Chargeable magnesium battery

A magnesium battery and battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low open circuit voltage, achieve good safety, great development and application prospects, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Production of Negative Electrode

[0026] MgH 2 Mix with metal elements Ni and Ti in a molar ratio of 1:0.01:0.01, ball mill for 6 hours under argon atmosphere, keep warm for 4 hours at 560°C under argon atmosphere, cool, and then ball mill in a high-speed ball mill for 80 hours, the powder size 50-600nm, put the magnesium alloy powder into 0.01M magnesium fluoride and soak for 1 minute, make the magnesium alloy powder, carbonyl nickel powder and PTFE into a paste, coat it on the copper mesh, press it under 30MPa pressure to make a diameter of 13mm, The negative electrode sheet with a thickness of 1 mm was stored in a vacuum desiccator.

[0027] Positive electrode production

[0028] Weigh an appropriate amount of CoCl 2 ·6H 2 O and MgCl 2 ·6H 2 O, the molar ratio of the two is 2:1, prepare a mixed solution with a certain concentration, adjust the pH to 6~7 with ammonia water, and then add it to an appropriate amount of oxalic acid solution, a large amount of prec...

Embodiment 2

[0033] Negative pole piece is made identical with embodiment 1

[0034] Production of the positive pole piece

[0035] Under hydrogen atmosphere, (NH 4 ) 2 MoS 4 Heating at 850°C for 6 hours, cooling, and ball milling in high-speed ball milling for 80 hours, the powder particles are in the range of 50-800nm, and the MoS 2 Powder, acetylene black powder, and PTFE (85:10:5) were mixed into a paste, coated on an aluminum mesh, pressed into a positive electrode sample with a diameter of 13 mm and a thickness of 1 mm under a pressure of 30 MPa, and stored in a vacuum desiccator.

[0036] Assembly of simulated battery

[0037] In addition to using MoS 2 Positive pole piece replaces MgCo 2 o 4 Except for the positive pole piece, others are exactly the same as in Example 1.

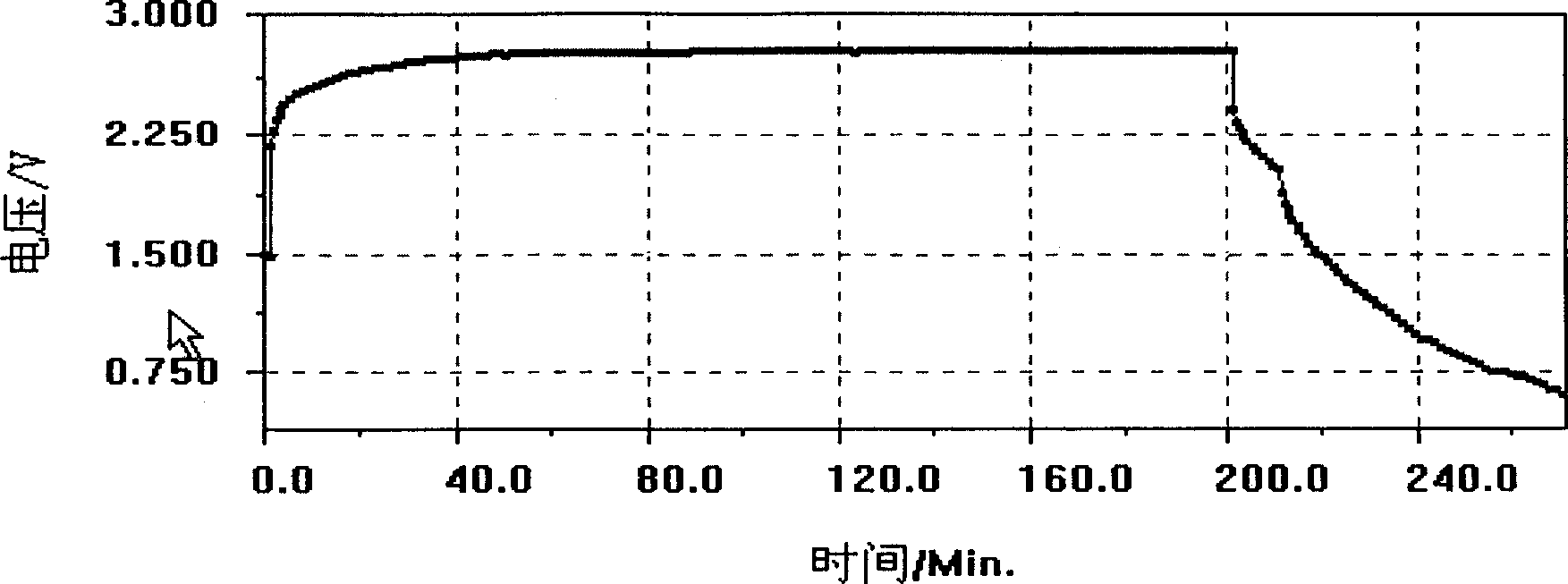

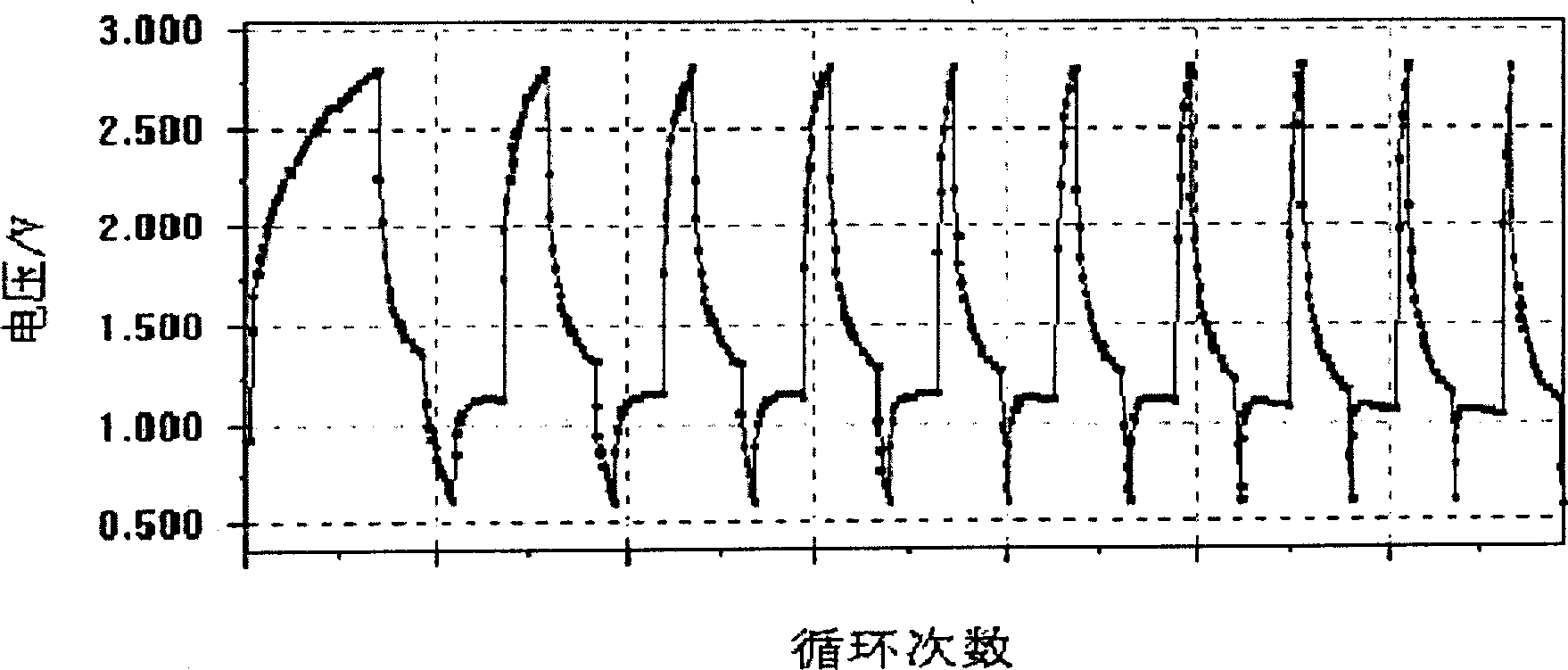

[0038] The opening voltage of the simulated battery is 1.4V, 0.1C charging and discharging, and the charging voltage is stable at 2.8V. The simulated battery can be reversibly charged and discharged, and ...

Embodiment 3

[0040] Mix Mg powder, metal copper powder and nickel powder in a molar ratio of 1:0.01:0.005, ball mill for 6 hours in an argon atmosphere, heat at 560°C for 4 hours in an argon atmosphere, cool, and ball in a high-speed ball mill for 80 hours , the powder size is in the range of 80-800nm, the magnesium powder is soaked in 0.01M magnesium fluoride for 3 minutes, the magnesium alloy powder, carbonyl nickel powder and PTFE (85:10:5) are adjusted into a paste, and coated on the copper On the net, under a pressure of 30MPa, press it into an electrode sheet with a diameter of 13mm and a thickness of 1m, and store it in a vacuum desiccator.

[0041] The production of the positive electrode sheet is the same as in Example 1.

[0042] The fabrication of the simulated battery is the same as in Example 1.

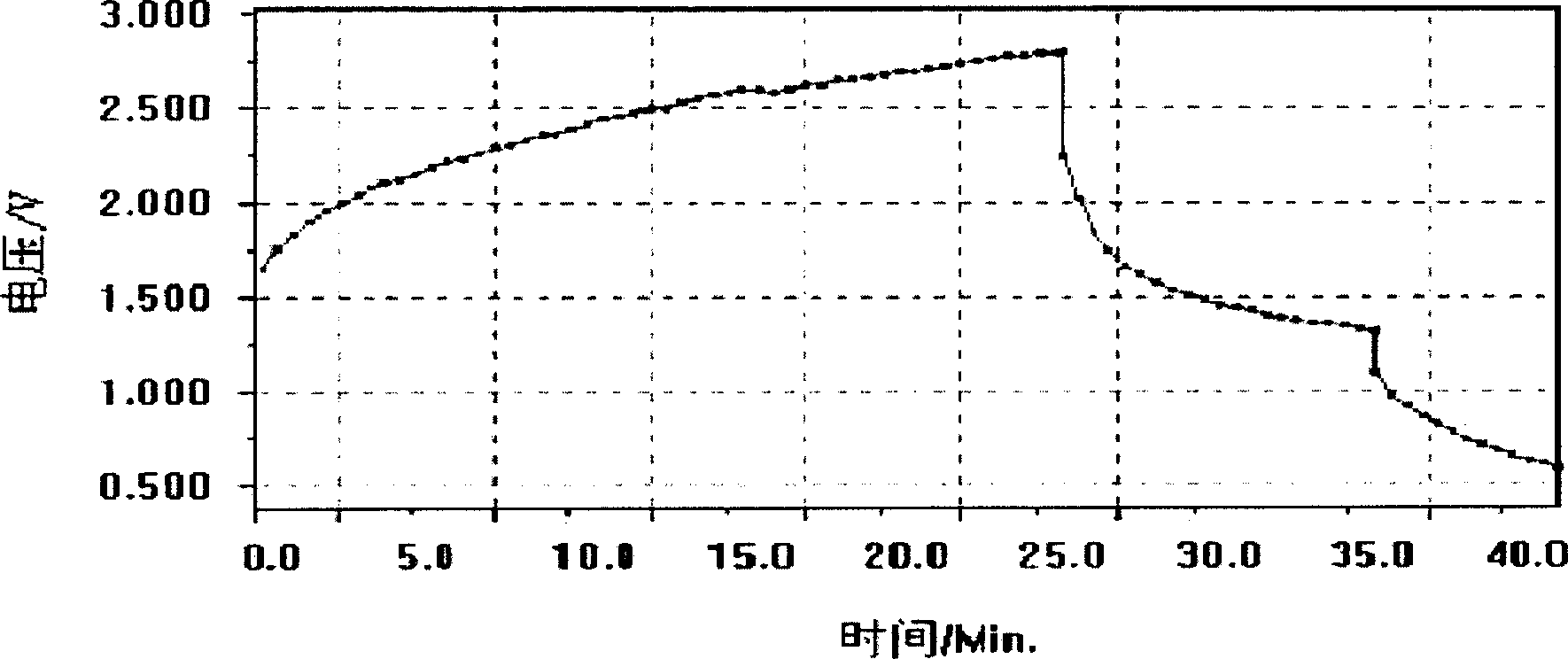

[0043] The opening voltage of the simulated battery is 2.0 volts, and it is charged and discharged at 0.1C. The average charging voltage is about 2.85 volts, and the discharging vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com