Safety type cigarette and its production process and heating smoking requisites

A heating type and smoking set technology, which is applied in the direction of tobacco, tobacco pipe, and tobacco treatment, can solve the problems of inability to solve the pollution of smoking and the harm of passive smokers, the effect of removing harmful substances is not obvious, and cannot meet the psychological needs of smoking, etc., so as to improve Fragrance and health function, easy to promote, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

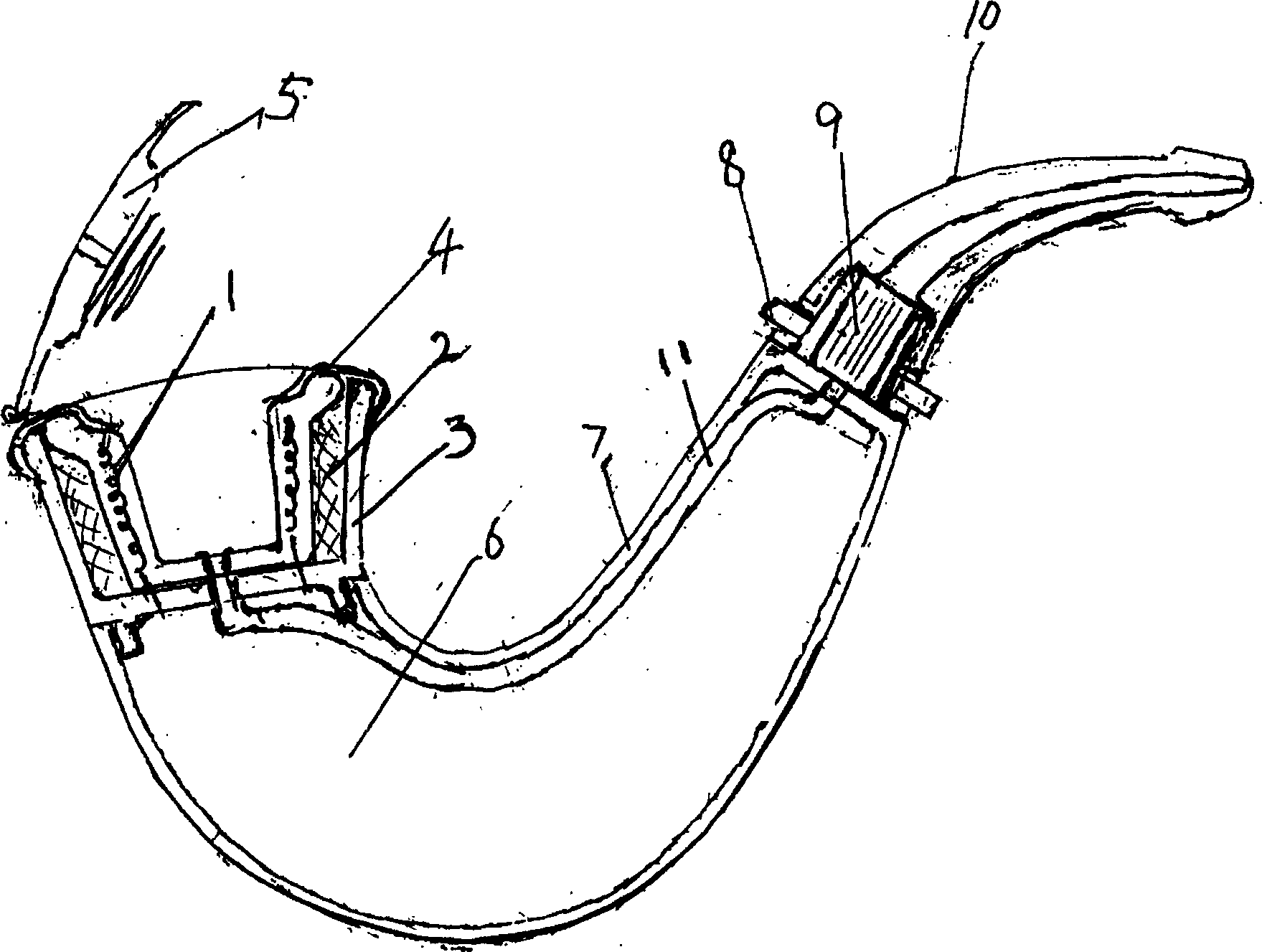

[0010] Embodiment 1: safety type cigarette, shredded tobacco accounts for 70% (volume ratio) of total amount, spice plant accounts for 30%, in the process of producing cigarette by traditional technology, spice plant filament, granule, flake or powder are evenly added to Tobacco. No filter tip is added when rolling, and its shape is a short and thick cylinder. Among the spice plants are: licorice, tonka beans or pods, fenugreek seed fragments. Electric heating smoking set: refer to figure 1 The smoke pot 3 is a cavity for accommodating the whole cigarette. The outer layer of the cavity is provided with an electric heating component 1 made of semiconductor heating ceramics, which is covered with an insulating layer 2 made of asbestos. The outer shell is plastic injection molding. Make the seal 4 with sheet metal. Lid 5 is connected on the sealing with hinge. Power supply 6 is that battery is housed in shell 7, and its shape is consistent with tobacco pipe. The temperature ...

Embodiment 2

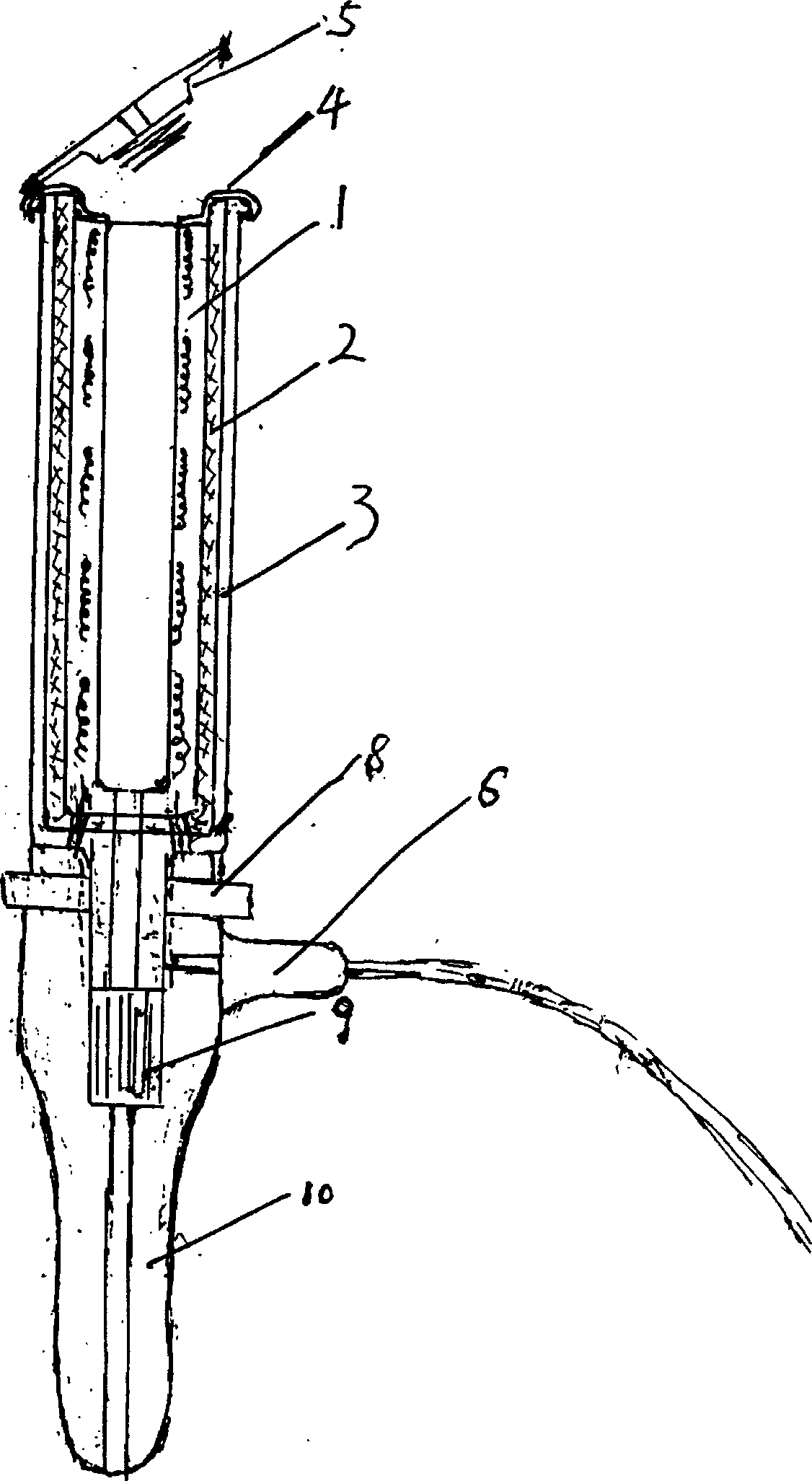

[0011] Embodiment 2: Safe type cigarette is basically the same as the above example, but the proportion of spice plants is 40%, and the kind is filaments and flakes that black tea, cocoa, coffee, etc. are made. The shape of the cigarette is consistent with that of a traditional cigarette. Electric cigarette holder: refer to figure 2 , The electrothermal component 1 is an electrothermal film. The insulation layer 2 is rock wool. The inner cavity of the smoke pot 3 is consistent with the shape of the cigarette. The power supply 6 is an external power supply. The rest is the same as the previous example.

Embodiment 3

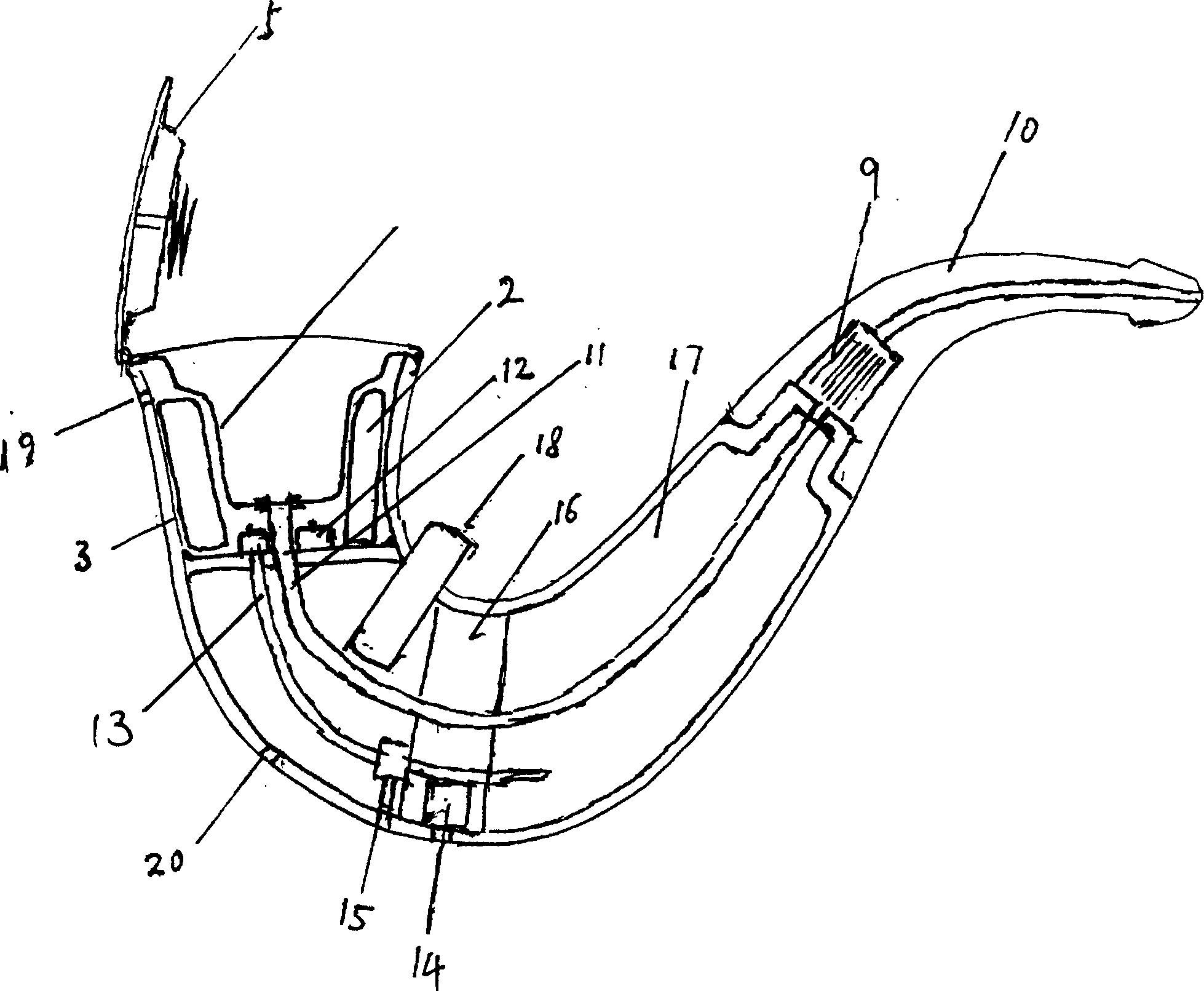

[0012] Embodiment 3: substantially identical with example 1, but the ratio of spices is 50%, and kind is rosemary herb, lavender, dry oregano and hop etc., and shape is identical with example 1. Gas heating smoking set: refer to image 3 , smoke pot 3 is made of stainless steel sheet, is to accommodate the cavity of whole cigarette, and its outer insulation layer 2 adopts refractory material, leaves the gap between smoke pot and refractory material as gas channel. The combustion head 12 is connected with the gas storage tank 17 through the hose 13, and liquefied petroleum gas or butane gas is stored in the gas storage tank. The high-voltage ignition head 18 can generate a high-voltage electric spark to ignite the liquefied gas. Temperature regulating switch 15 can regulate the size of fire head. The gas blocking device 16 is provided with a flue gas channel 11 , a gas channel 13 and an inflator 14 . The flue gas channel runs through the gas storage tank. A filter device 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com