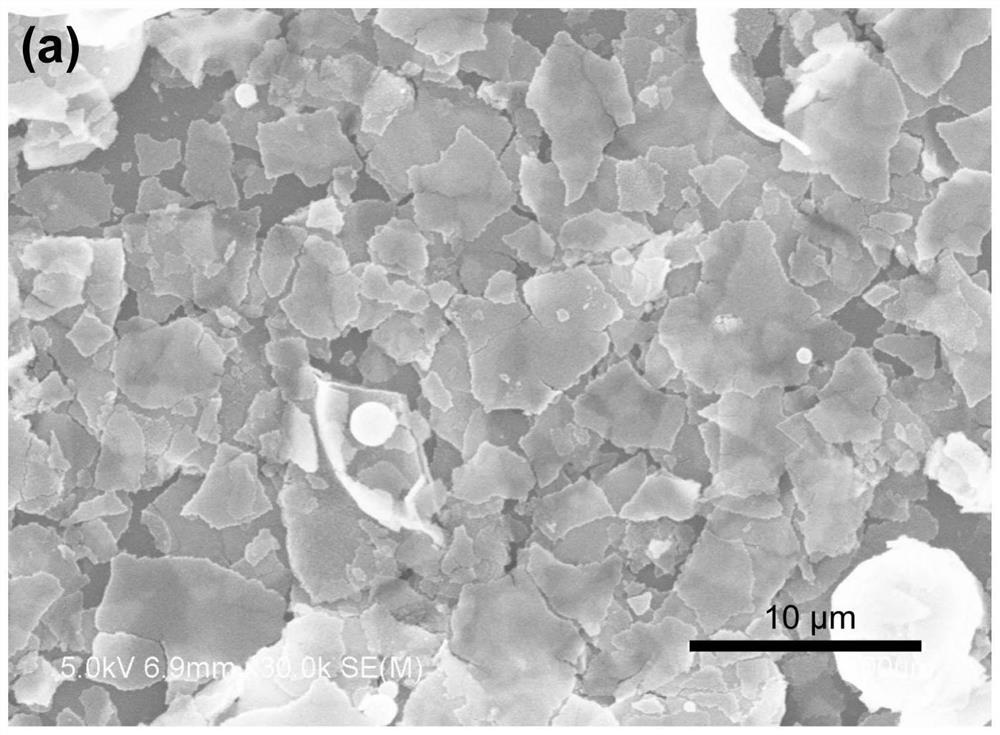

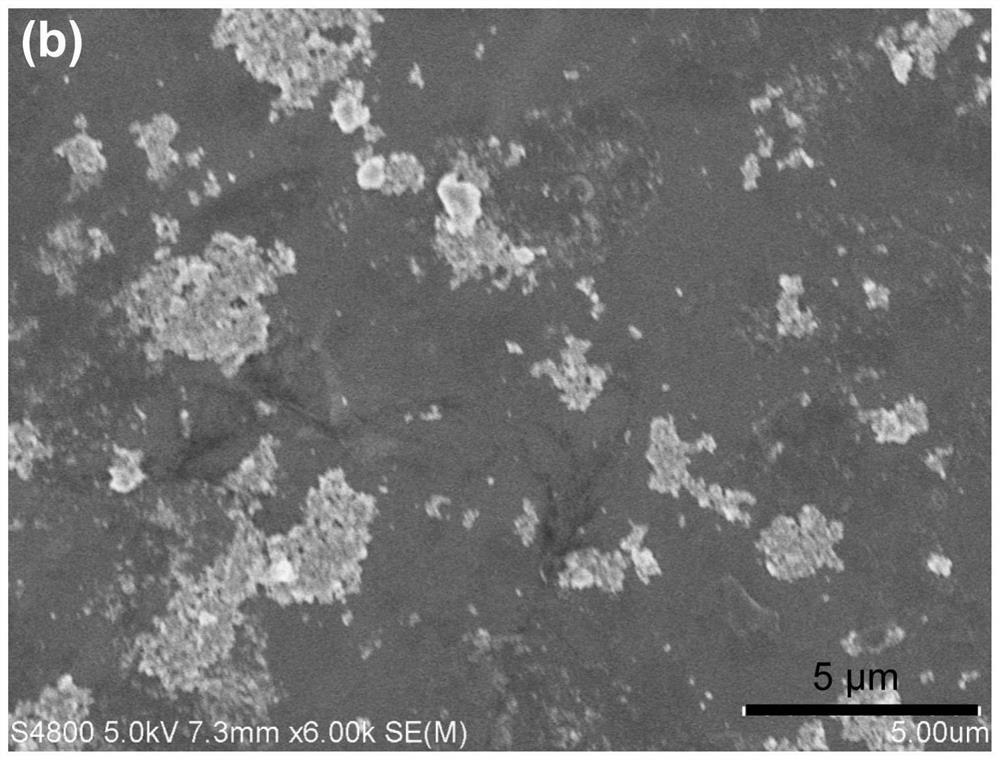

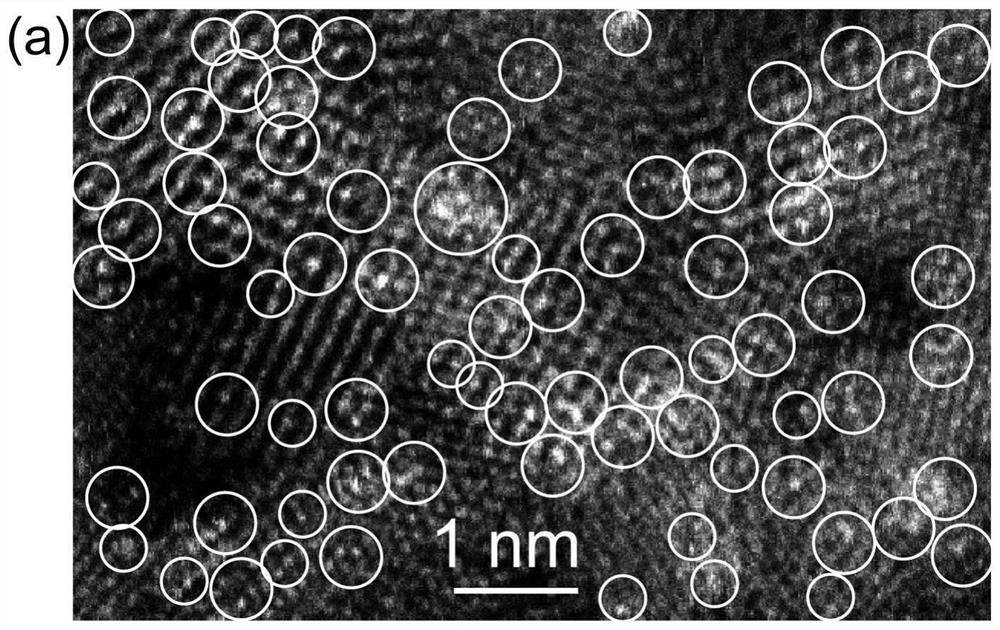

[0040] This embodiment provides an atomic-level Pt / CeO with ultra-high Pt loading 2 The preparation method of catalyst comprises the following steps:

[0041] Step 1: Dissolve 0.14 mmol of chloroplatinic acid, 2 mmol of cerium nitrate and 0.2 g of glucose in deionized water to form a 30 mL mixed solution;

[0042] Step 2: Pour the above mixed solution into the atomizer, and introduce the generated micro mist droplets into the tube furnace for high temperature treatment. The length of the heating zone of the tube furnace is 30cm and the temperature is 600°C, and collected at the other end of the tube furnace. orange-yellow powder;

[0043] Step 3: Heat treatment on the above orange-yellow powder at a temperature of 400°C to remove residual organic matter for 2 hours to obtain atomic-level Pt / CeO with 8% Pt loading 2 catalyst.

Embodiment 2

[0045] This embodiment provides an atomic-level Pt / CeO with ultra-high Pt loading 2 The preparation method of catalyst comprises the following steps:

[0046] Step 1: Dissolve 0.09 mmol of chloroplatinic acid, 2 mmol of cerium nitrate and 0.2 g of glucose in deionized water to form a 30 mL mixed solution;

[0047] Step 2: Pour the above mixed solution into the atomizer, and introduce the generated micro mist droplets into the tube furnace for high temperature treatment. The length of the heating zone of the tube furnace is 30cm and the temperature is 600°C, and collected at the other end of the tube furnace. orange-yellow powder;

[0048] Step 3: Heat treatment on the orange-yellow powder at a temperature of 400°C to remove residual organic matter for 2 hours to obtain atomic-level Pt / CeO with 5% Pt loading 2 catalyst.

Embodiment 3

[0050] This embodiment provides an atomic-level Pt / CeO with ultra-high Pt loading 2 The preparation method of catalyst comprises the following steps:

[0051] Step 1: Dissolve 0.18 mmol chloroplatinic acid, 2 mmol cerium nitrate and 0.2 g glucose in deionized water to form a 30 mL mixed solution;

[0052] Step 2: Pour the above mixed solution into the atomizer, and introduce the generated micro mist droplets into the tube furnace for high temperature treatment. The length of the heating zone of the tube furnace is 30cm and the temperature is 700°C, and collected at the other end of the tube furnace. orange-yellow powder;

[0053] Step 3: Heat treatment on the above orange-yellow powder at a temperature of 400°C to remove residual organic matter for 2 hours to obtain atomic-level Pt / CeO with 10% Pt loading 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com