Semiconductor light-emitting device and preparation method and test method thereof

A technology of light-emitting devices and semiconductors, applied to semiconductor lasers, structural details of semiconductor lasers, laser components, etc., can solve problems such as resource waste, cycle thickness deviation, and process cost increase, so as to reduce process costs and resources wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

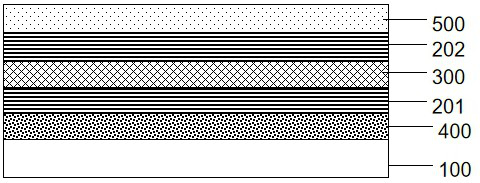

[0036] This embodiment provides a semiconductor light-emitting device, with reference to figure 1 and figure 2 ,include:

[0037] semiconductor substrate layer 100;

[0038] a first Bragg mirror 201 on the semiconductor substrate layer 100;

[0039] an active layer 300 located on the first Bragg mirror away from the semiconductor substrate layer;

[0040] a second Bragg mirror 202 located in the active layer 300 away from the first Bragg mirror 201;

[0041] Both the first Bragg mirror 201 and the second Bragg mirror 202 have bulk atom groups; the first Bragg mirror 201 or the second Bragg mirror 202 has lattice adjustment atoms, and the The diffraction angle corresponding to the diffraction peak of the first Bragg mirror 201 is different from the diffraction angle corresponding to the diffraction peak of the second Bragg mirror 202 , and the lattice adjustment atoms are different from atoms in the bulk atomic group.

[0042] In the semiconductor light emitting device pr...

Embodiment 2

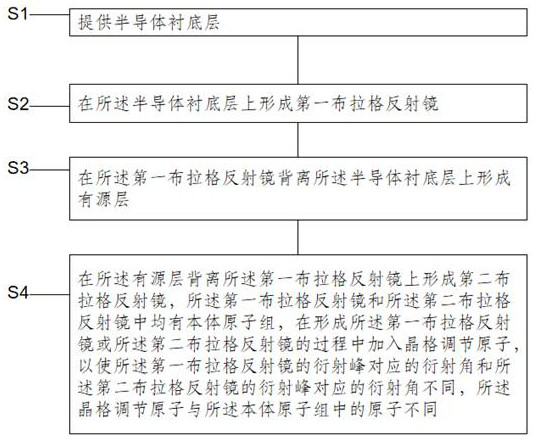

[0064] This embodiment provides a preparation method of a semiconductor light-emitting device, refer to image 3 , including the following steps:

[0065] Step S1: providing a semiconductor substrate layer;

[0066] Step S2: forming a first Bragg mirror on the semiconductor substrate layer;

[0067] Step S3: forming an active layer on the first Bragg mirror facing away from the semiconductor substrate layer;

[0068] Step S4: forming a second Bragg reflector on the active layer away from the first Bragg reflector, the first Bragg reflector and the second Bragg reflector both have bulk atomic groups, and after forming the second Bragg reflector. In the process of the first Bragg mirror or the second Bragg mirror, lattice adjustment atoms are added, so that the diffraction peak of the first Bragg mirror corresponds to the diffraction angle and the diffraction peak of the second Bragg mirror The corresponding diffraction angles are different, and the lattice adjustment atoms a...

Embodiment 3

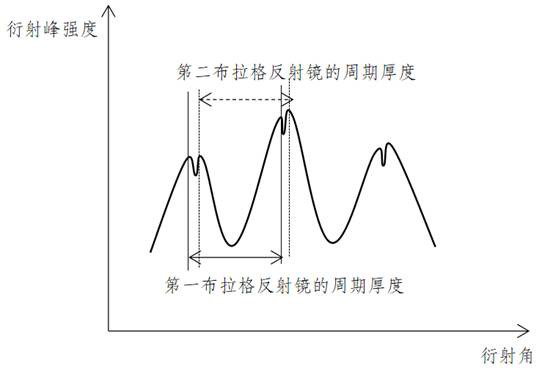

[0100] This embodiment provides a method for testing a semiconductor light-emitting device, including:

[0101] The semiconductor light-emitting device described in Embodiment 1;

[0102] acquiring diffraction spectra of the first Bragg mirror and the second Bragg mirror;

[0103] Obtain the periodic thickness of the first Bragg mirror according to the diffraction angle corresponding to the diffraction peak of the first Bragg mirror in the diffraction spectrum;

[0104] The periodic thickness of the second Bragg mirror is obtained according to the diffraction angle corresponding to the diffraction peak of the second Bragg mirror in the diffraction spectrum.

[0105] In one embodiment, by comparing the periodic thickness of the first Bragg mirror and the periodic thickness of the second Bragg mirror, it is determined whether there is a deviation in the periodic thickness of the first Bragg mirror and the second Bragg mirror, On the basis of the deviation of the periodic thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com