Ferment device of solid ferment aseptic manipulation

A technology of solid-state fermentation and aseptic operation, which is applied in solid-phase fermentation bioreactors, biochemical cleaning devices, enzymology/microbiology devices, etc. Achieve the effect of solving the problem of contamination, shortening the delay period, and solving the problem of easy contamination by manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

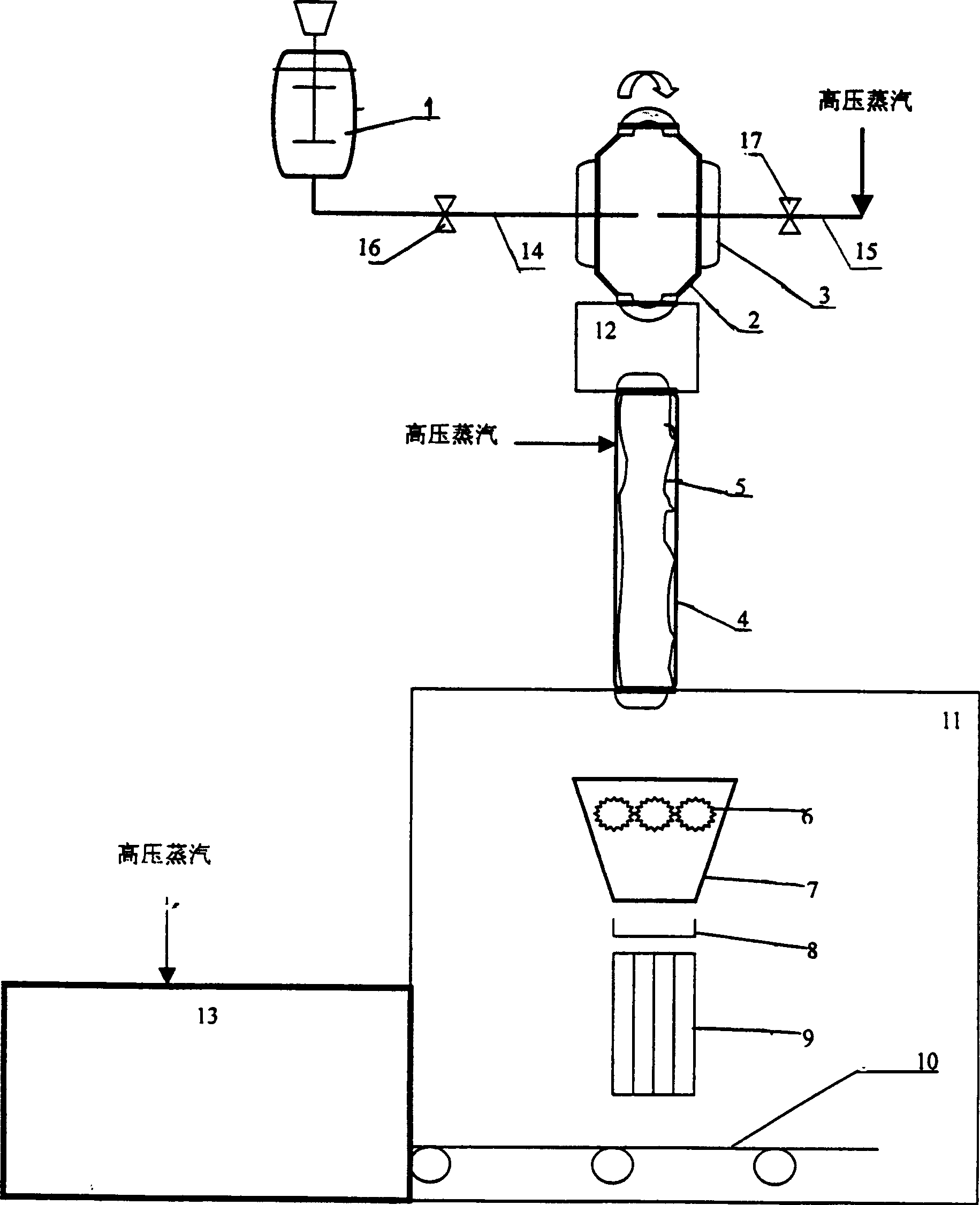

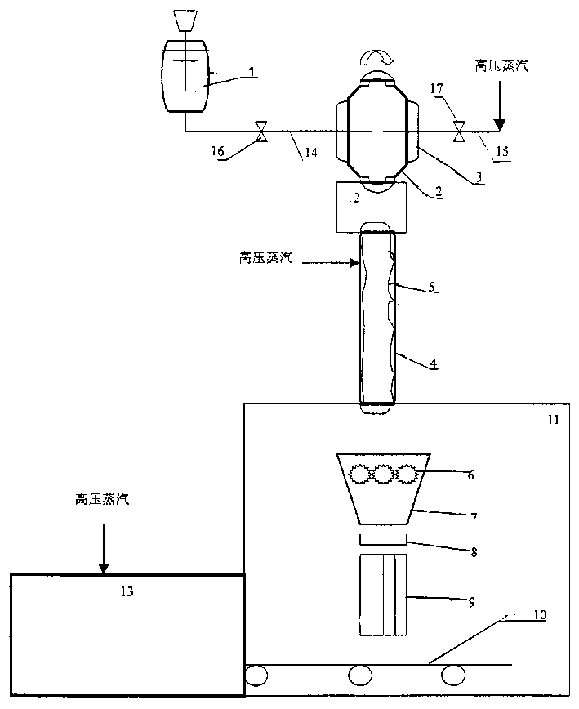

[0033]According to Fig. 1, make a set of fermentation special-purpose device that adopts the aseptic operation of liquid-solid combination, comprising: a standard liquid deep layer standard fermenter as liquid seed tank 1; Inoculation cylinder 4 and solid-state fermentation reactor 13; Solid medium sterilization Tank 2, the solid medium sterilization tank is a pressure vessel equipped with a heating or cooling jacket, and can rotate up and down at 4-10 rpm, and the top and bottom of the tank are conical; mechanical drum sieve inoculation cylinder 7, culture shallow Disc 8, honeycomb cultivator 9, conveyor belt cultivator 10, class 100 ultra-clean room 11 and class 100 ultra-clean operation platform 12 are processed and manufactured according to EMP standard; wherein liquid seed tank 1 passes through pipeline 14 with valve and solid Medium sterilizing tank 2 communicates, and the wall of solid medium sterilizing tank 2 is connected with a pipeline 15 with a valve, and the lower ...

Embodiment 2

[0035] The seed liquid prepared by the liquid fermenter 1, the pressure of the liquid fermenter is increased by sterile air, and the seed liquid is transported to the solid medium sterilization tank 2 after autoclaving; the solid medium is sterilized at 120° C. for 30 minutes, and then , cooling the medium to 30--40°C; solid medium sterilizing tank 2 rotates 3-6 times, so that the liquid seed liquid and solid medium materials are evenly mixed; in the 100-level ultra-clean operation platform 12, quickly culture the solid The lower cover of the base sterilization tank 2 and the upper cover of the sterile inoculation tube 4 are opened, and the inner cloth tube 5 of the sterile inoculation tube is connected to the lower cover of the solid medium sterilization tank 2, and the uniformly mixed materials in the solid medium sterilization tank Drop vertically into the aseptic inoculation cylinder 4; in the 100-class clean room 11, open the lower cover of the aseptic inoculation cylinder...

Embodiment 3

[0039] The operation process of this embodiment is the same as that of Embodiment 1. The difference is that the solid-state fermentation culture is carried out in the solid-state fermentation reactor in the form of a conveyor belt-loaded closed pressure vessel after steam sterilization from a mechanical traction conveyor-type incubator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com