Editable dynamic phosphorescent flexible film and application method thereof

A technology of flexible film and phosphorescence effect, which is applied in chemical instruments and methods, luminescent materials, synthetic resin layered products, etc., and can solve problems such as inability to edit grayscale images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 1 g of PVP with a molecular weight of 58,000, dissolve it in 40 mL of double-distilled water with stirring, heat it to 50 degrees Celsius, and add ethanol in which 1 mg of Molecular A is dissolved at one time, and continue to heat and stir at 65 degrees. Among them, the molecular formula of molecule A is as follows:

[0043]

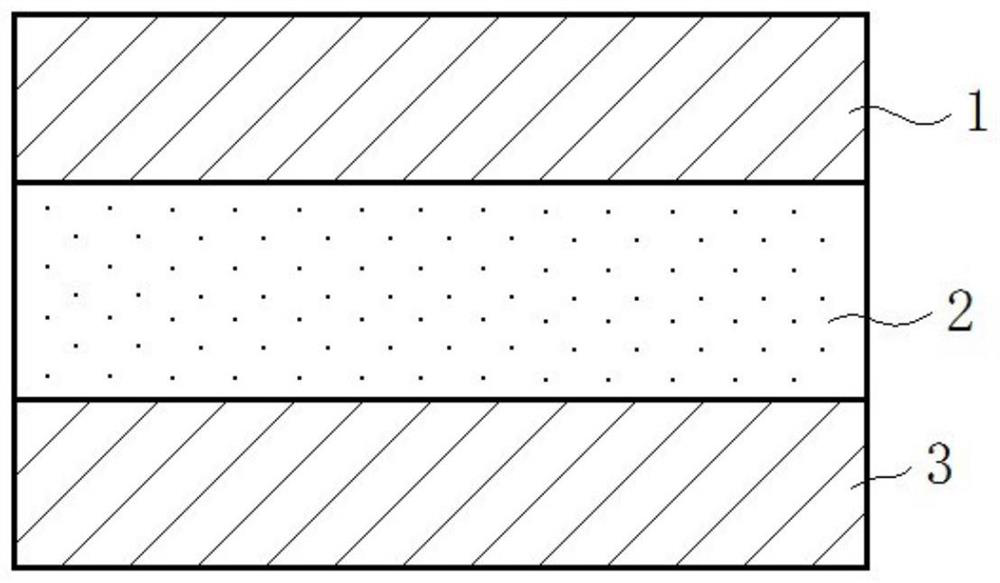

[0044] All the above solutions were transferred to a 20cm×20cm square flat-bottomed polystyrene petri dish, heated on a 30°C hot plate overnight to remove most of the solvent to obtain a functional layer film (thickness 50μm). It was transferred to a 120°C vacuum oven to be heated and dried for 2 hours, and then taken out and plastic-sealed with a 50 μm PET (polyethylene terephthalate, polyethylene terephthalate) film to obtain an editable dynamic phosphorescence flexible film 1 .

Embodiment 2

[0046] Weigh 1 g of PVP with a molecular weight of 360,000, dissolve it in 40 mL of double-distilled water with stirring, add ethanol in which 20 mg of molecular B is dissolved at one time after heating to 50 degrees Celsius, and continue to heat and stir at 65 degrees to evenly evaporate the ethanol. Among them, the molecular formula of molecule B is as follows:

[0047]

[0048] All the above solutions were transferred to a 20cm×20cm square flat-bottomed polystyrene petri dish, heated on a 30°C hot plate overnight to remove most of the solvent to obtain a functional layer film (thickness 50μm). It was transferred to a vacuum oven at 120 °C for heating and drying for 2 h, and then plastic-sealed with a 50 μm PET film to obtain an editable dynamic phosphorescent flexible film 2 .

Embodiment 3

[0050] Weigh 1 g of 1.3 million molecular weight PVP, dissolve it in 40 mL of double-distilled water with stirring, add ethanol in which 20 mg of molecular C is dissolved at one time after heating to 50 degrees Celsius, and continue to heat and stir at 65 degrees to evaporate the ethanol. Among them, the molecular formula of molecule C is as follows:

[0051]

[0052] All the above solutions were transferred to a 20cm×20cm square flat-bottomed polystyrene petri dish, heated on a 30°C hot plate overnight to remove most of the solvent to obtain a functional layer film (thickness 50μm). It was transferred to a 120°C vacuum oven for heating and drying for 2 hours, and then plastic-sealed with a 50 μm PET film to obtain an editable dynamic phosphorescent flexible film 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap