Wet desulphurization spherical tower, application thereof and wet desulphurization process

A wet desulfurization and spherical technology, which is applied in the field of wet desulfurization process and wet desulfurization spherical tower, can solve the problems of increased floor space, increased cost, increased maintenance cost, increased investment cost, and large occupied space. Achieve the effect of reducing equipment investment, small footprint and space, and large internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

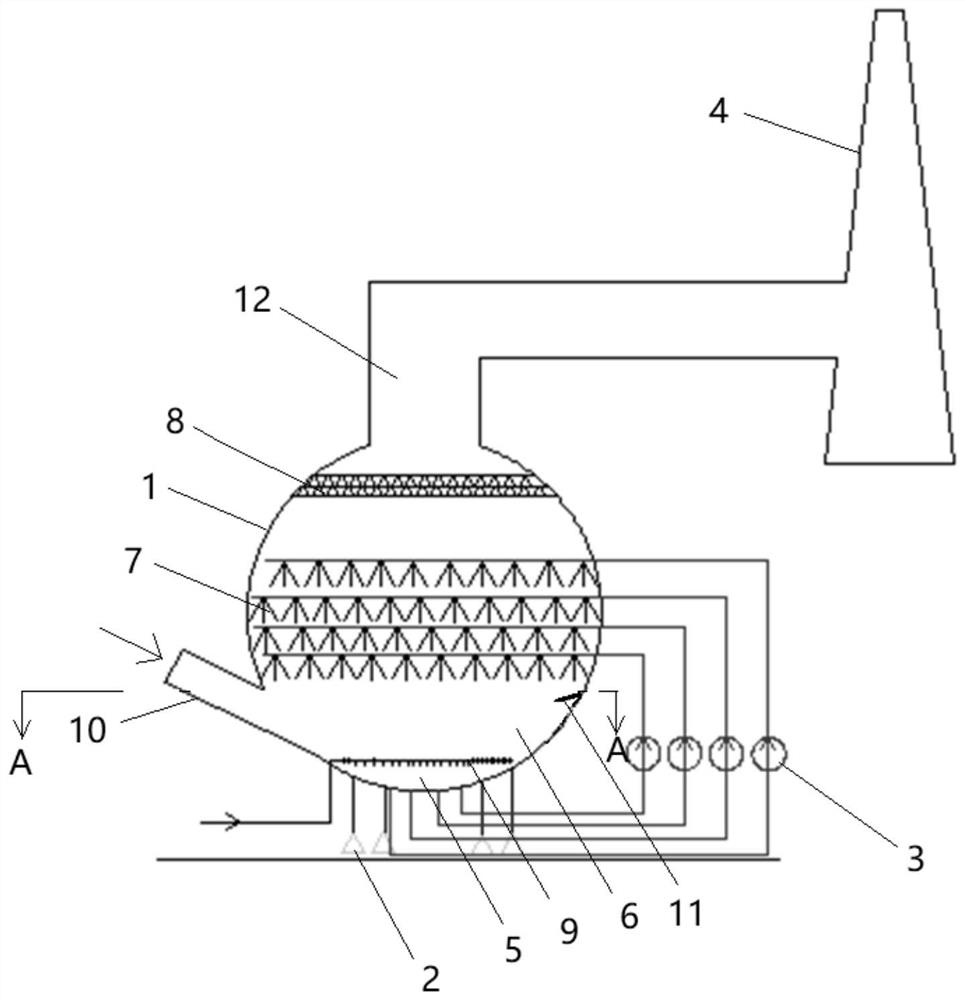

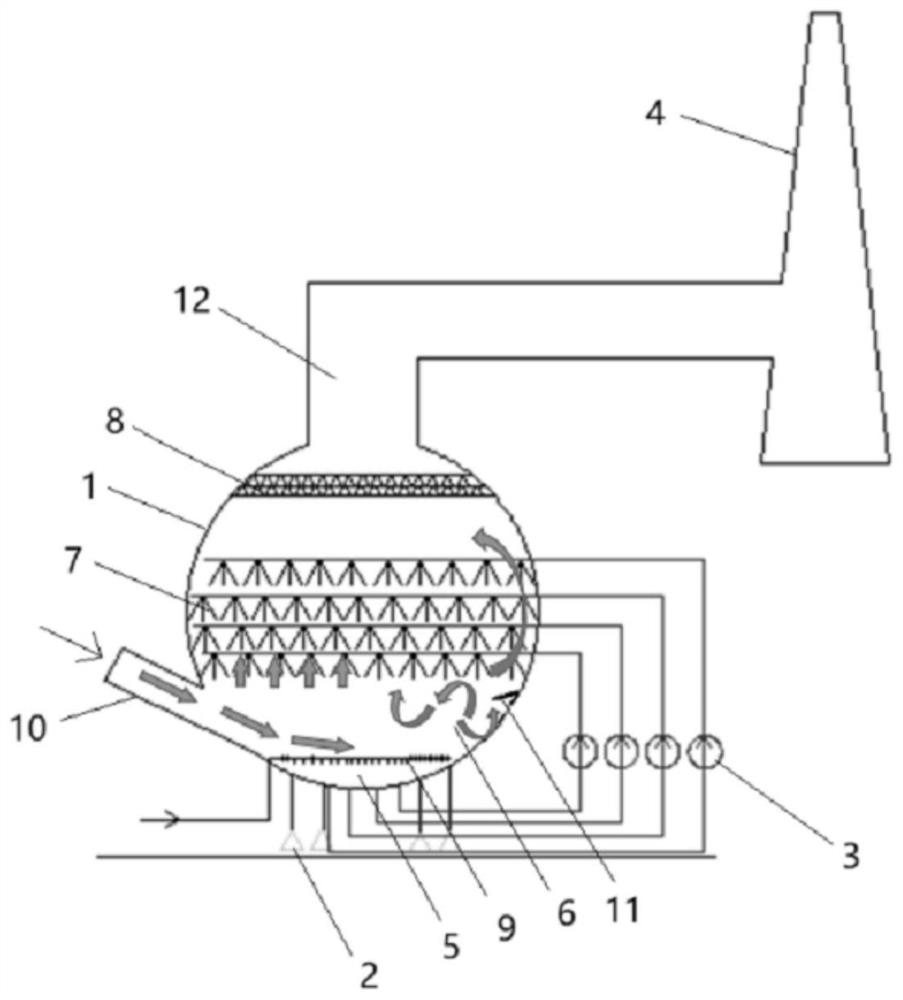

[0098] When using the wet desulfurization spherical tower of the present invention to perform desulfurization treatment on 600,000 cubic meters of flue gas, in order to obtain a sulfur dioxide content lower than 35 mg / Nm 3 , the droplet volume is less than 40mg / m 3 The clean flue gas, the wet desulfurization spherical tower, such as Figure 1-2 shown:

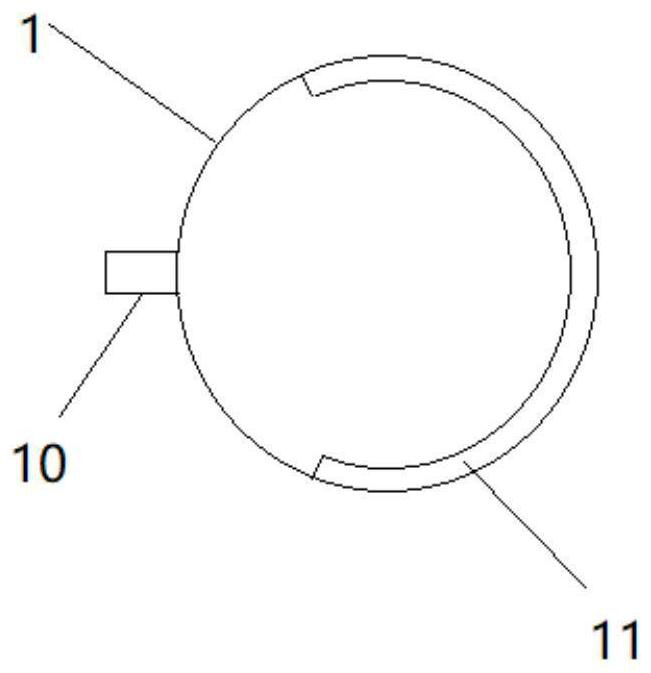

[0099] The diameter of the spherical tower body 1 is 15m; the spray layer has 4 layers, and the nozzles include a first nozzle and a second nozzle, the first nozzle is adjacent to the inner wall of the spherical tower body 1, and the The second nozzle is not adjacent to the inner wall of the spherical tower body 1; the spray angle of the first nozzle is 90°, and the spray angle of the second nozzle is 120°; the defogging layer 8 further includes The packing plate layer is located below the mist eliminator layer; the mist eliminator is a roof ridge mist eliminator; the slurry circulating pump 3 has four sets, and its suction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com