Method for purifying recombinant mussel-like mucin

A technique for mussel mucin and a purification method, which is applied in the field of purification of recombinant mussel mucin, and can solve the problems of low purification yield, low content and high endotoxin content of the recombinant mussel mucin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

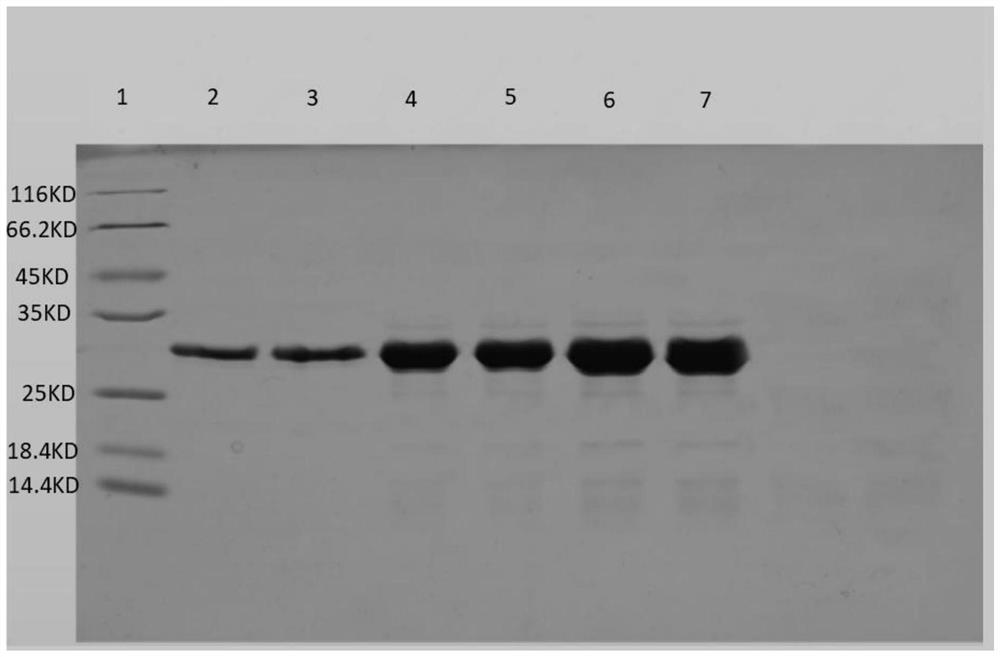

Image

Examples

Embodiment 1

[0038] 1) After the fermentation in the fermenter, the volume of the fermented liquid is 60 L, 12000 g of lactose and 600 mL of Triton X-100 are added to the fermented liquid, and the stirring is continued at 200 rpm for 1 h.

[0039] 2) discharge the feed liquid, centrifuge at 4000rpm for 15min through a high-speed centrifuge, remove the supernatant and collect the precipitation, the precipitation weighs 8kg, and add 80L of the 10mM citric acid-sodium citrate buffer that contains 1mM EDTA to the precipitation and is pH 6.5, Stir overnight (10 h) at 200 rpm.

[0040] 3) The feed liquid was discharged, centrifuged at 4000rpm for 15min through a high-speed centrifuge, removed the supernatant and collected the precipitation, the precipitation weighed 7kg, and added 56L of the 10mM citric acid-sodium citrate buffer with a pH of 3.7 to the precipitation, and stirred at 200rpm. dissolve.

[0041] 4) Centrifuge the feed liquid at 4000rpm for 15min by a high-speed centrifuge, remove ...

Embodiment 2

[0049] 1) After the fermentation in the fermenter, the volume of the fermentation broth was 60.5 L, 10000 g of lactose and 1200 mL of SDS were added to the fermentation broth, and the stirring was continued at 200 rpm for 1 h.

[0050] 2) The feed liquid was discharged, centrifuged at 4000rpm for 15min through a high-speed centrifuge, the supernatant was removed to collect the precipitate, the precipitate weighed 8.4kg, and 96L of 10mM citric acid-sodium citrate buffer containing 1.5mM EDTA with a pH of 6.5 was added to the precipitate. The solution was stirred at 200 rpm overnight (10 h).

[0051] 3) The feed liquid was discharged, centrifuged at 4000rpm for 15min through a high-speed centrifuge, the supernatant was removed to collect the precipitate, the precipitate weighed 7.2kg, and 72L of pH was added to the precipitate. In the 10mM citric acid-sodium citrate buffer, 200rpm Stir to dissolve.

[0052] 4) Centrifuge the feed liquid at 4000rpm for 15min through a high-speed...

Embodiment 3

[0060] 1) After the fermentation in the fermenter, the volume of the fermented liquid is 59 L, 9000 g of lactose and 600 mL of Triton X-100 are added to the fermented liquid, and the stirring is continued at 200 rpm for 1 h.

[0061] 2) The feed liquid was discharged, centrifuged at 4000rpm for 15min through a high-speed centrifuge, the supernatant was removed to collect the precipitate, the precipitate weighed 8.1kg, and 90L of 10mM citric acid-sodium citrate buffer containing 1mM EDTA at pH 6.5 was added to the precipitate. , stirred at 200 rpm overnight (10 h).

[0062] 3) The feed liquid was discharged, centrifuged at 4000rpm for 15min through a high-speed centrifuge, removed the supernatant and collected the precipitation, the precipitation weighed 6.8kg, and added 36L of the 10mM citric acid-sodium citrate buffer with a pH of 3.7 to the precipitation. Stir to dissolve.

[0063] 4) The feed liquid was centrifuged at 4000rpm for 15min through a high-speed centrifuge, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com