Rubber composition and preparation method thereof

A technology of rubber composition and masterbatch, which is applied in the field of rubber, can solve the problems such as not easy to disperse, and achieve the effect of good wear, high tensile strength and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

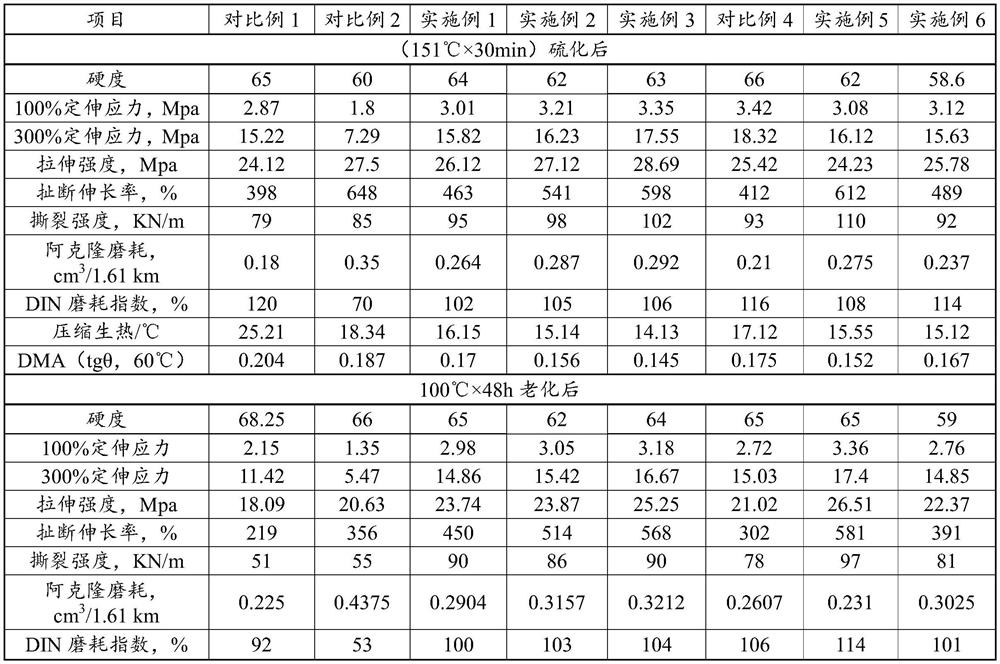

Examples

Embodiment 1

[0050] This embodiment provides a hydroxy POSS / natural rubber composition for regulating the physicochemical properties of the sizing material and a preparation method thereof.

[0051] The formula is specifically:

[0052] In parts by weight, it includes the following components: 100 parts of natural rubber, 2 parts of D-POSS, 5 parts of silane coupling agent, 40 parts of high wear-resistant carbon black (HAF) N330, 8 parts of zinc oxide, 2.5 parts of stearic acid parts, 2.5 parts of antioxidant, 3 parts of S, and 1 part of accelerator; among them, granule glue 1# is used, the molecular weight is 300,000-350,000, the low viscosity system is used, the Mooney viscosity is 68 degrees, and 1,4- The isoprene unit accounts for 90% of the mass of the rubber segment of the pellet rubber.

[0053] The preparation method includes the following steps:

[0054] The first stage of mixing: the rotor speed is 45rpm, and the upper bolt pressure is 6.0MPa. First, the hydroxyl POSS and silan...

Embodiment 2

[0058] This embodiment provides a hydroxy POSS / natural rubber composition for regulating the physicochemical properties of the sizing material and a preparation method thereof.

[0059] The formula is specifically:

[0060] In parts by weight, it includes the following components: 100 parts of natural rubber, 2.2 parts of D-POSS, 5 parts of silane coupling agent, 40 parts of high wear-resistant carbon black (HAF) N330, 8 parts of zinc oxide, 2.5 parts of stearic acid parts, 2.5 parts of antioxidant, 3 parts of S, and 1 part of accelerator.

[0061] The preparation method is the same as in Example 1.

Embodiment 3

[0063] This embodiment provides a hydroxy POSS / natural rubber composition for regulating the physicochemical properties of the sizing material and a preparation method thereof.

[0064] The formula is specifically:

[0065] In parts by weight, it includes the following components: 100 parts of natural rubber, 3 parts of D-POSS, 5 parts of silane coupling agent, 40 parts of high wear-resistant carbon black (HAF) N330, 8 parts of zinc oxide, 2.5 parts of stearic acid parts, 2.5 parts of antioxidant, 3 parts of S, and 1 part of accelerator.

[0066] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mooney viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com