Method for changing reversal domain width of potassium titanyl phosphate crystal material

A technology of potassium titanyl phosphate and crystal materials, which is applied in the directions of polycrystalline material growth, crystal growth, chemical instruments and methods, etc., can solve the problems affecting the optical conversion efficiency of periodically polarized crystals, excessive domain wall broadening, etc. The effect of optical conversion efficiency, improved quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The present embodiment discloses a method for changing the inversion domain width of potassium titanyl phosphate crystal material, comprising the following steps:

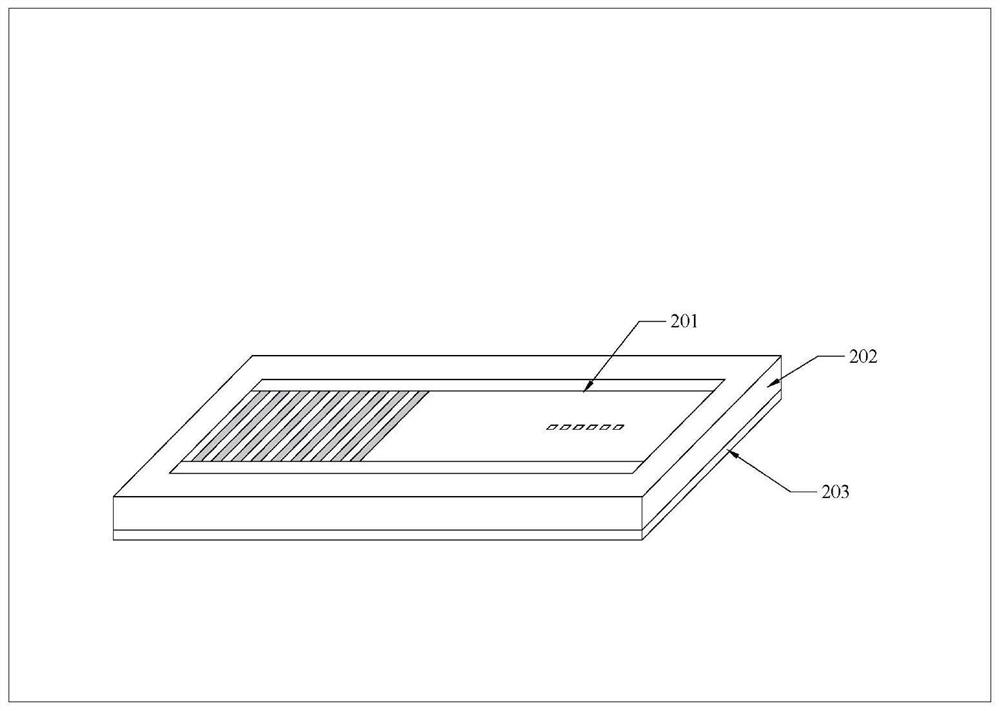

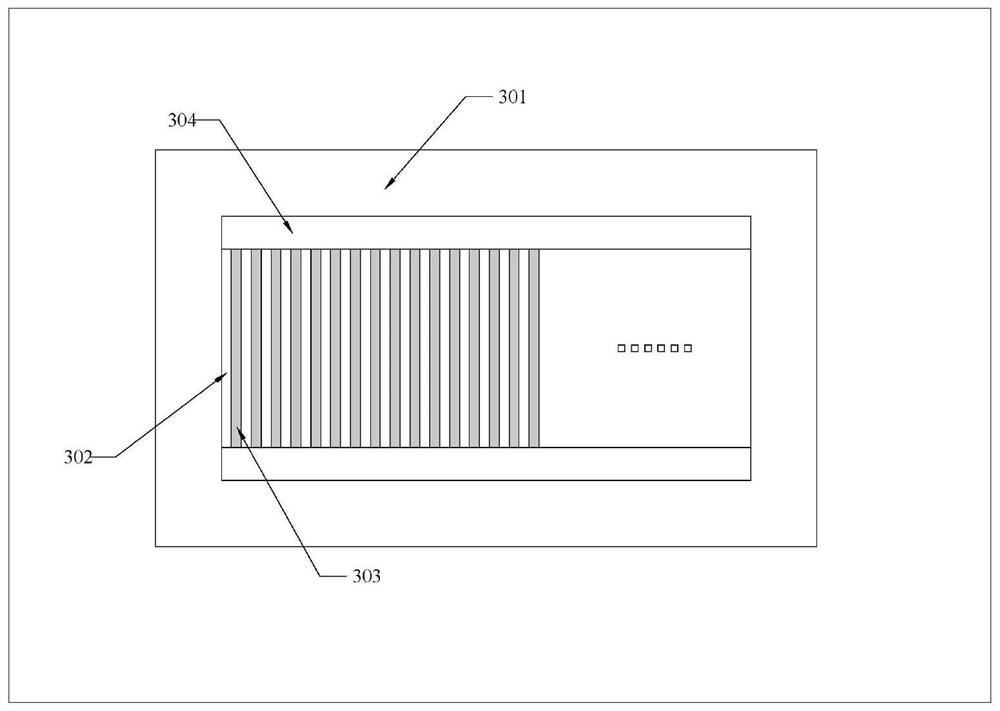

[0052] (1) respectively making the first electrode and the second electrode on the -Z plane and the +Z plane of the potassium titanyl phosphate crystal substrate;

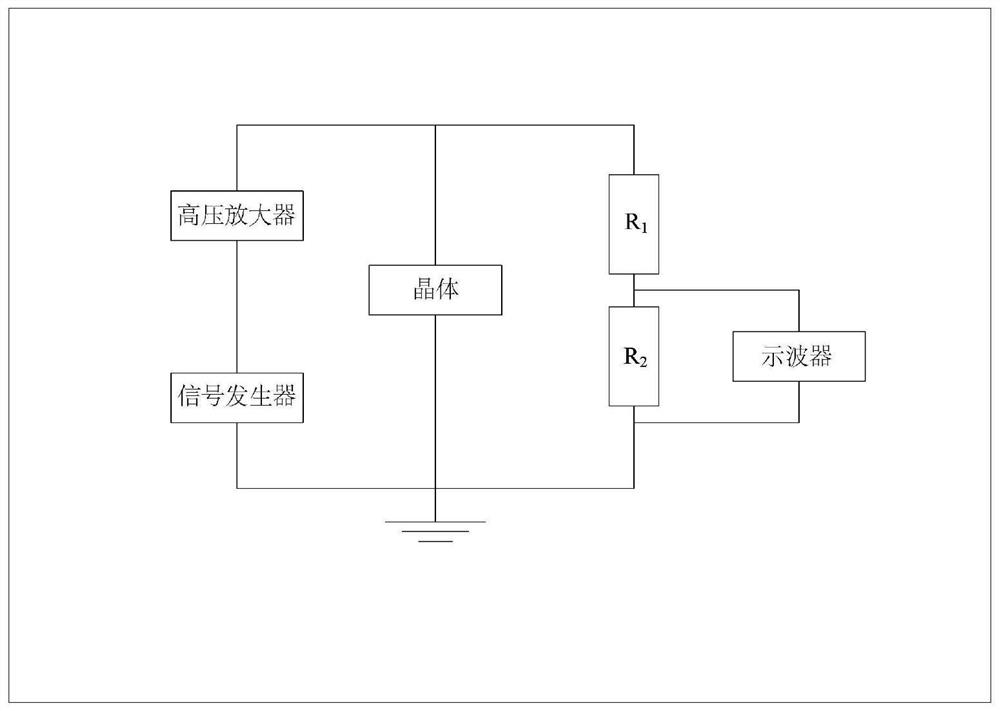

[0053] (2) Periodically polarize the above-mentioned potassium titanate phosphate crystals that have been prepared by applying a pulse voltage, and set the polarization parameters of the electrode wire group according to the size of the first electrode, with the help of the electrode structure of the present invention, and by figure 1 The schematic diagram of the polarization device shown controls the polarization conditions of the electrode wire group between the first electrode 201 and the second electrode 203 to realize the potassium titanyl phosphate crystal material between the first electrode 201 and the second electrode 203 The polarizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com