Metal bar continuous zone smelting and solidification grain-refining process

A technology of metal rods and continuous regions, which is applied in the field of continuous region melting and solidification of metal rods, can solve the problems of high melting point alloys, achieve fast heating speed, convenient operation, and eliminate macro segregation and shrinkage porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

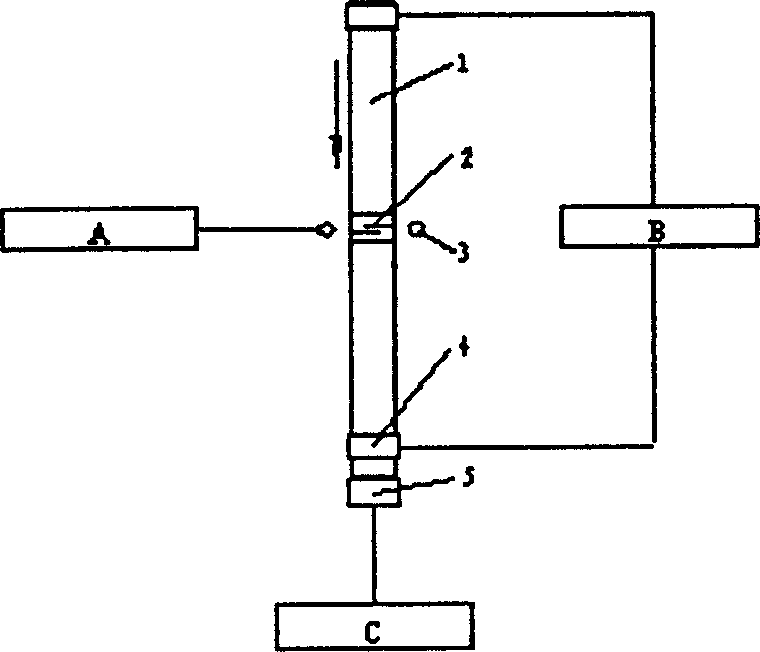

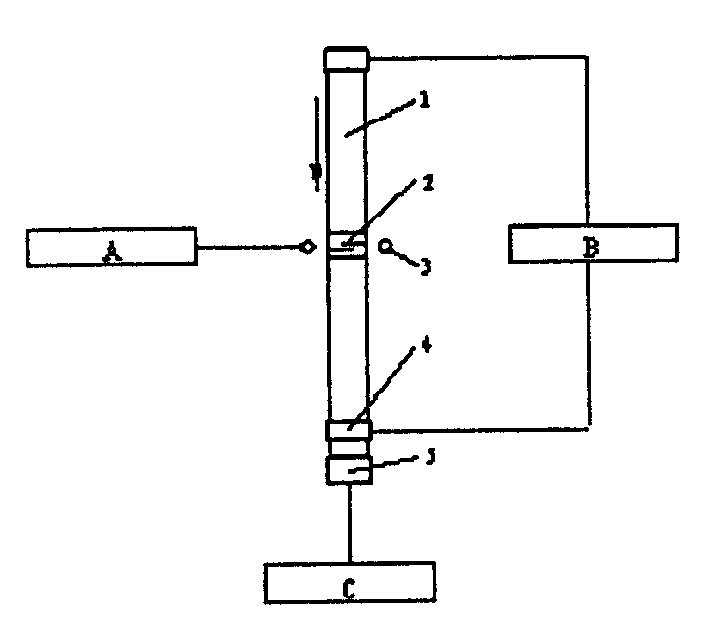

Image

Examples

Embodiment 1

[0014] Embodiment 1: A cast iron rod with a diameter of d=20mm is processed, and its chemical composition and weight percentage content (%) are: C 4.10, Si 1.92, Mn 0.22, P 0.058, S 0.023 Fe balance. Use a high-frequency heating power supply with power of P=15kW and high-frequency electromagnetic frequency f=100KHz, the temperature in the melting zone of the cast iron rod is 1250°C, the descending moving speed of the rod is v=0.2mm / s, and the pulse current parameters are current peak value I= 500A, pulse frequency f'=4000Hz, output voltage U=80V.

[0015] Carry out specific operations according to the arrangement of the attached drawings. Continuous zone melting and continuous solidification are adopted. The zone melting starts from one end of the cast iron rod 1, and then the rod 1 and the induction heating coil 3 are relatively moved through the movement mechanism C, so that the melting zone 2 of the rod 1 gradually moves to the other end. , and gradually complete the melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com