Methylene phosphonic carboxylic acid, its preparation process and its application in water treatment

A technology of phosphine carboxylic acid and methylidene is applied in the field of preparation of methylidene phosphine carboxylic acid water stabilizer, and can solve the problems of low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

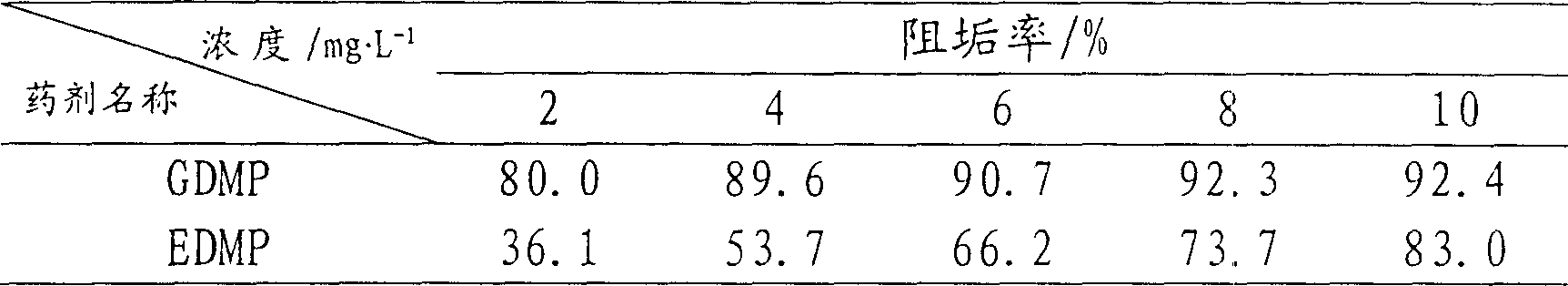

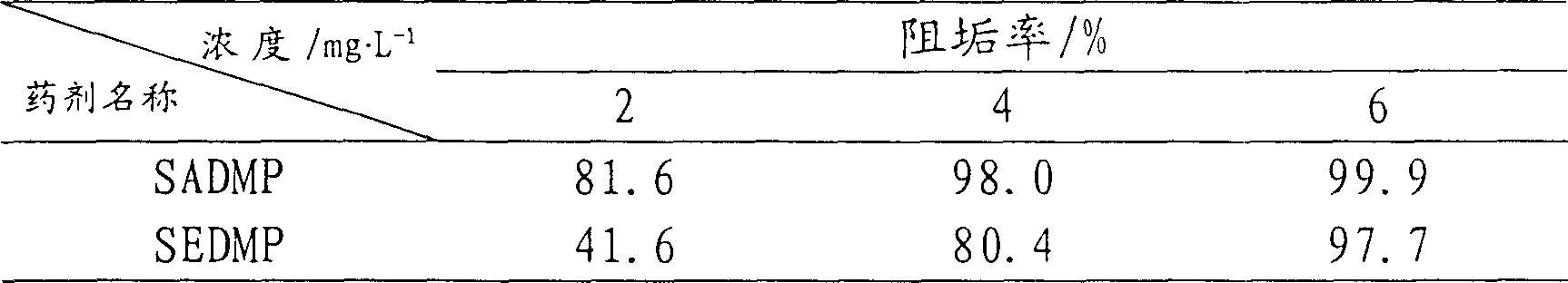

Examples

Embodiment 1

[0016] Add 73.57g (0.5mol) of glutamic acid and 70mL of water into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel and thermometer, and start stirring to fully dissolve glutamic acid. At room temperature (20°C), slowly add 137.5g (1.0mol) of phosphorus trichloride dropwise to the bottle, and control the drop within 2 hours, and keep the temperature in the four-necked flask not higher than 60°C with a cold water bath. After the phosphorus trichloride is added dropwise, raise the temperature to 90°C, add 121.6g (1.5mol) formaldehyde solution dropwise into the bottle, keep the temperature at 90-95°C for 4 hours, until no hydrogen chloride is released from the upper end of the reflux cooler. Cool to obtain glutamic acid dimethylphosphonic acid (EDMP) aqueous solution, concentrate and precipitate 160.0 g of EDMP under the action of methanol, and the product yield is 95.5%.

Embodiment 2

[0018] Except that the reaction time is 7h, all the other conditions are the same as in Example 1, and the results are listed in Table 1.

Embodiment 3

[0020] Except that the reaction time is 10h, all the other conditions are the same as in Example 1, and the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com