Porous aluminium alloy and its producing method

A manufacturing method and aluminum alloy technology, applied in the field of porous aluminum alloy and its manufacturing, can solve the problems of general strength and hardness, low thermal cracking tendency, low plastic toughness, etc., and achieve high normal temperature strength, improved machinability, and mechanical properties Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A kind of porous aluminum alloy related to aluminum alloy material, including aluminum and copper, wherein, copper accounts for 1%-11% (mass fraction) of the total amount of alloy, preferably copper is selected as copper accounts for the total amount of alloy The mass fraction is 4.5%-5.5%. The alloy also includes manganese accounting for 0.6%-1.0% of the total mass fraction of the alloy, including titanium accounting for 0.1%-0.3% of the total mass fraction of the alloy. The alloy includes Cadmium with a fraction of 0.1%-0.25%, including vanadium not greater than 0.4% of the total mass fraction of the alloy, boron not greater than 0.1% of the total alloy mass fraction, zirconium not greater than 0.3% of the total alloy mass fraction and not more than 0.3% of the total alloy mass fraction Rare earth with a mass fraction of 5%, specifically, copper can be selected to account for 1%, 3.5%, 4.5%, 5%, 5.5%, 7.8%, 10% or 11% of the total mass fraction of the all...

Embodiment 2

[0021] Embodiment 2: the present invention is made up of aluminum, copper, titanium and cadmium, copper and alloy total mass fraction 1%~11%, manganese accounts for 0.6%~1.0% of alloy total mass fraction, titanium accounts for alloy total mass fraction percentage of 0.1% to 0.3%, cadmium accounts for 0.1% to 0.25% of the total mass fraction of the alloy, and the rest is aluminum. Specifically, copper can be selected to account for 1%, 3.5%, 4.5%, and 5% of the total mass fraction of the alloy. %, 5.5%, 7.8%, 10% or 11%, manganese can be selected to account for 0.6%, 0.65%, 0.8%, 0.92% of the total mass fraction of the alloy and 1.0%, titanium can be selected to account for 0.1% of the total mass fraction of the alloy %, 0.15%, 0.2% or 0.3%, and cadmium can be selected to account for 0.1%, 0.125%, 0.2% or 0.25% of the total mass fraction of the alloy.

Embodiment 3

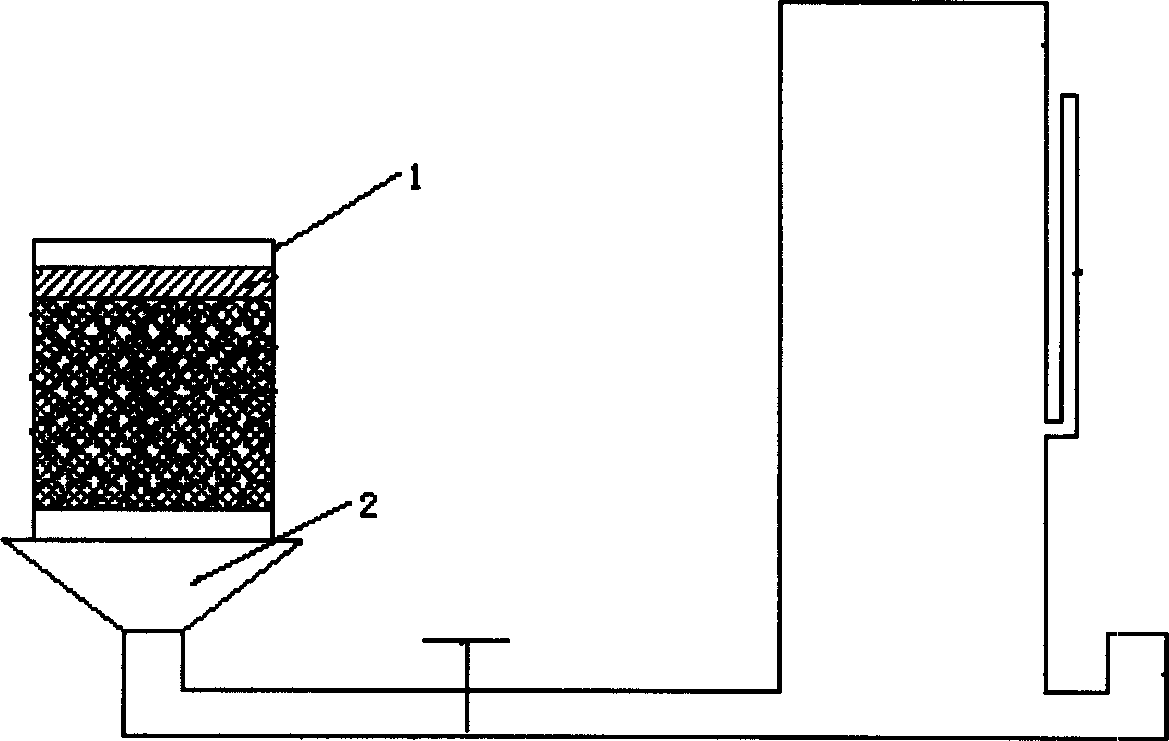

[0022] Example 3: A manufacturing method of a porous aluminum alloy used to manufacture porous aluminum alloys, the first step: placing the filled particles in the mold 1 for compaction and heating to 500°C-650°C for a heat preservation time of not less than 10 minutes; the filling particles can be soluble particles, such as: potassium phosphate, or insoluble particles such as glass balls; the second step: place the mold 1 on the suction cup base 2, and then pour the molten aluminum alloy into the mold inside, and the mold 1 is connected to the negative pressure device through the suction cup base 2. The negative pressure device can be composed of a mold, a suction cup base, a pump or other suction devices, so that the aluminum alloy can penetrate between the filling particles; the third step: wait for the aluminum After the alloy is solidified, take out the filler particle metal complex, remove the filler particles, and finally carry out solid solution aging. In the first step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com