Aerogel inorganic fiber spraying material as well as preparation method and application thereof

An inorganic fiber spraying and aerogel technology, applied in climate change adaptation, climate sustainability, passive house, etc., can solve problems such as poor fire resistance, achieve outstanding waterproof performance, good strength, and improve fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

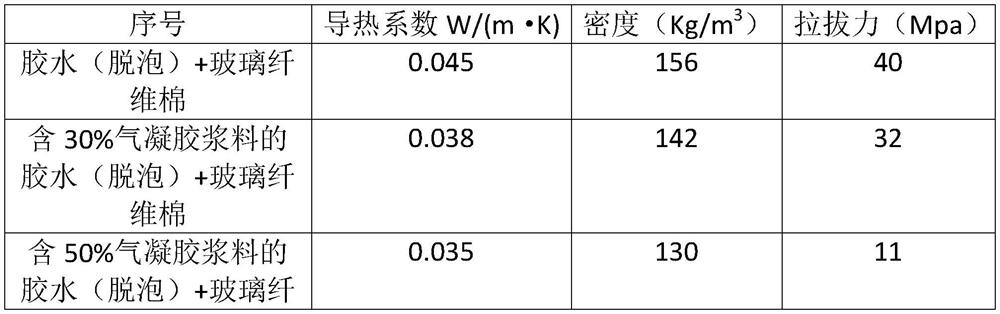

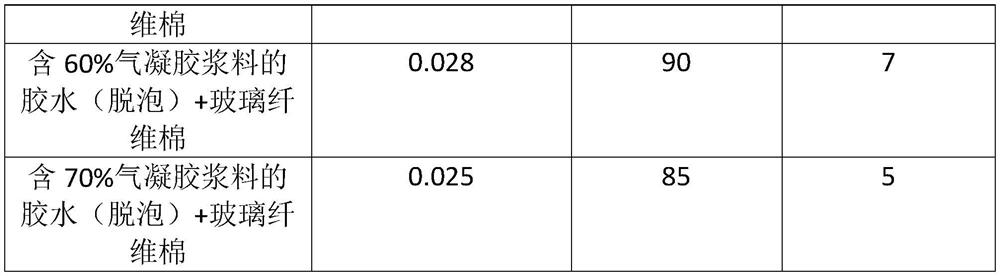

Examples

Embodiment 1

[0033] The preparation of aerogel inorganic fiber spraying material with aerogel slurry content of about 30wt% in the used glue includes the following steps:

[0034] 1) Mix 30 parts of aerogel slurry with a mass fraction of 15% with 55 parts of binder, then add 15 parts of water, 0.3 parts of anionic dispersant, 0.4 parts of polyacrylamide and 0.03 parts of of sodium alginate, stir evenly, and then carry out defoaming treatment to obtain glue;

[0035] 2) Put the fiber cotton into the rag and break it up;

[0036] 3) 1 part of fiber cotton and 10 parts of glue are loaded into the spraying machine for spraying construction;

[0037] 4) Use a shaping tool to reshape the surface to obtain the aerogel inorganic fiber spray material.

[0038] in:

[0039] The binder is PVA glue; the anionic dispersant is sodium oleate; the thickness of the aerogel inorganic fiber spray material is 30mm.

Embodiment 2

[0041] The preparation of aerogel inorganic fiber spraying material with aerogel slurry content of about 50wt% in the used glue includes the following steps:

[0042] 1) Mix 50 parts of aerogel slurry with a mass fraction of 15% with 35 parts of binder, then add 15 parts of water, 0.6 parts of anionic dispersant, 0.8 parts of polyacrylamide and 0.04 parts of Sodium alginate, stir evenly, and then carry out defoaming treatment to obtain glue;

[0043] 2) Put the fiber cotton into the rag and break it up;

[0044] 3) 1 part of fiber cotton and 10 parts of glue are loaded into the spraying machine for spraying construction;

[0045] 4) Use a shaping tool to reshape the surface to obtain the aerogel inorganic fiber spray material.

[0046] in:

[0047] The binder is 707 glue; the anionic dispersant is; the thickness of the aerogel inorganic fiber spraying material is the same as that of Example 1.

Embodiment 3

[0049] The preparation of aerogel inorganic fiber spraying material with aerogel slurry content of about 60wt% in the used glue includes the following steps:

[0050] 1) Mix 20 parts of aerogel slurry with a mass fraction of 15% with 10 parts of binder, and then add 3 parts of water, 0.6 parts of anionic dispersant, 0.6 parts of polyacrylamide and 0.3 parts of Sodium alginate, stir evenly, and then carry out defoaming treatment to obtain glue;

[0051] 2) Put the fiber cotton into the rag and break it up;

[0052] 3) 1 part of fiber cotton and 15 parts of glue are loaded into the spraying machine for spraying construction;

[0053] 4) Use a shaping tool to reshape the surface to obtain the aerogel inorganic fiber spray material.

[0054] in:

[0055] The binder is water glass; the anionic dispersant is sodium sulfonate; the thickness of the aerogel inorganic fiber spray material is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com