Coal gasification grey water dispersing agent and preparation method thereof

A dispersant and gray water technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve facility scaling and blockage, impact on production capacity and benefits, and affect the safety and stability of production equipment Operation and other problems, to achieve continuous and stable operation, excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] (1) Picking materials: 150kg of tricarboxylic butane phosphate, 100kg of polymaleic anhydride, 150kg of acrylic acid-acrylamide sulfonate binary copolymer, and 600kg of tap water.

[0030] (2) Feeding: Inhale tap water into a 3T reactor, keep the temperature at 30-40°C, and start stirring; put tricarboxylic butane phosphate and polymaleic anhydride into the reactor in turn, and add acrylic acid-acrylamide sulfonate The binary copolymer is sucked into the reactor, stirred for 30 minutes, and mixed evenly;

[0031] (3) Stand still: After standing still for 30 minutes, cool to normal temperature, take a sample and check that there is no precipitation after precipitation;

[0032] (4) Filtration: the finished product is obtained after filtration and packaging.

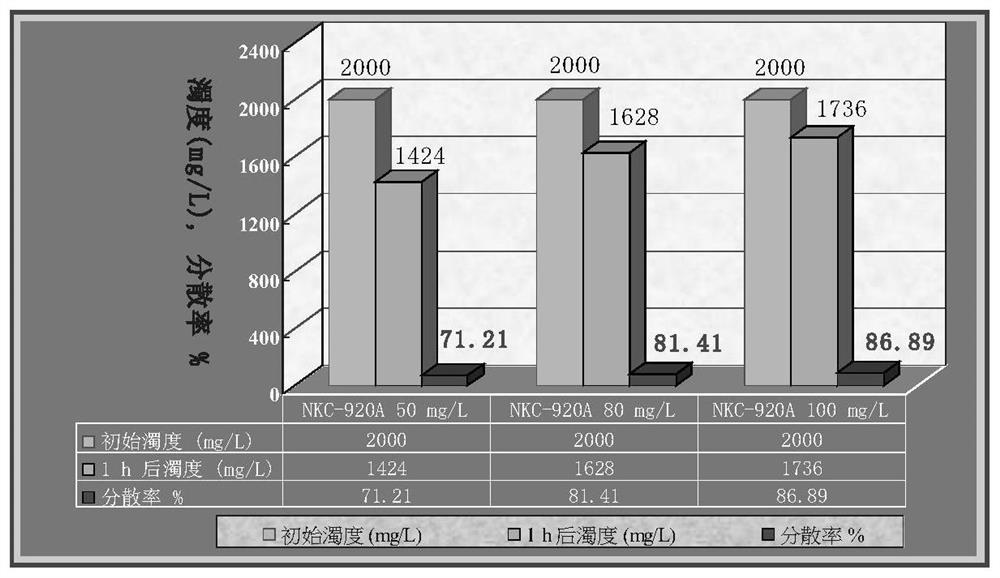

[0033] Such as figure 1 It can be seen from the dispersion rate test chart that the dispersion rate test conditions are 200mg / L calcium hydride, 200mg / L bicarbonate, 2000 200mg / L black water suspension, pH 8.8, au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com