Preparation of active zinc oxide from zinc dross by ultrasonic-microwave process

A technology of active zinc oxide and zinc dross, which is applied in the direction of improving process efficiency, can solve the problems of limiting the wide application of ultra-fine active zinc oxide, high production cost of ultra-fine active zinc oxide, and high energy consumption in the process, so as to shorten the calcination process. Time, overcome local overheating, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

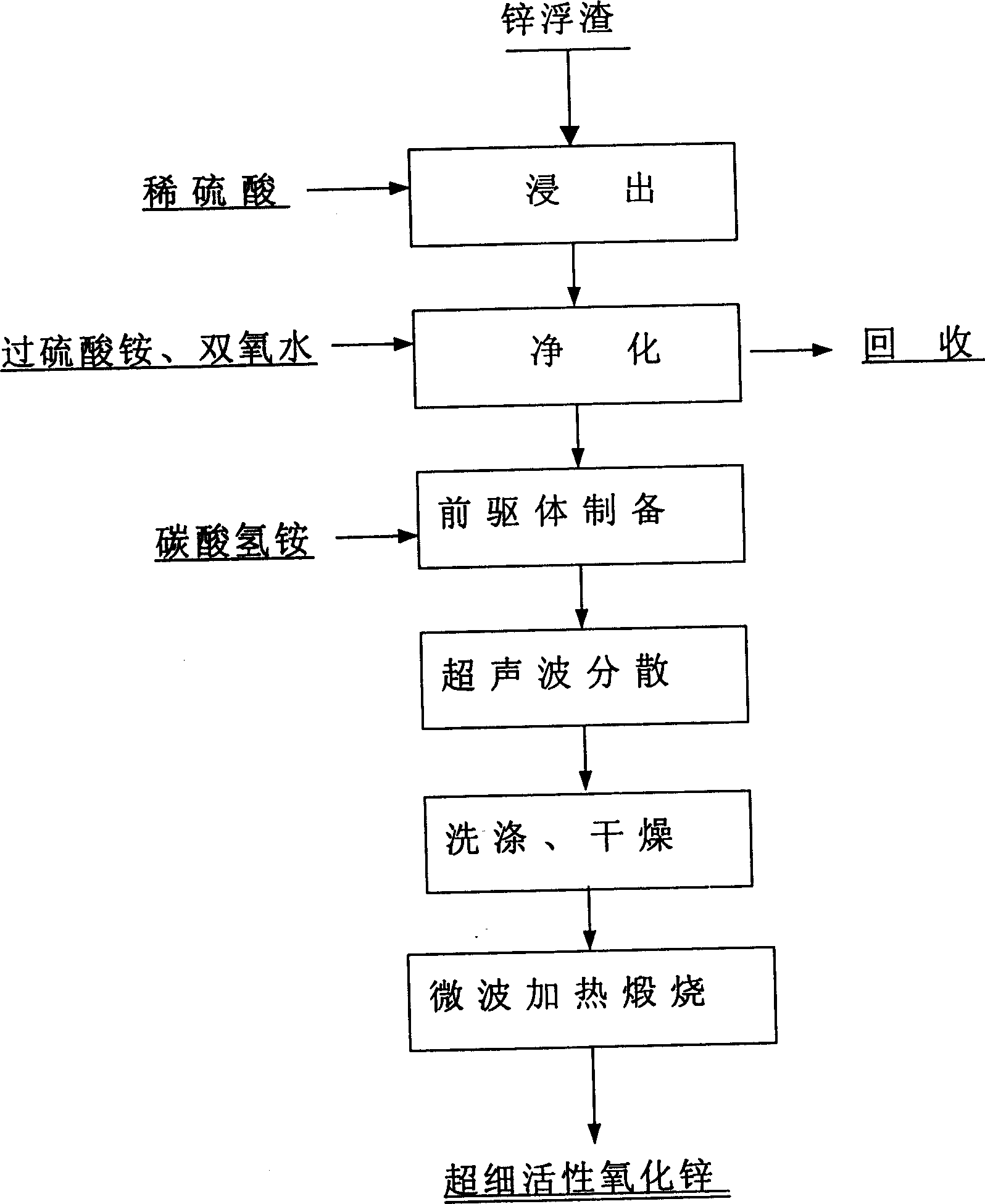

Method used

Image

Examples

Embodiment 1

[0029] 1. Raw materials

[0030] Zinc dross is taken from a zinc factory, its composition and weight percentage: Zn 75-80%, Fe0.5-0.7%, S 1.2-2.0%, Cd (trace), Pb 0.087%, SiO 2 0.31%, As 0.088%, Sb 0.0023%, Co 0.0006%, Mn 0.84%, CI 0.5-2.0%.

[0032] Use dilute sulfuric acid (1.4mol / L) to leach 1000g of zinc scum. The leaching conditions are as follows: the temperature is normal temperature, leaching and stirring for 50min, leaching for 2h, and the solid-liquid ratio is 1:6. Under this condition, the leaching rate of zinc is 92.5%. The leaching solution is filtered to remove SiO in the raw material 2 .

[0033] 3. Zinc sulfate solution purification

[0034] The purification of zinc sulfate solution is divided into three stages of purification, the first stage removes manganese; the second stage removes iron and arsenic; the third stage removes impurities such as lead, cadmium, and cobalt.

[0035] 3.1 Manganese removal

[0036] Ammonium ...

Embodiment 2

[0046] 1. Raw materials

[0047] Zinc dross is taken from a zinc factory, its composition and weight percentage: Zn 74-84%, Fe0.5-0.68%, S 1.6-2.0%, Cd (trace), Pb 0.08%, SiO 2 0.30%, As 0.078%, Sb 0.004%, Co 0.0008%, Mn 0.54%, CI 0.8-2.2%.

[0048] 2. Zinc dross leaching

[0049] Use dilute sulfuric acid (1.8mol / L) to leach 2000g of zinc scum. The leaching conditions are as follows: the temperature is normal temperature, the leaching is stirred for 60min, the leaching is 1.8h, and the solid-liquid ratio is 1:8. Under this condition, the leaching rate of zinc is 93.0%. The leaching solution is filtered to remove SiO in the raw material 2 .

[0050] 3. Zinc sulfate solution purification

[0051] 3.1 Manganese removal

[0052] Ammonium persulfate is used to directly remove manganese in zinc sulfate solution. The optimal process conditions for manganese removal are: temperature 93°C, pH value 5.4, reaction 3.5h, manganese removal rate over 99.90%, manganese content 0.00014...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com