Epitaxial structure of light emitting diode and preparation method thereof

A technology of light-emitting diodes and epitaxial structures, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reduced light-emitting diode luminous efficiency, high defect density and polarization effect, large lattice mismatch and thermal mismatch, etc. Achieve the effect of improving electron-hole recombination efficiency, preventing non-radiative recombination, and reducing the difference in electron-hole concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

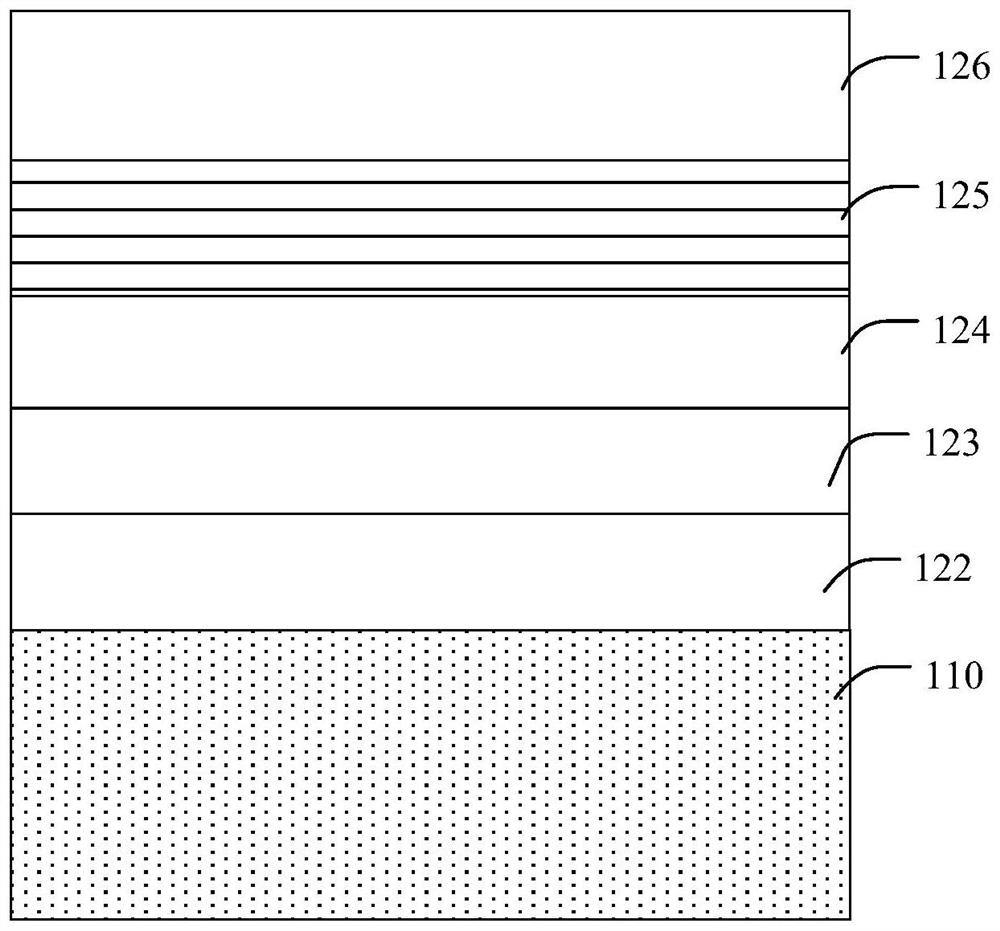

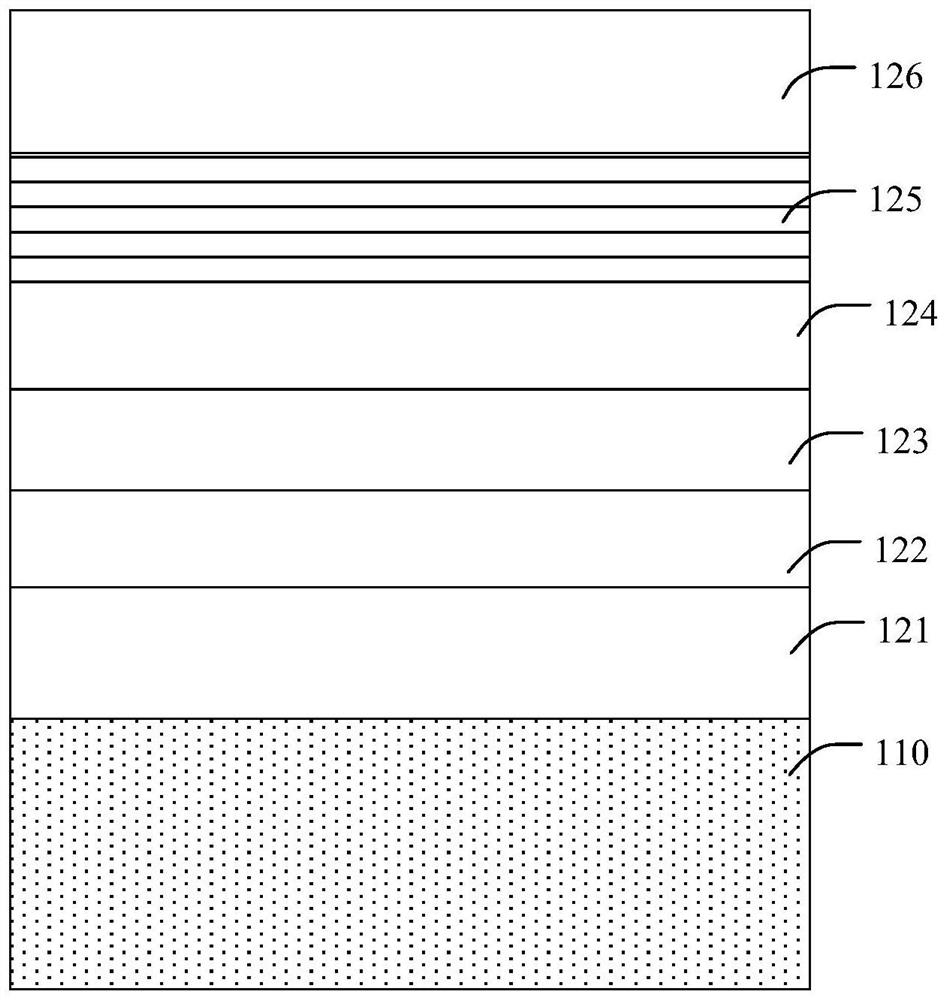

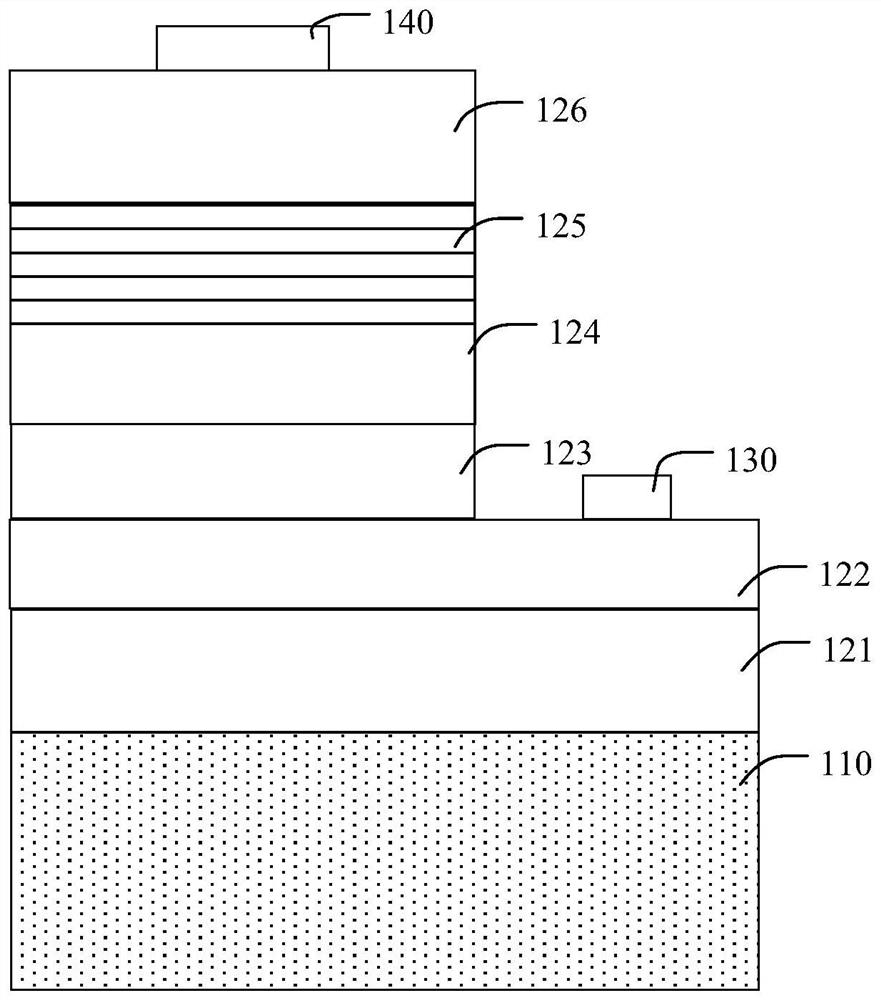

[0045] The present invention will be described in more detail below with reference to the accompanying drawings. In the various figures, identical components are designated by similar reference numerals. For the sake of clarity, various parts in the figures have not been drawn to scale. Additionally, some well-known parts may not be shown.

[0046] The invention may be embodied in various forms, some examples of which will be described below.

[0047] In the prior art, due to the lattice mismatch and thermal mismatch between the substrate and the epitaxial layer, the epitaxial layer produces a higher defect density and polarization reaction, thereby producing non-radiative recombination and spatial separation of the electron wave function, and further. Reduce the luminous efficiency of light-emitting diodes. Specifically, since the hole ionization efficiency of the epitaxial layer is much lower than the electron ionization efficiency, the hole concentration is 1 to 2 orders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com