Fresh air air-conditioner with solution heat recoverer

A solution heat recovery device and air conditioner technology, applied in the field of air conditioners, can solve the problems of not being widely used, high material requirements, unfavorable human health, etc., so as to avoid the spread of viruses, avoid cross-contamination, and facilitate popularization and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

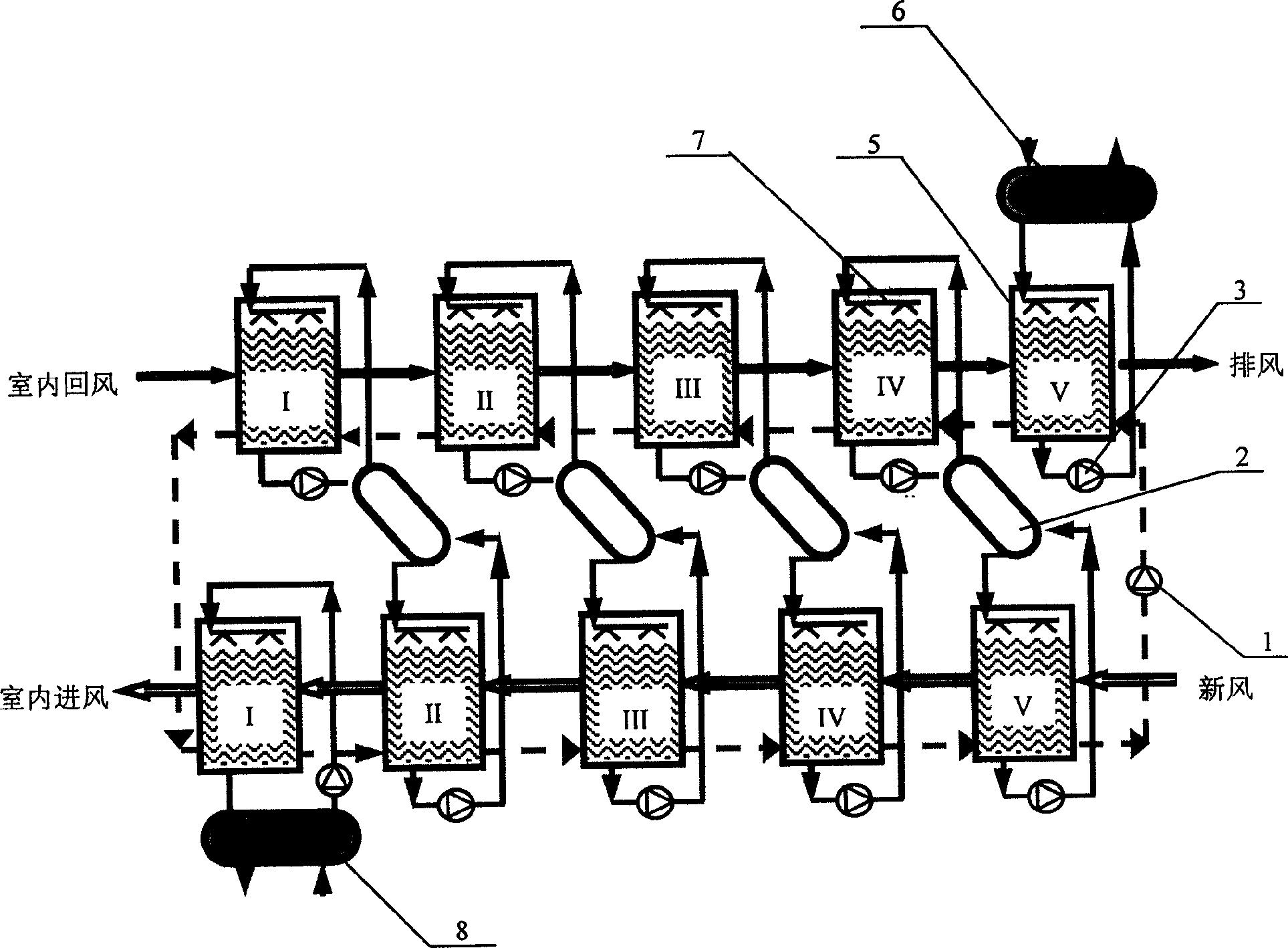

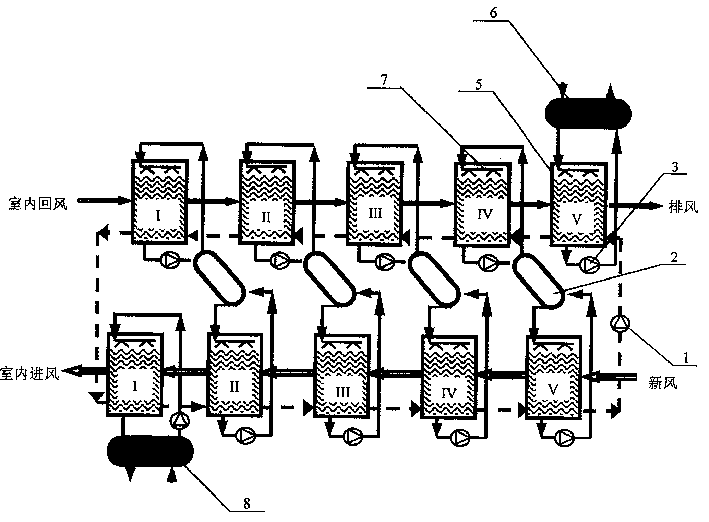

[0014] see figure 1 , the fresh air air conditioner of the present invention comprises circulation pump 1, single-stage spray pump 3, condenser / evaporator 6, evaporator / condenser 8 and the five-stage (I-V) solution heat that is divided into upper and lower two layers and is evenly distributed by filler Recycler 5. Each solution heat recoverer 5 on the upper layer is sequentially connected with the indoor return air duct in series and then sent to the exhaust air duct. Each solution heat recoverer 5 on the lower floor is connected in series with the fresh air duct in the room in turn and then sent into the indoor air intake duct. The inlet of the circulation pump 1 is connected to the bottom of the lower V-level solution heat recovery device 5 near the outdoor fresh air duct, and the outlet of the circulation pump 1 is connected to the bottom of the upper V-level solution heat recovery device 5 near the exhaust duct. The bottoms of each solution heat recovery device 5 are seq...

Embodiment 2

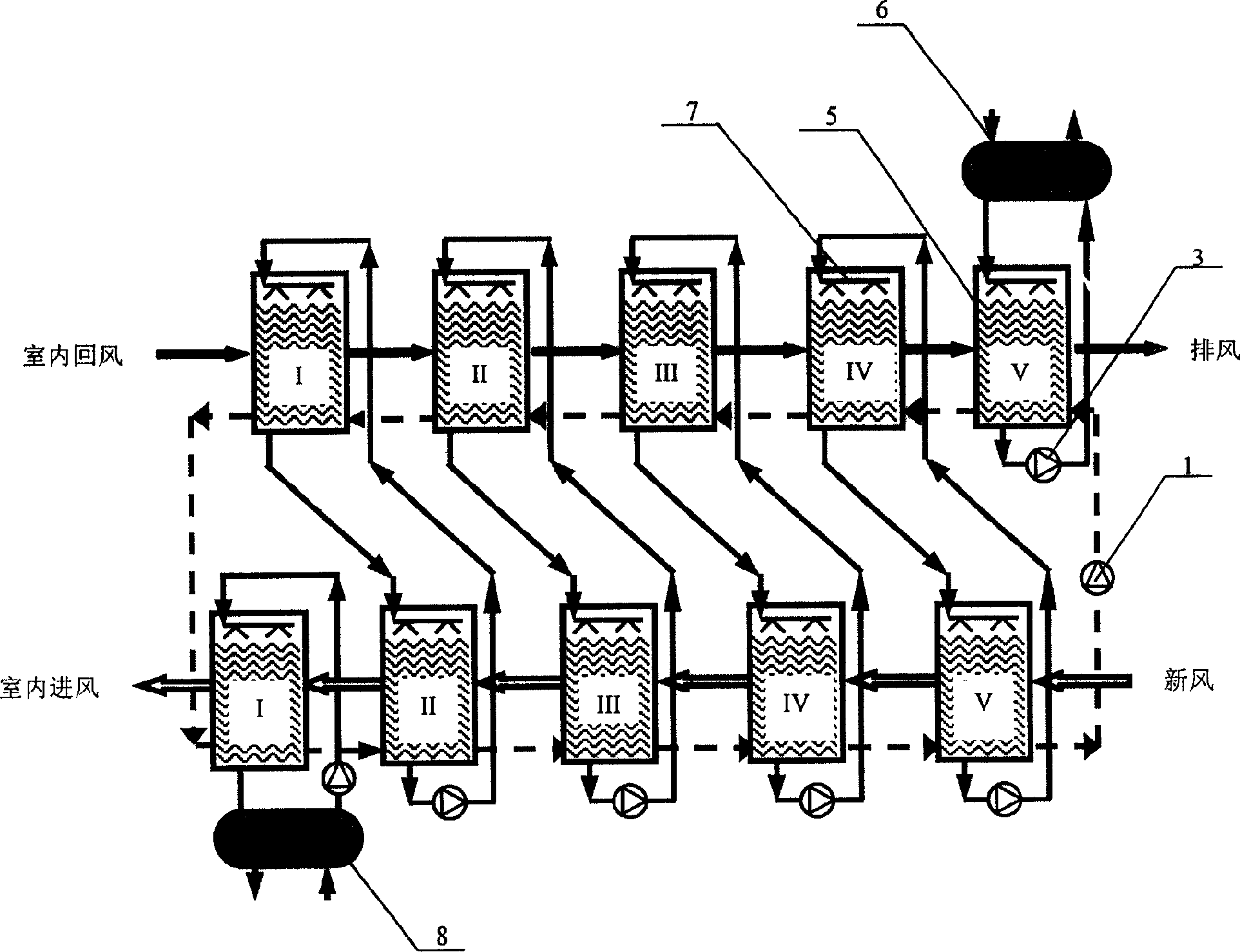

[0019] see figure 2 , the parts of this embodiment that are the same as those of the foregoing embodiment will not be described again. The difference is that the heat exchanger 2 in the above-mentioned embodiment is removed, and the bottom end of the solution heat recovery device 5 in the lower layer formed with a difference of one level between the upper and lower layers is all connected to the inlet of the single-stage spray pump 3 provided at this stage. , the outlets of each single-stage spray pump 3 are sequentially connected to the spray pipes 7 in the upper solution heat recoverers 5 that are one level apart from the upper and lower levels, and the bottoms of the upper solution heat recovery units 5 are sequentially one level apart from the upper and lower levels The spray pipes 7 in each solution heat recovery device 5 of the lower floor are connected. The use process of this embodiment is also the same as that of the above embodiment, except that the heat exchange l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com