Method for removing hydrogen sulfide from carbon disulfide

A carbon disulfide, hydrogen sulfide technology, applied in the direction of carbon disulfide, hydrogen sulfide, carbon-sulfur compounds, etc., can solve the problems of difficulty in realization and complicated adjustment of rectification tower parameters, and achieve the effect of reducing rectification steps and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides the following technical scheme: the carbon disulfide liquid containing hydrogen sulfide is gasified and converted into an absorption liquid, and the gas is separated and condensed to obtain carbon disulfide with a hydrogen sulfide content of less than 0.1 wt%; Absorption of hydrogen sulfide.

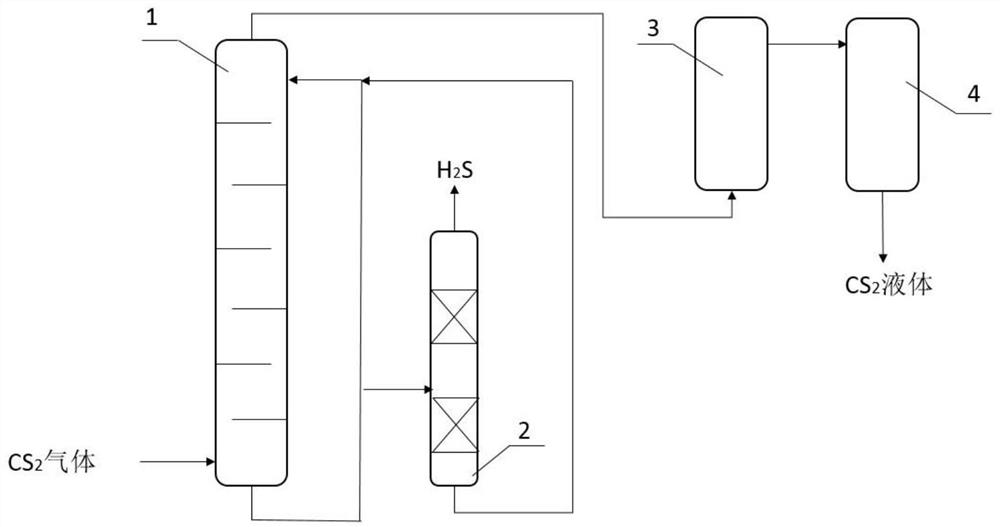

[0028] combine figure 1 The present invention is further described: the gasification of the carbon disulfide liquid containing hydrogen sulfide at normal pressure and temperature of 50 to 60 ° C is transferred into the lowermost tray of absorption tower 1, and the number of trays of absorption tower 1 is based on the amount of ventilation, the content of hydrogen sulfide and the active ingredient of the absorption liquid. factors such as changes. The absorption liquid is transferred from the tower kettle to the top of the tower, and the temperature of the top of the tower is 45-60 °C. Part of the absorption liquid is continuously transferred to the regenera...

Embodiment 2

[0030] Will figure 1 The shown device is used for carbon disulfide to remove hydrogen sulfide, wherein the diameter of absorption tower 1 is 1000mm, there are 8 trays, and the weir height is 200mm.

[0031] The specific content of the absorption liquid is as follows: triethanolamine is 50wt%, ethylene glycol is 5wt%, and the rest is water.

[0032] The temperature is 60°C, and the gas containing hydrogen sulfide 0.5v / v% carbon disulfide flows at a flow rate of 1000m 3 / h is passed into the absorption tower 1, the tower still liquid of the absorption tower 1 is circulated to the top of the tower at 100kg / h, the regenerated liquid is merged into the circulation at 67kg / h, the exhaust gas from the top of the absorption tower is passed into the gas-liquid separator 3, and the liquid phase part It is automatically transferred to the absorption tower 1 by gravity, and the gas phase part is condensed at 30 ℃ to obtain carbon disulfide liquid, and hydrogen sulfide is not detected. T...

Embodiment 3

[0034] Will figure 1 The shown device is used for carbon disulfide to remove hydrogen sulfide, wherein the diameter of absorption tower 1 is 1000mm, there are 8 trays, and the weir height is 200mm.

[0035] The specific content of the absorption liquid is as follows: N-methyldiethanolamine is 30wt%, diethylene glycol is 5wt%, and the rest is water.

[0036] The temperature is 55°C, the gas containing hydrogen sulfide 0.5v / v% carbon disulfide and the flow rate is 1000m 3 / h into the absorption tower 1, the tower liquid of the absorption tower 1 is circulated to the top of the tower at 200kg / h, the regenerated liquid is merged into the circulation at 110kg / h, the exhaust gas from the top of the absorption tower is passed into the gas-liquid separator, and the liquid phase part relies on gravity It is automatically transferred to the absorption tower, and the gas phase part is condensed at 30°C to obtain carbon disulfide liquid, wherein the hydrogen sulfide content is 0.04wt%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com