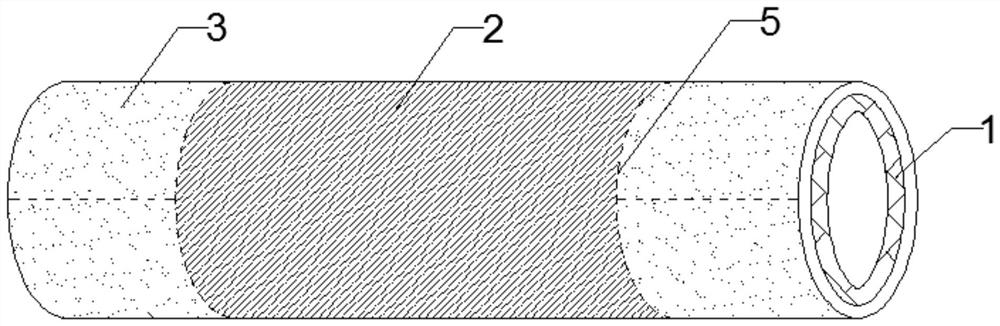

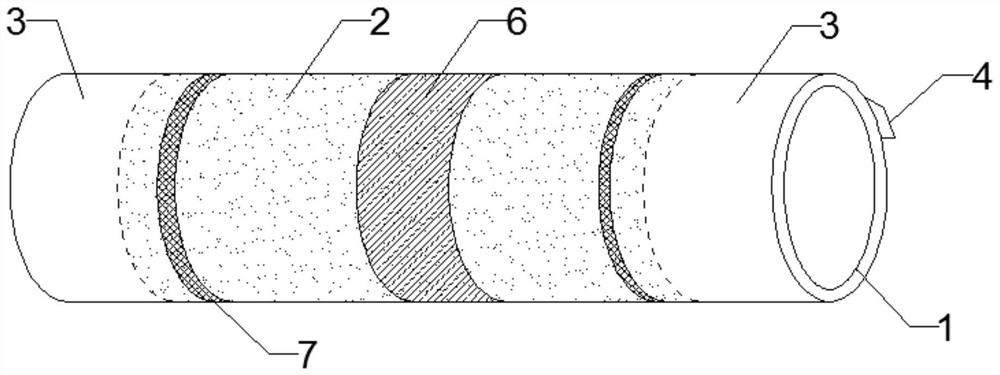

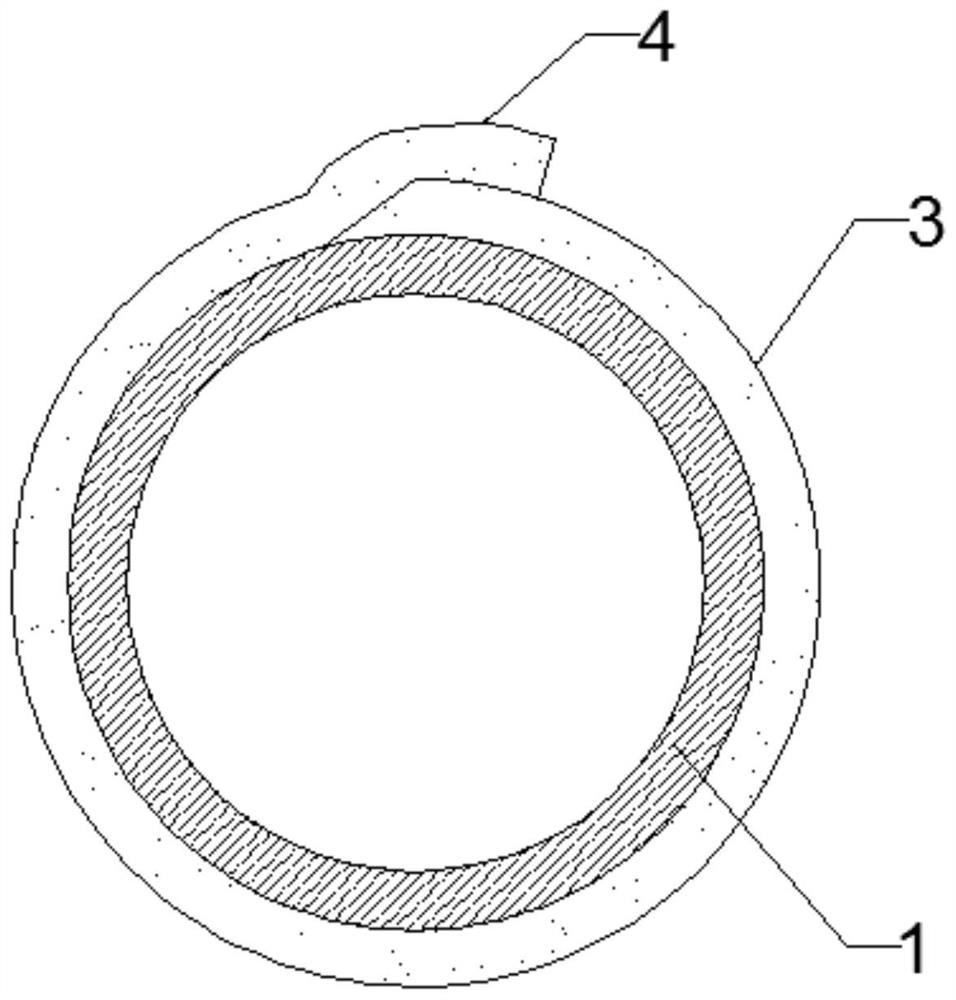

Preparation method of anti-termite protective layer and gas pipeline with protective layer

A gas pipeline and protective layer technology, which is applied in pipeline protection, pipeline damage/wear prevention, mechanical equipment, etc., can solve problems such as gas leakage, troublesome process, pipeline damage, etc., to improve safety reliability, safe and convenient connection, and extend the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of an anti-ant protective layer, comprising the following contents:

[0045] 1) Weigh each component according to the formula of the protective layer, add it to the mixer and mix, and release the material after mixing;

[0046] 2) Add the mixed material in step 1) into the twin-screw extruder for melt blending, and after the material comes out of the die in the twin-screw extruder, the protective layer is obtained by blow molding, which is recorded as the sample 1; The temperature of each zone of the twin-screw extruder is set as follows: the temperature of the first zone is 140-145°C, the temperature of the second zone is 160-165°C, the temperature of the third zone is 175-180°C, the temperature of the fourth zone is 190-200°C, and the temperature of the fifth zone is 190-200°C. The temperature of the zone is 205-210 ℃, and the temperature of the sixth zone is 220-225 ℃; the main engine speed of the twin-screw extruder is 250-300r / min, and the curr...

Embodiment 2

[0050] A preparation method of an anti-ant protective layer, comprising the following contents:

[0051] 1) Weigh each component according to the formula of the protective layer, add it to the mixer and mix, and release the material after mixing;

[0052] 2) Add the mixed material in step 1) into the twin-screw extruder for melt blending, and after the material comes out of the die in the twin-screw extruder, the protective layer is obtained by blow molding, which is recorded as the sample 2; The temperature of each zone of the twin-screw extruder is set as follows: the temperature of the first zone is 140-145°C, the temperature of the second zone is 160-165°C, the temperature of the third zone is 175-180°C, the temperature of the fourth zone is 190-200°C, and the temperature of the fifth zone is 190-200°C. The temperature of the zone is 205-210℃, and the temperature of the sixth zone is 220-225℃; the main engine speed of the twin-screw extruder is 250-300r / min, and the current ...

Embodiment 3

[0056] A preparation method of an anti-ant protective layer, comprising the following contents:

[0057] 1) Weigh each component according to the formula of the protective layer, add it to the mixer and mix, and release the material after mixing;

[0058] 2) Add the mixed material in step 1) into the twin-screw extruder for melt blending, and after the material comes out of the die in the twin-screw extruder, the protective layer is obtained by blow molding, which is recorded as the sample 3. The temperature of each zone of the twin-screw extruder is set as follows: the temperature of the first zone is 140-145°C, the temperature of the second zone is 160-165°C, the temperature of the third zone is 175-180°C, the temperature of the fourth zone is 190-200°C, and the temperature of the fifth zone is 190-200°C. The temperature of the zone is 205-210℃, and the temperature of the sixth zone is 220-225℃; the main engine speed of the twin-screw extruder is 250-300r / min, and the curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com