Light-emitting diode

A technology for light-emitting diodes and light-emitting components, which is applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reduced size and lack of brightness, and achieve the effect of increasing brightness and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The invention will now be illustrated by specific examples. However, the present invention is not limited to these Examples.

[0054] First, a light emitting diode 1 according to a first embodiment of the present invention shown in FIG. 1 will be described.

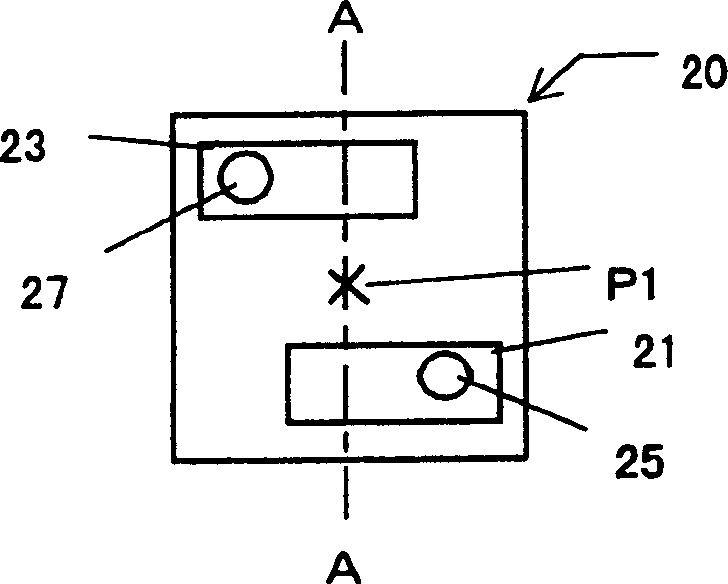

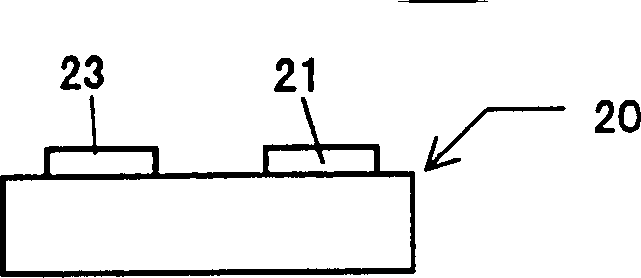

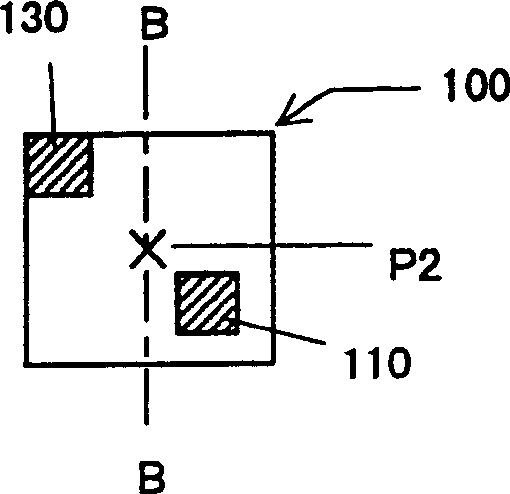

[0055] Before explaining the light emitting diode 1, the structure of a flip chip 100 made of gallium nitride compound semiconductor used in this embodiment will be explained. Figure 3A with 3B A cross-sectional view and a plan view of the flip chip 100 are shown, respectively. Reference numeral 101 denotes a sapphire substrate; 102 denotes a buffer layer made of aluminum nitride (AlN); 103 denotes gallium nitride (GaN) which is high in carrier density (Carrier density) doped with silicon (Si) The n-type semiconductor layer of the gallium nitride compound; 104 represents the In x Ga 1-x An active layer made of N (0y Ga 1-y A p-type cladding layer 105 made of N (02 and 130 represent a negative electrode inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com