Production of alcohol by fermenting by yeast tolerant to high concentrated sugar and alcohol

An alcohol fermentation and high-concentration technology, applied in fermentation, biofuels, etc., can solve the problems of reducing sugar utilization, low alcohol concentration, and alcohol conversion rate, and achieves the goals of easy implementation, reduced production costs, and increased alcohol content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

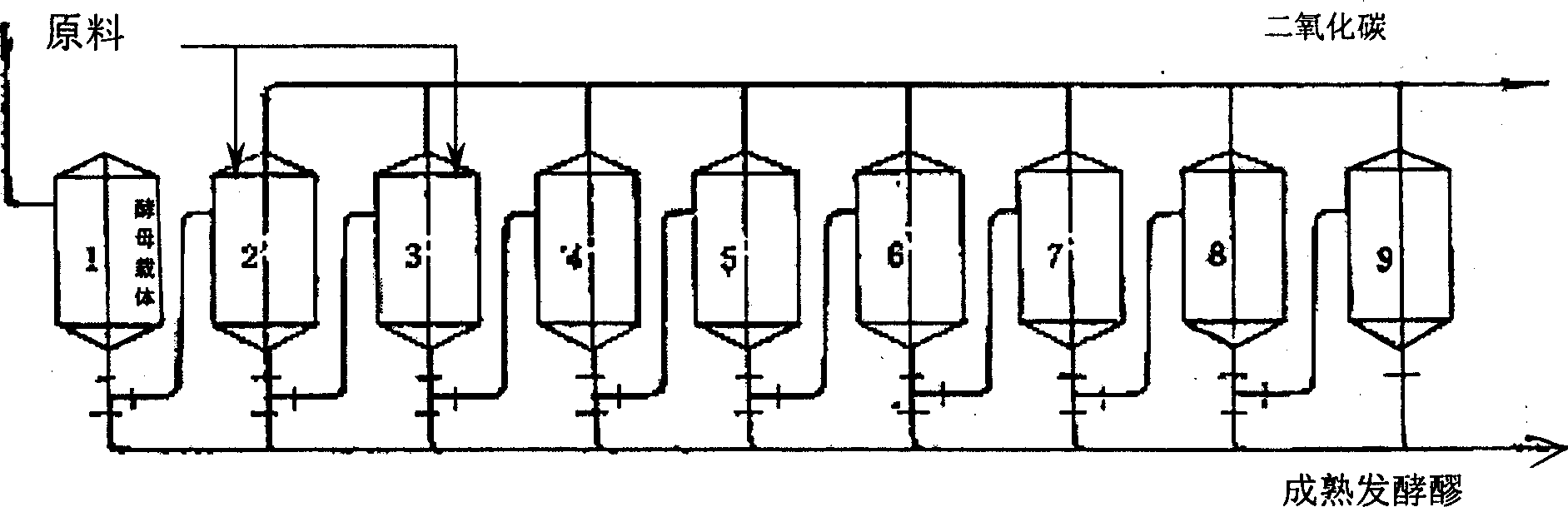

Method used

Image

Examples

Embodiment 1

[0021] The 1912 strain was cultured according to the conventional liquid seed culture method of microbial fermentation, with the wort medium (take the wort used in the brewery with 10 degrees) for cultivation, after a series of cultures such as shake flasks, seed tanks, etc., when each milliliter of culture solution contains Yeast count reaches 1×10 8 Hour, input 90M according to 1 / 15 of the fermenter culture solution 3 Cultivate in the fermenter, which contains 10-15M 3 Sterilized culture solution with a sugar concentration of 10%. The temperature is controlled at 28°C, the pH value is controlled at 4.5, and the sterile air is kept continuously or intermittently, that is, ventilation is performed every 1 hour for 10 minutes. Check the amount of yeast cells in the culture solution to reach 10 yeast cells per milliliter of culture solution 8 At a time, add a high-concentration sugar-containing culture solution to make the sugar concentration of the entire culture solution 15% by we...

Embodiment 2

[0023] The specific operation is the same as in Example 1, the difference: the seed culture stage is aerated for 20 minutes every 1 hour, when the culture solution contains 10 yeasts 8 At this time, the added sugar concentration of the culture solution was 23% by weight, and the mixture was kept stirring or sterile air was passed for 12 minutes every 2 hours, and the final alcohol concentration by volume reached 13%.

Embodiment 3

[0025] The specific operation is the same as that in Example 1, the difference: the seed culture stage is aerated for 30 minutes every 1 hour, when the culture solution contains 10 yeasts 8 At this time, the added culture solution has a sugar concentration of 30% by weight, and keep stirring or pass sterile air every 2 hours for 20 minutes, and the final alcohol concentration by volume will reach 14%.

[0026] Table 1. Single-tank fermentation results of 1912 strain from Yuanjiang Sugar Factory in Yunnan Province

[0027] Item

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com