Method for preparing template with macro nanometer sequential holes

A nano-hole and large-size technology, which is applied in the field of preparation of large-size nano-ordered hole templates, can solve the problems of unobtainable and long nano-holes, and achieve the effects of easy depth, low processing cost and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below according to accompanying drawing and embodiment the present invention will be further described:

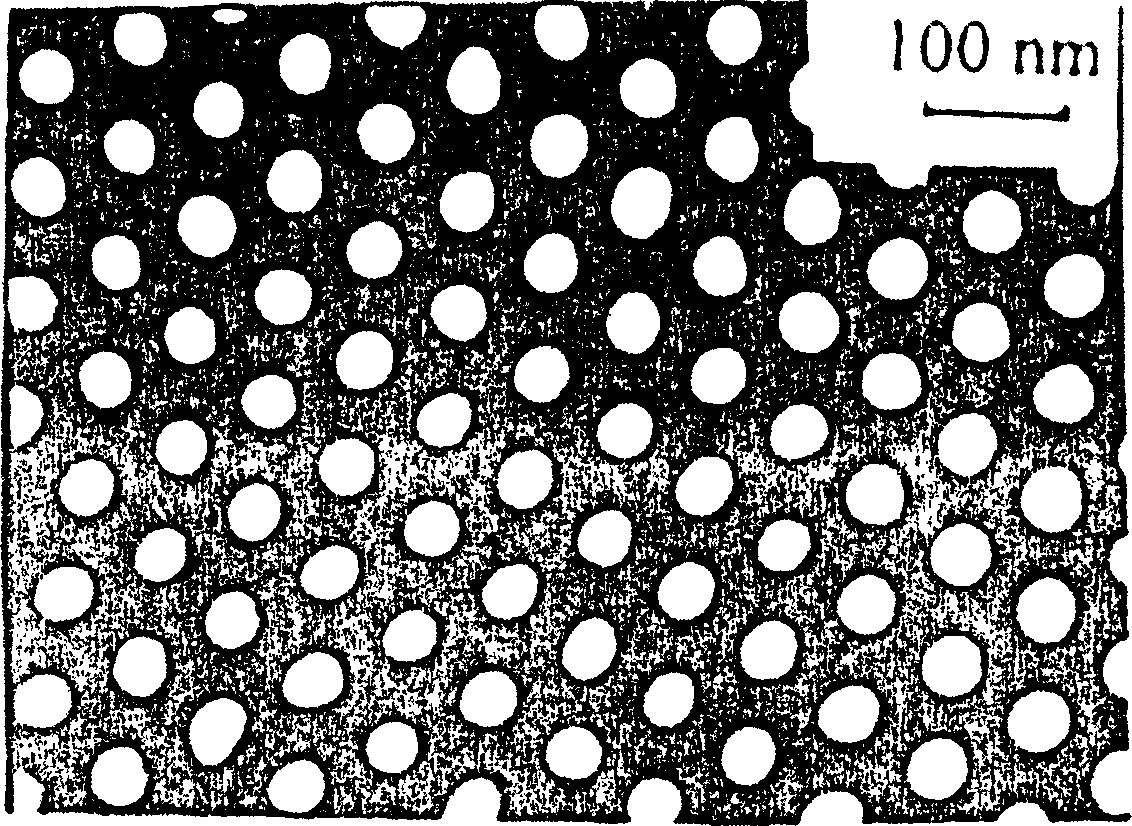

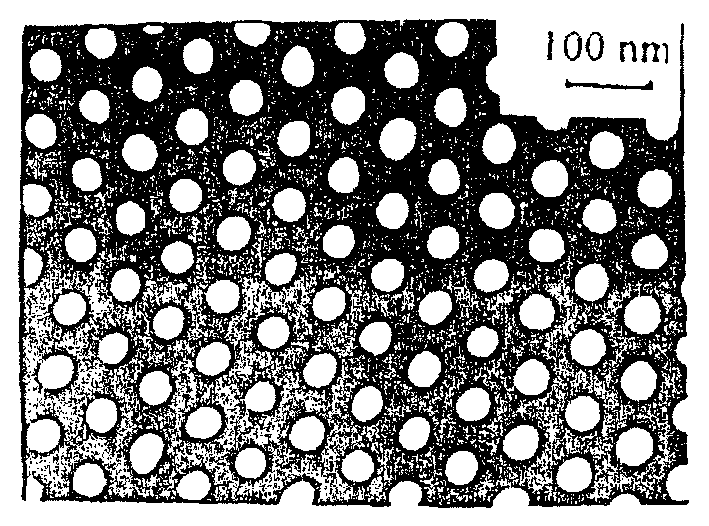

[0008] The embodiment of the method of the present invention: the embodiment of preparing large-scale nano-ordered hole templates on metal aluminum or aluminum alloy is divided into three steps, the first step is to produce hexagonal symmetrical large-area nano-ordered patterns; the second step is to perform electrochemical anode Oxidation, the third step is to adjust the diameter of the hole through the action of the hole-enlarging fluid.

[0009] There are three options for the first step,

[0010] 1. A mother board is made of silicon carbide, single crystal silicon or other materials, and nano-columns with uniform diameters are distributed symmetrically in a hexagonal manner on the board. Cover a layer of polymer material film (such as PMMA) on a flat aluminum (or aluminum alloy) substrate, and use polycool film, etc., to press the mother board on the polymer ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com