Steam pressure prediction method and device based on LSTM deep recurrent neural network

A technology of cyclic neural network and prediction method, applied in the field of industrial steam boiler combustion, can solve the problems of large lag of boiler system, achieve strong adaptability, improve automatic control effect, and overcome the effect of high coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

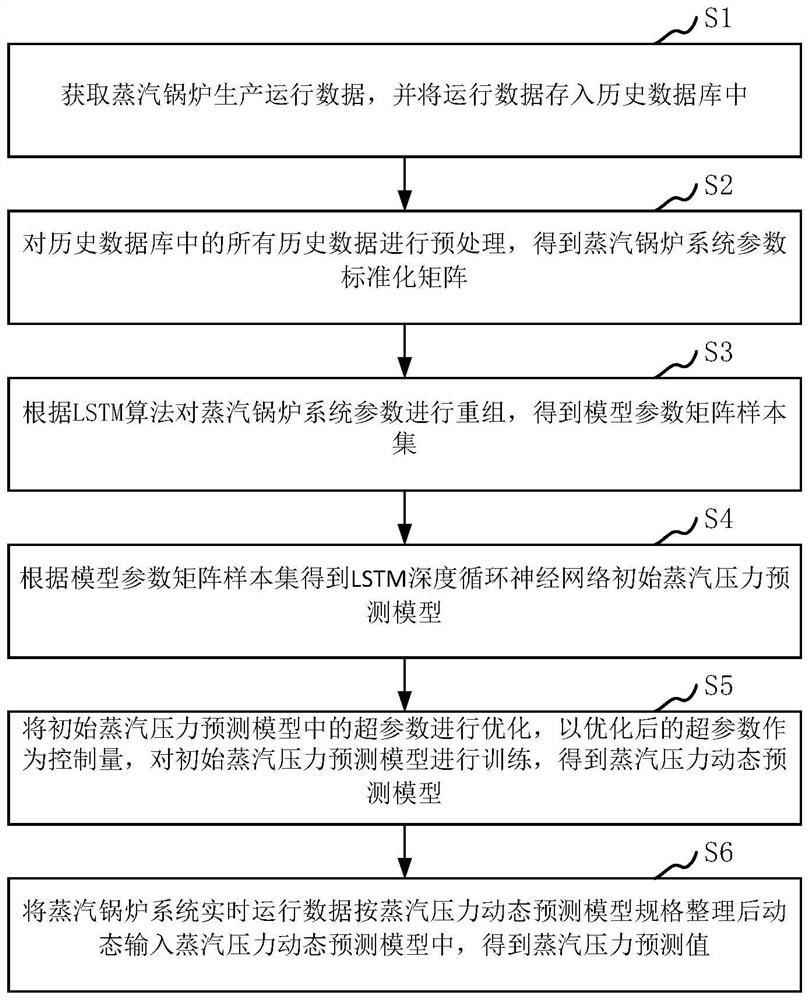

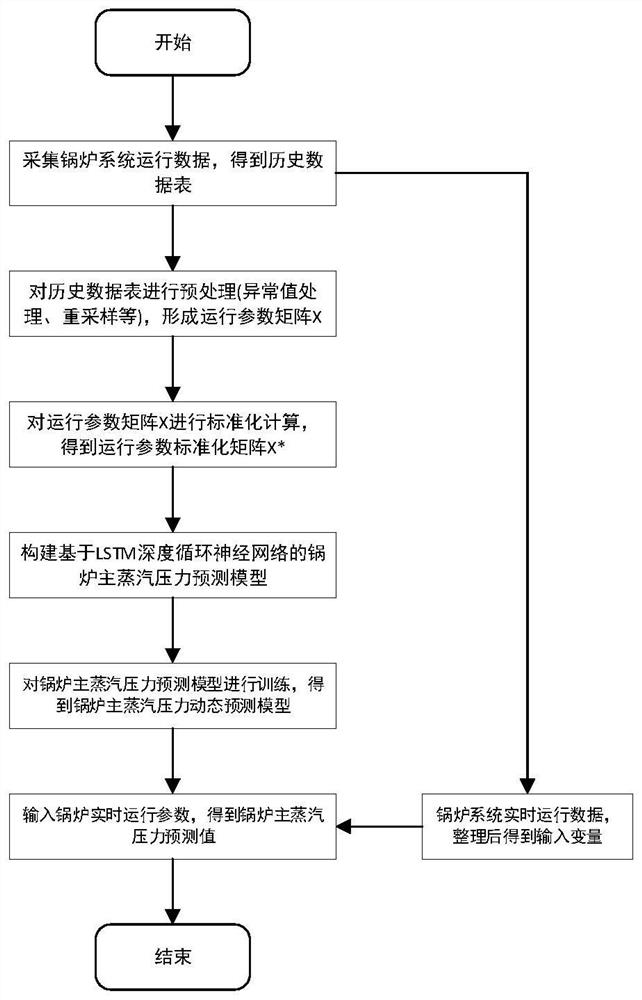

[0049] see figure 1 and figure 2 , this embodiment provides a vapor pressure prediction method based on LSTM deep cyclic neural network, including:

[0050] S1: Obtain the production and operation data of the steam boiler, and store the operation data in the historical database;

[0051] Specifically, according to the input variables of the preset steam boiler steam pressure prediction model, the corresponding steam boiler system operation data is obtained from the DCS system in real time. The collection period of the operation data is 1 second, and the collected operation data includes the furnace negative pressure, furnace temperature, main steam pressure, main steam temperature, pipe network pressure, primary air volume, secondary air volume, boiler load, supply air pressure, soot concentration, flue gas SO2, flue gas NOX, total fuel supply and flue gas content oxygen level, etc.

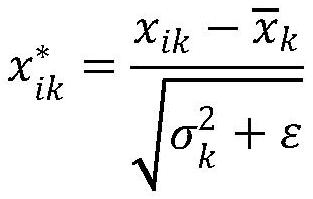

[0052] S2: Preprocess all historical data in the historical database to obtain a standardiz...

Embodiment 2

[0078] This embodiment provides a vapor pressure prediction device based on an LSTM deep cyclic neural network, including:

[0079] The operation data acquisition module is used to acquire the production operation data of the steam boiler, and store the operation data in the historical database;

[0080] a preprocessing module for preprocessing all historical data in the historical database to obtain a standardized matrix of parameters of the steam boiler system;

[0081] The parameter reorganization module reorganizes the parameters of the steam boiler system according to the LSTM algorithm to obtain the model parameter matrix sample set;

[0082] an initial steam pressure prediction model training module, used for obtaining an LSTM deep cyclic neural network initial steam pressure prediction model according to the model parameter matrix sample set;

[0083] The steam pressure dynamic prediction model training module is used to optimize the hyperparameters in the initial ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com