Catalyst for TPX polymer as well as preparation method and application of catalyst

A catalyst and polymer technology, applied in the field of TPX polymer catalyst and its preparation, can solve the problem of low catalyst activity, achieve the effects of improving catalyst activity, reducing dosage, and improving steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

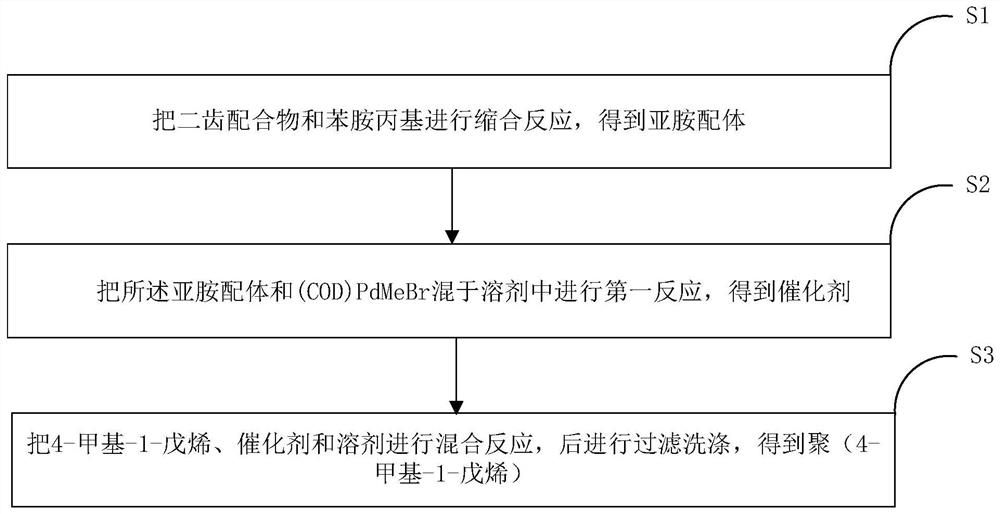

[0045] According to another typical embodiment of the present invention, there is provided a preparation method of the above-mentioned TPX polymer catalyst, the method comprising:

[0046] S1. The bidentate complex and the aniline propyl group are subjected to a condensation reaction to obtain an imine ligand;

[0047] Specifically, in this embodiment, the reaction flask is baked at high temperature to remove the water vapor in the reaction flask, then the reaction flask is filled with nitrogen, and the reaction is carried out in an oxygen-free environment, an appropriate amount of bidentate complex is added to the reaction flask, and simultaneously Appropriate amount of aluminum chloride, then an appropriate amount of aniline propyl group and bidentate complex are added for condensation reaction to obtain imine ligand.

[0048] Wherein, the molar ratio of bidentate complex:anilinopropyl:aluminum chloride is 1:1:3, and the reaction time of the condensation reaction is 10-15 ho...

Embodiment 1

[0073] A preparation method of poly(4-methyl-1-pentene), the method comprises:

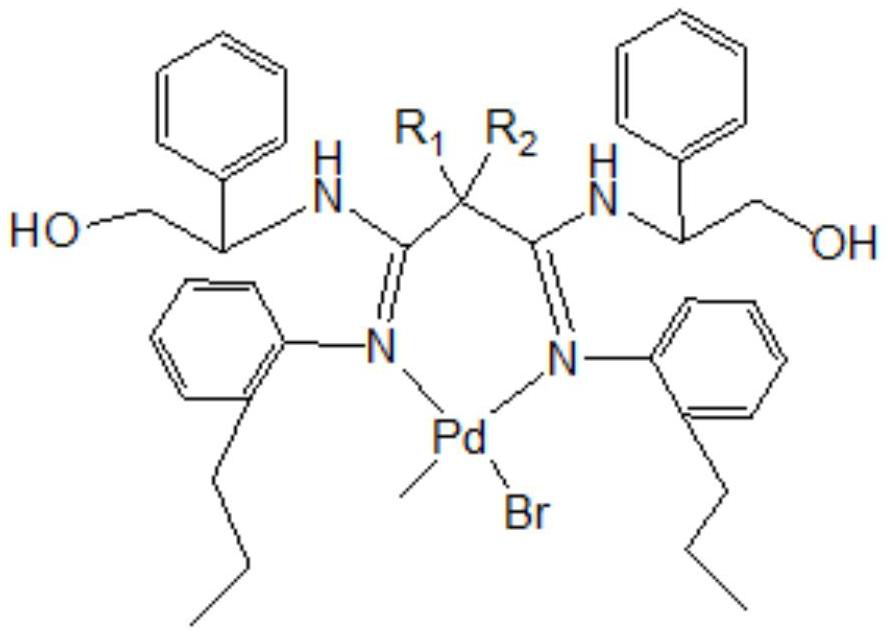

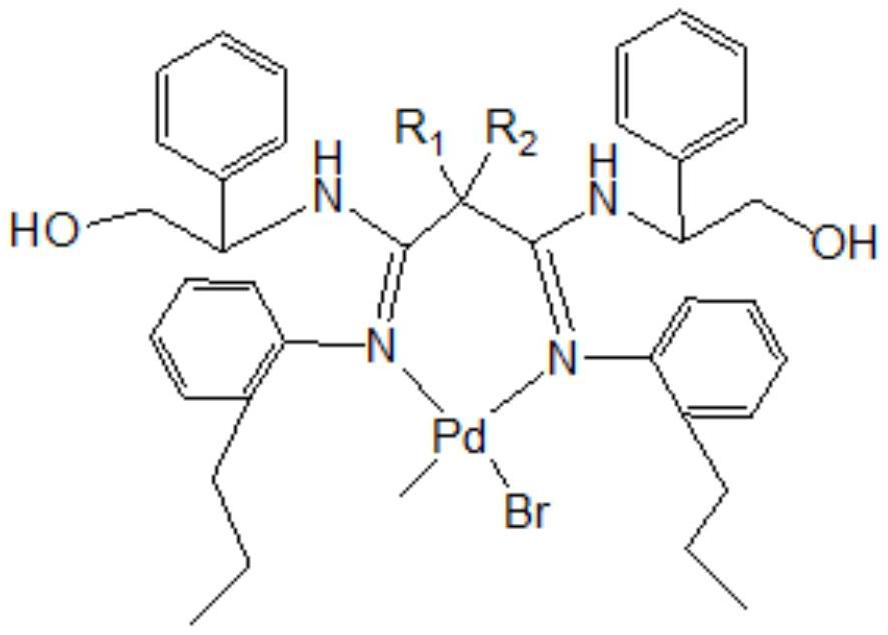

[0074] 1. Synthesis of catalyst

[0075] Bake the reaction flask at high temperature to remove the water vapor in the reaction flask, then fill the reaction flask with nitrogen, and in an oxygen-free environment, add 12 mmol of propylaniline to the reaction flask, and at the same time, add 12 mL of aluminum chloride to the reaction flask, and the temperature is set to 135 ° C, the reaction was carried out for 3 h, then the temperature was reduced to 25 ° C, and 12 mmol of bidentate complex and propylaniline were added to carry out the condensation reaction. The 0.5mmol diimine compound obtained by the condensation reaction, 0.5mmol diimine compound and 0.6mmol (COD) PdMeBr were added to the reaction flask under nitrogen atmosphere, and the solvent 20ml dichloromethane was added to the reaction flask, and the reaction was carried out at room temperature. 12h, then the solvent was evaporated with a...

Embodiment 2

[0079] A preparation method of poly(4-methyl-1-pentene), the method comprises:

[0080] 1. Synthesis of catalyst

[0081] Bake the reaction flask at high temperature to remove the water vapor in the reaction flask, then fill the reaction flask with nitrogen, add 10 mmol of propylaniline to the reaction flask in an oxygen-free environment, and add 30 mL of aluminum chloride to the reaction flask at the same time, and set the temperature to 120 ° C, the reaction was carried out for 3 h, and then the temperature was reduced to 25 ° C, and 10 mmol of bidentate complex and propylaniline were added to carry out the condensation reaction. The 0.4 mmol diimine ligand obtained by the condensation reaction, under nitrogen atmosphere, 0.4 mmol imine compound and 0.5 mmol (COD) PdMeBr were added to the reaction flask, and 20 ml of dichloromethane solvent was added to the reaction flask, and the reaction was carried out in the reaction flask. The reaction was carried out at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com