Method for producing semiconductor apparatus

A semiconductor and device technology, applied in the field of manufacturing semiconductor devices, can solve the problems of multi-layer interconnect leakage current and device misoperation, and achieve the effect of solving leakage current and device misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

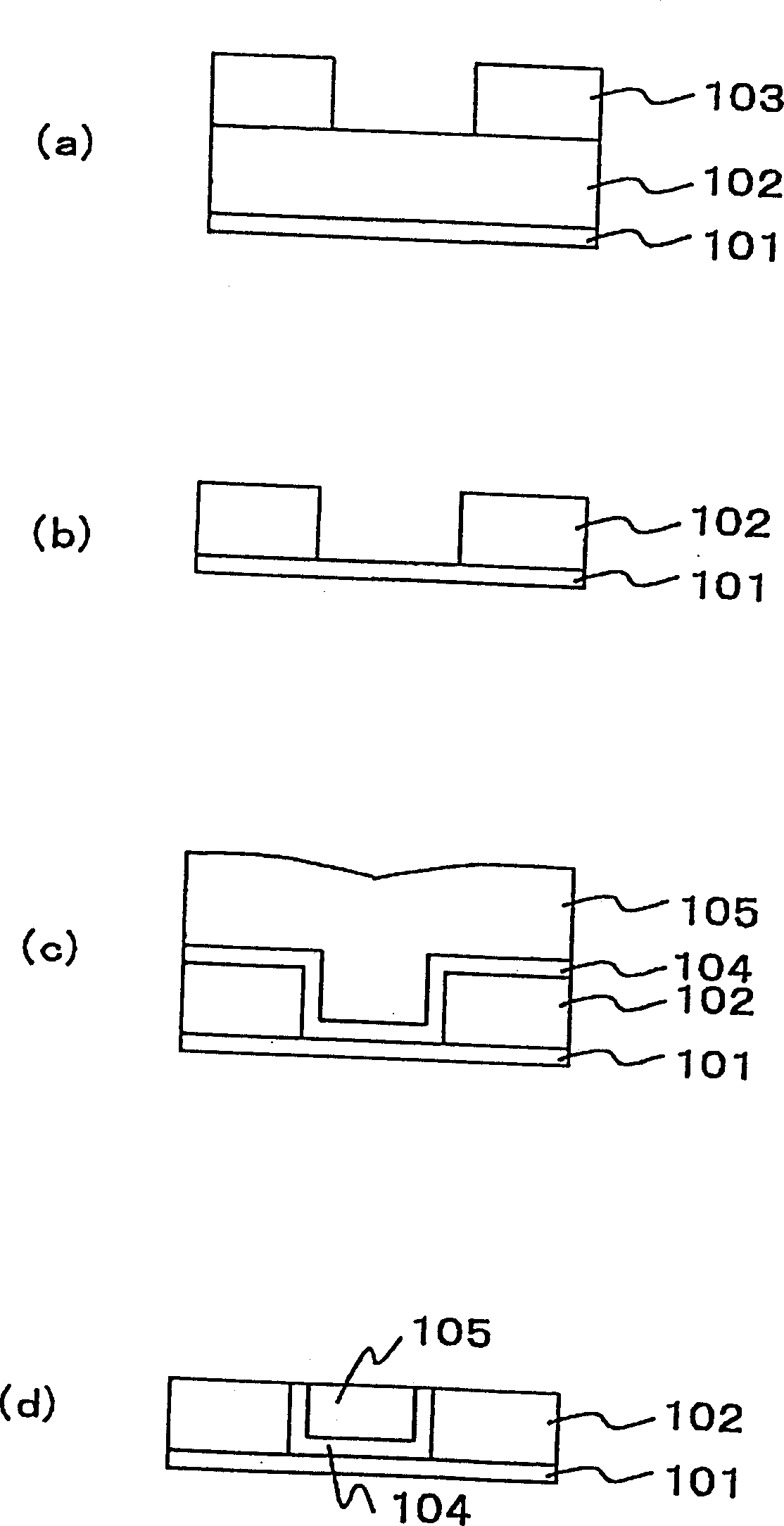

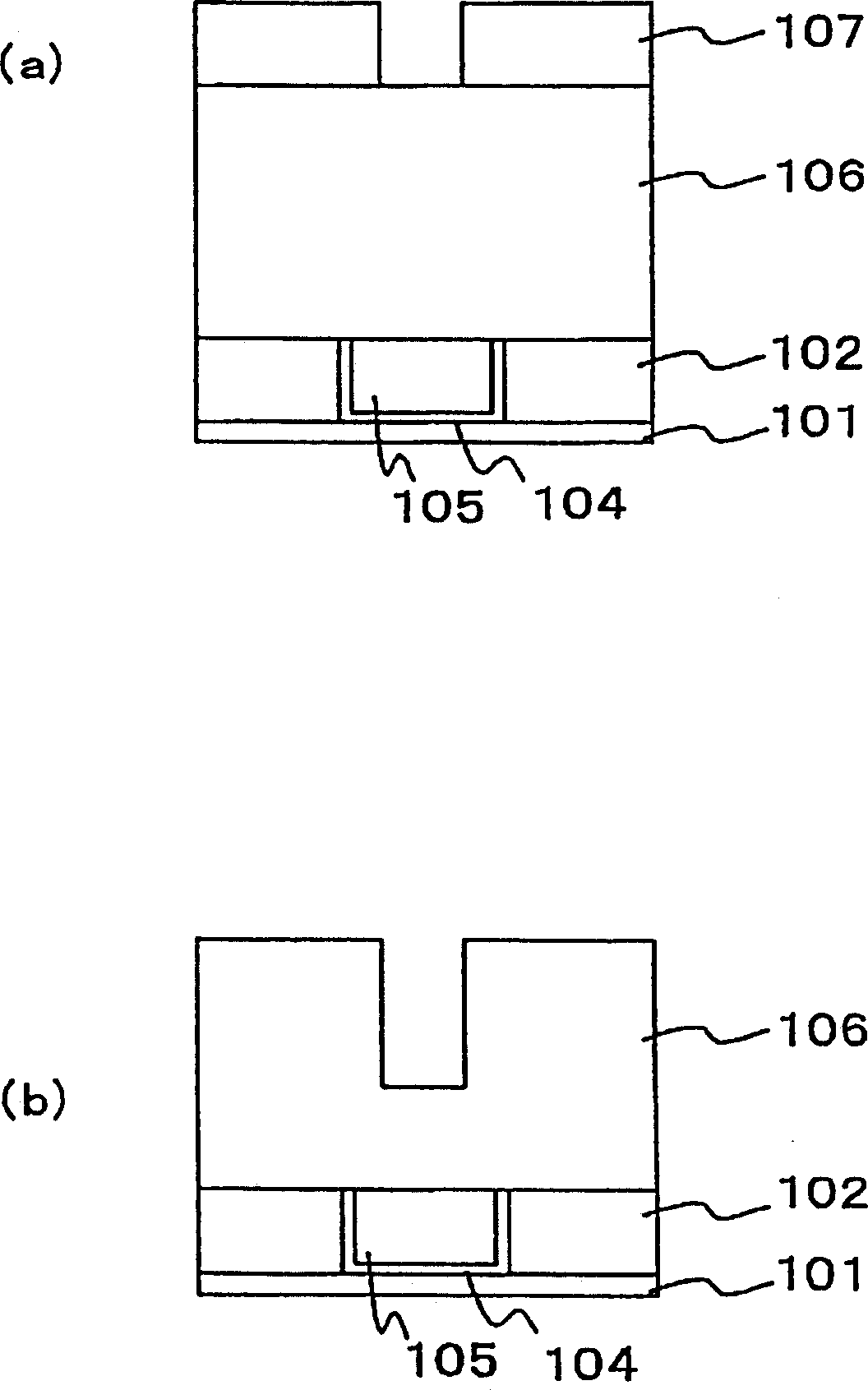

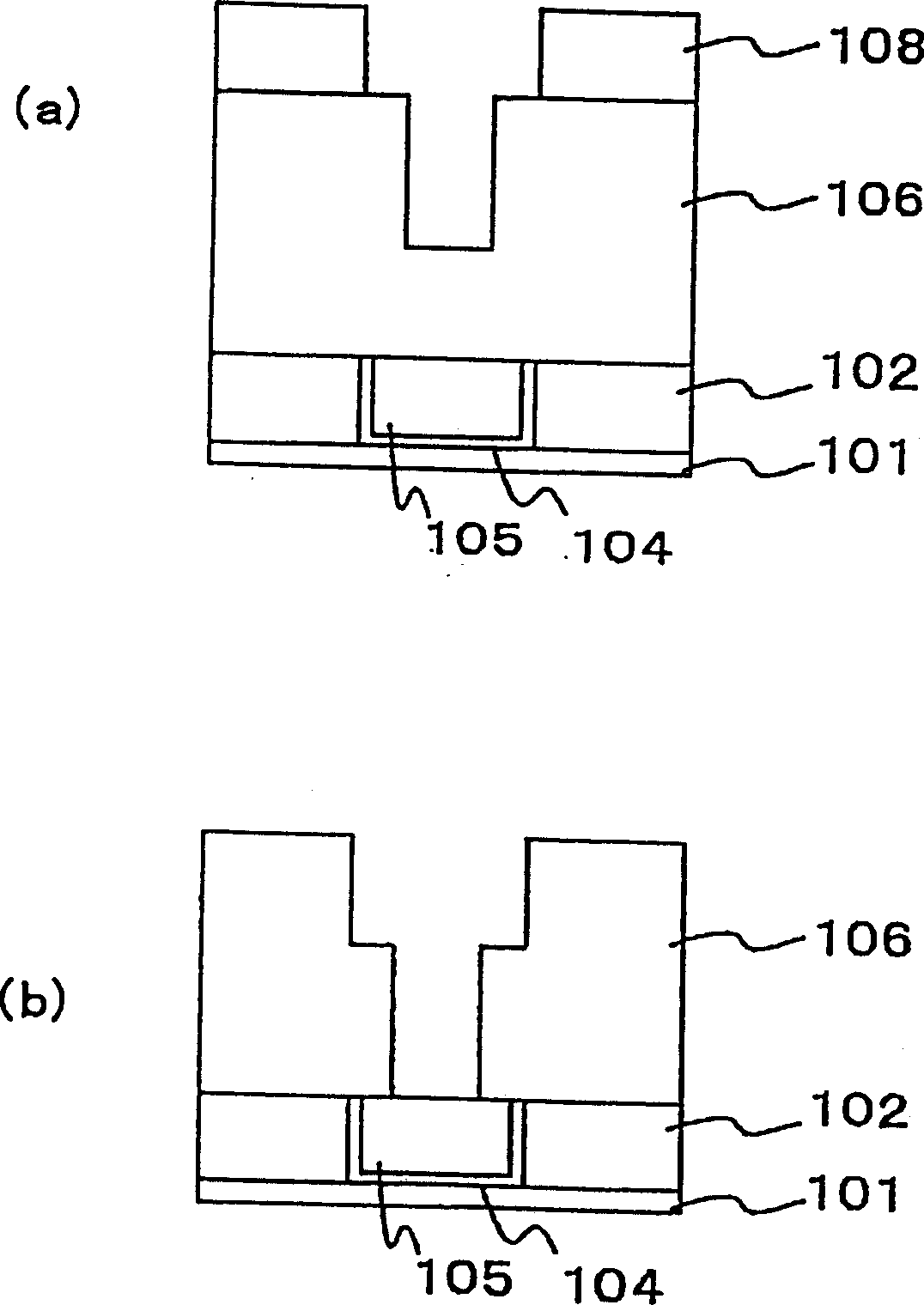

[0068] refer to Figure 1-4 Describe this example. This example employs a damascene interconnection for each of the lower wiring and the upper wiring, and uses a so-called dual damascene process method.

[0069] (Formation of lower wiring)

[0070] First, the lower wiring is fabricated as follows. On a semiconductor substrate (not shown) on which devices such as transistors are formed, a silicon oxide film 101 having a thickness of 100 nm and an HSQ film 102 having a thickness of 400 nm are formed. Next, a photoresist mask 103 with a predetermined pattern is formed thereon [ figure 1 (a)]. Dry etching is performed using this mask to form grooves for burying lower wiring in the HSQ film 102 . Subsequently, the photoresist mask 103 is peeled off by performing ashing with oxygen plasma and cleaning with a cleaning solution containing an amine compound.[ figure 1 (b)].

[0071] Next, on the entire surface of the obtained substrate, a TiN film 104 (thickness: 50 nm) was fo...

example 2

[0080] In this example, a silicon nitride film is formed on the lower wiring, which is used as an etch stopper film when forming a via hole. Thus, it is desired to suppress the lower wiring made of copper and reduce the amount of metal contamination adhering to the inner wall of the via hole. The manufacturing steps will be described below with reference to the drawings.

[0081] First, press the figure 1 The same process shown in the form of the lower wiring, as figure 1 (a)-1(d). Then, a silicon nitride film 120 having a thickness of 100 nm is formed thereon by CVD. Furthermore, the HSQ film 106 and the resist film 107 were formed in the same manner as in Example 1 [ Figure 10 (a)]. Each pore diameter of the resist film 107 is 0.25 μm.

[0082] Next, dry etching is performed using this resist mask 107 to form a part of a via hole in the HSQ film 106 . As a corrosive gas, use a 4 f 8 and Ar mixed gas. The dry etching is terminated before the bottom of the via hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com