Liquid hydrogen conveying pipeline

A technology for transporting pipelines and liquid hydrogen, which is applied in pipeline protection, pipeline heating/cooling, and pipeline protection through thermal insulation, etc. It can solve problems such as aggravating hydrogen energy loss, achieve uniform force, reduce thermal energy loss, and reduce contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

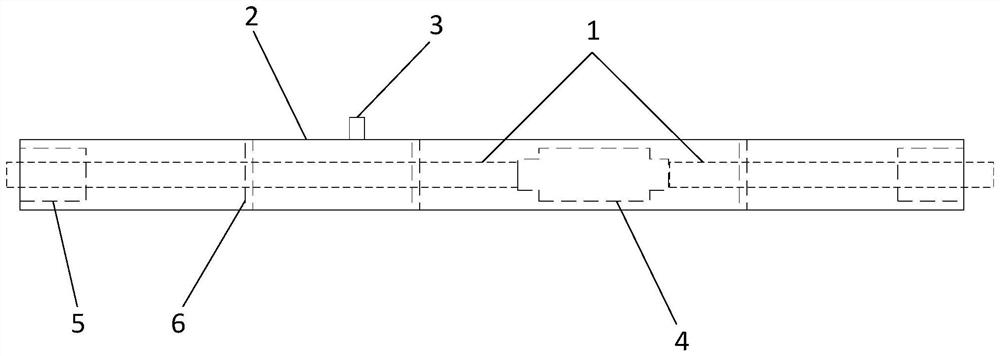

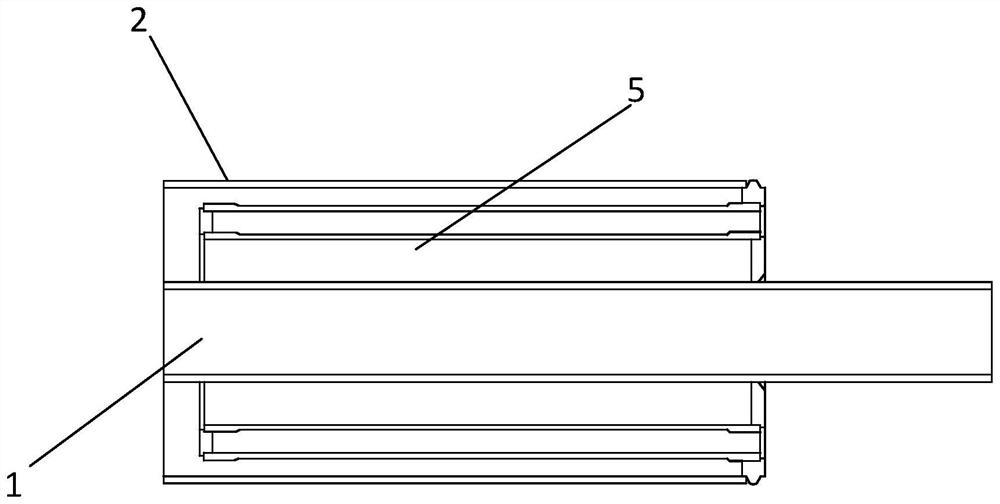

[0036] Embodiment 1 of the present invention provides a liquid hydrogen transport pipeline, such as figure 1 As shown in the figure, it includes at least one conveying pipeline. In this embodiment, the conveying pipeline adopts a double-layer structure, including an inner pipe 1 and an outer pipe 2. The inner pipe 1 is arranged in the outer pipe 2 and is coaxial with the outer pipe 2. An interlayer space is formed between the inner pipe 1 and the outer pipe 2, and the outer pipe 2 is provided with a vacuum suction port 3 that penetrates the interior of the outer pipe 2, and the air in the interlayer space is evacuated through the vacuum suction port 3, The liquid hydrogen medium is transported in the inner tube 1, the interlayer space is in a vacuum to reduce heat energy transfer, and the outer tube 2 is used to separate the inner space from the atmospheric environment.

[0037] Between the inner pipe 1 and the outer pipe 2, a plurality of thermal insulation support components...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a liquid hydrogen transportation pipeline, and the overall structure of the transportation pipeline is based on the above-mentioned Embodiment 1, and details are not repeated here.

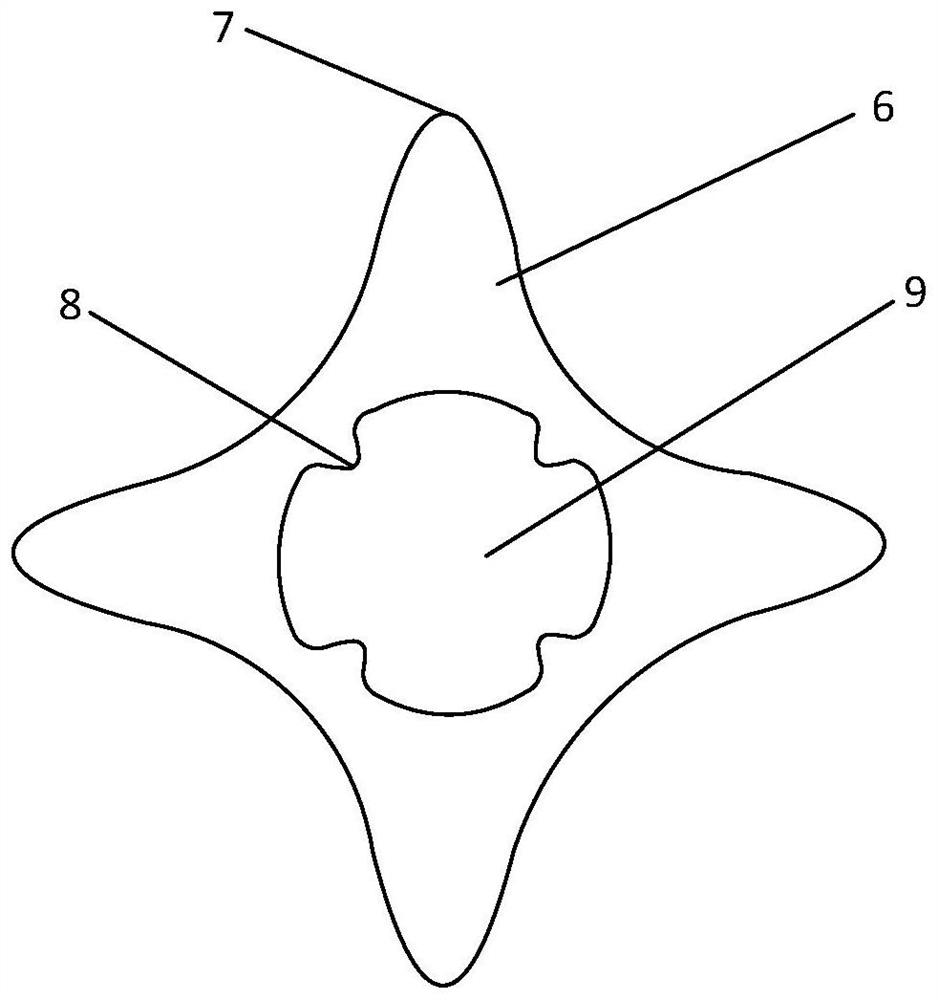

[0050] like figure 2 As shown, in this embodiment, the heat insulating support assembly 6 is provided with a through hole 9 in the middle, through which the through hole 9 is sleeved on the outside of the inner tube 1, and the heat insulating support assembly 6 has a symmetrical structure as a whole. The through hole 9 is sleeved on the outer side of the inner pipe 1 to realize the support, so that the force is uniform everywhere in the pipe, and the uneven weight distribution of the thermal insulation support assembly 6 itself is avoided to affect the force in the conveying pipeline;

[0051] The adiabatic support assembly includes a number of symmetrical fulcrums 7, which are supported between the inner tube 1 and the outer tube 2 through th...

Embodiment 3

[0056] Embodiment 3 of the present invention provides a liquid hydrogen transportation pipeline, and the overall structure of the transportation pipeline is based on the above-mentioned Embodiment 1 or 2, and details are not repeated here.

[0057] In this embodiment, there is also a fixing member on the thermal insulation support assembly 6, and the fixing member includes a mounting portion 10 and a fixing portion 11, and the mounting portion 10 is provided in the concave structure of the connecting portion between the fulcrums When fixing, the fixing portion 11 is on either side of the two sides of the heat insulating support assembly 6 , and the fixing portion 11 and the inner tube 1 are clamped to the outside of the inner tube 1 in the same direction.

[0058] The fixing portion 11 is adapted to the shape and structure of the outer side of the inner tube 1, so as to better fit the outer side of the inner tube.

[0059] Specifically, in this embodiment, the fixing portion 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap