Self-mixing floating microalgae reactor control method

A control method, reactor technology, applied in the directions of microorganism-based methods, bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, etc., can solve the problems of insufficient mixing, unstable wave energy, oxygen transfer Problems such as small prime coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

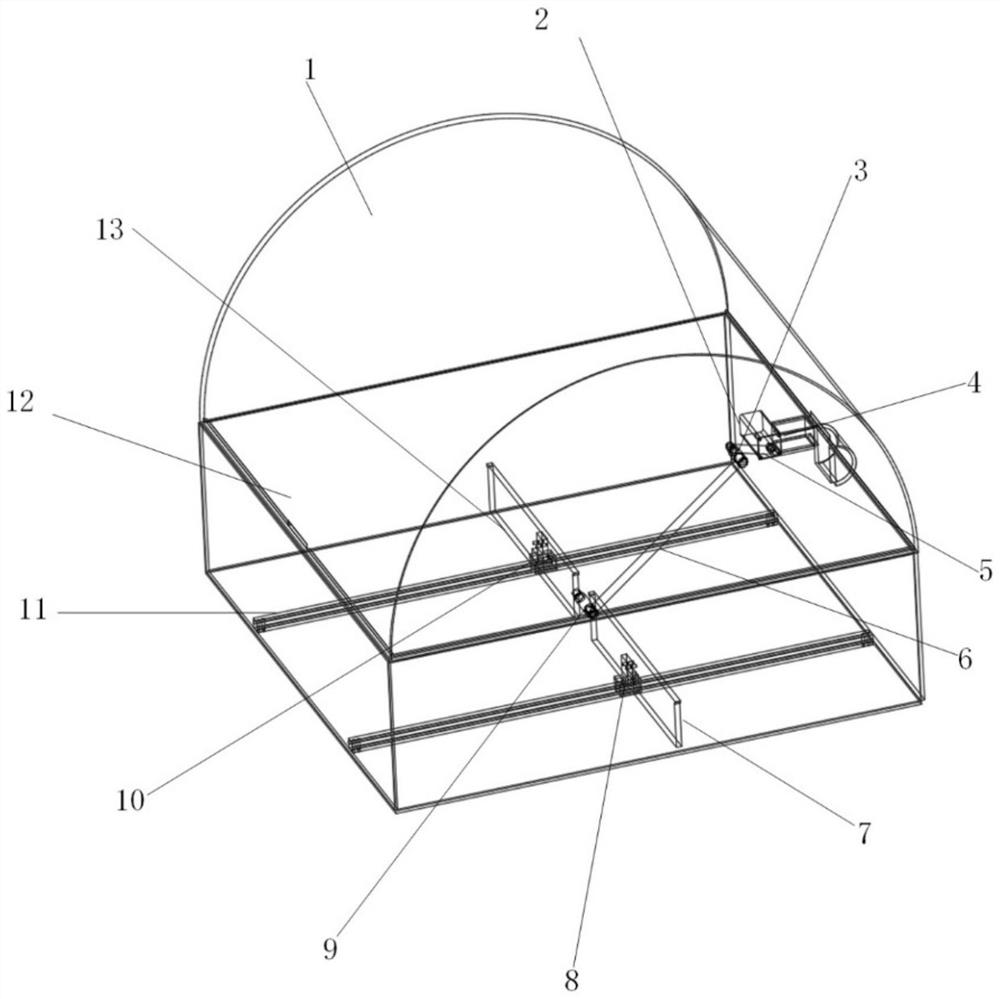

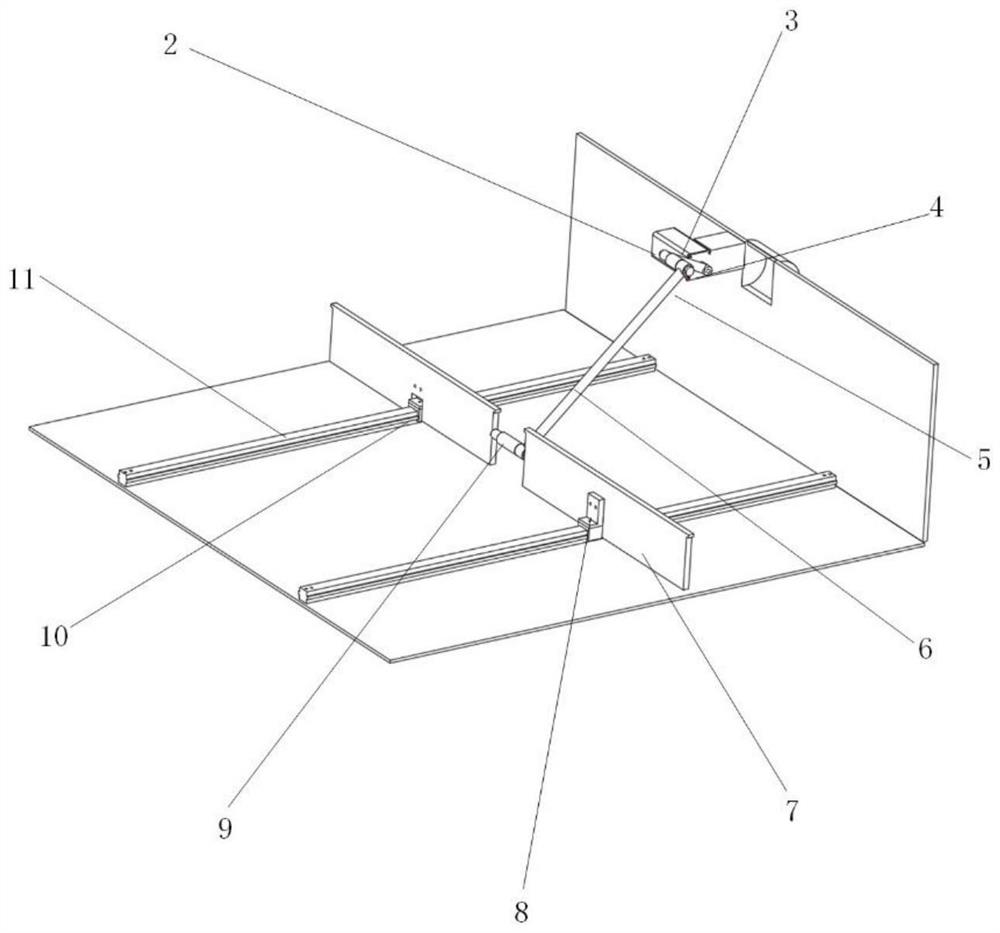

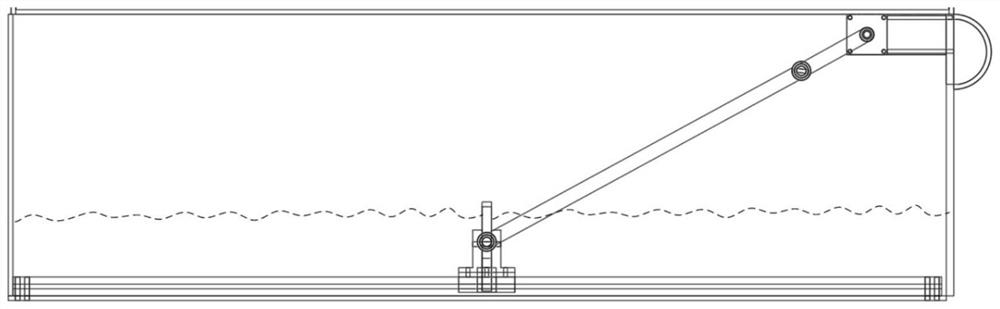

[0044] like Figure 1-3 As shown, this embodiment provides a self-mixing floating microalgae reactor, including: a reactor box 12, which has a accommodating space. This embodiment does not limit the shape of the accommodating space, which can be changed according to actual reaction needs. setting, the culture medium is stored in the accommodating space; the driving unit is a power output device, and the driving unit is at least partially installed in the reactor box 12; the wave making unit, which is connected with the driving unit and is driven by the driving unit, can be The accommodating space of the reactor box 12 periodically reciprocates and forms a horizontal artificial surge in the culture solution.

[0045] Compared with the prior art, a wave-making unit is installed in this embodiment to form an artificial surge. When the natural wave energy is unstable and the mixing is insufficient, an artificial surge can be added, thereby effectively improving the mixing performa...

Embodiment 2

[0047]In addition to the technical contents described in the foregoing embodiments, this embodiment further defines the drive unit, which further includes: a drive motor 2 . A feasible installation method is that the drive motor 2 is installed on the reactor box through the motor base 4 12 The inner wall surface; also includes a crank-slider mechanism, which refers to a plane connecting rod mechanism that uses a crank and a slider to realize the mutual conversion of rotation and movement. In the crank-slider mechanism, the component that forms the moving pair with the frame is the slider, and the component that connects the crank and the slider through the rotating pair is the connecting rod. In this embodiment, the crank 5 is connected to the drive motor 2, and the slider 10 is connected to the The wave units are connected and can reciprocate periodically on the slide rail 11 , and the slide rail 11 is fixed on the bottom of the reactor box 12 .

[0048] In addition, it shoul...

Embodiment 3

[0050] In addition to the technical contents described in the foregoing embodiments, this embodiment further defines the crank-slider mechanism, which further includes: a first coupling 3 that rotatably connects the rocker 6 and the crank 5 The second coupling 9, the second coupling 9 rotatably connects the rocker 6 with the wave-making unit, and through the first coupling 3 and the second coupling 9, the output shaft of the drive motor 2 rotates in the first The second coupling 9 is converted into the reciprocating linear motion of the wave-making unit along the horizontal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com