Bentonite hybridization absorption material and its preparing process

A technology of water-absorbing materials and bentonite, which is applied in the field of bentonite hybrid water-absorbing materials and its preparation, can solve the problems of restricting popularization and application, high cost of high water-absorbing materials, etc., and achieve the effects of increasing crop yield, good compatibility, and abundant raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

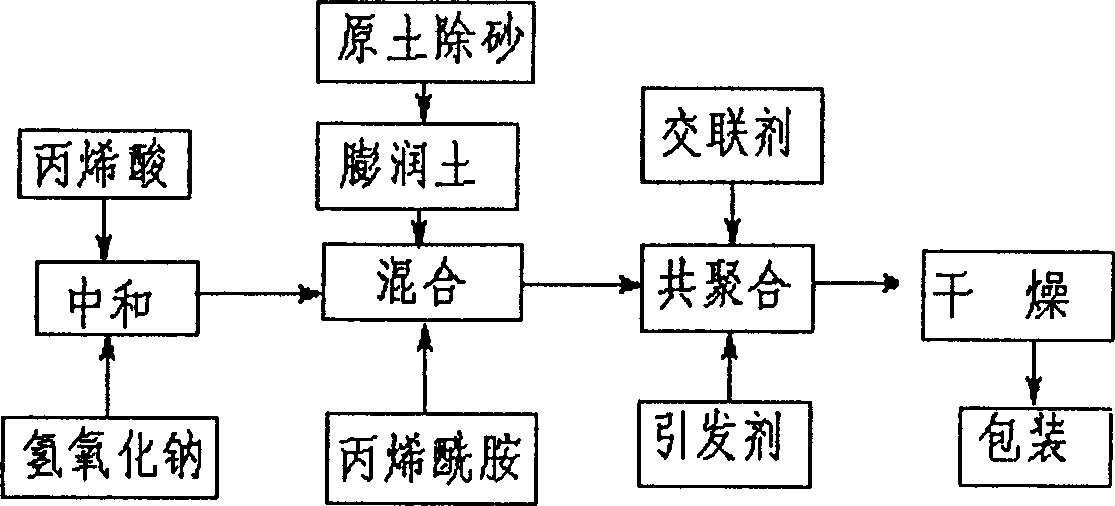

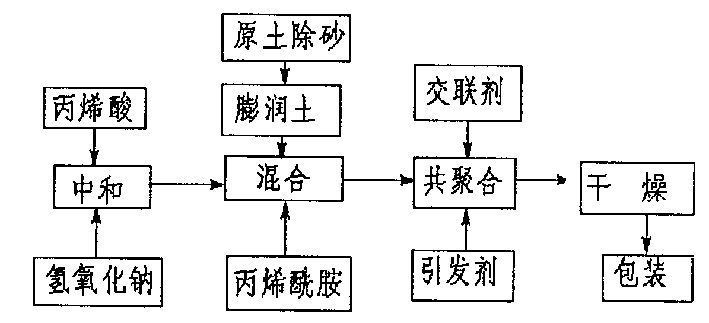

Method used

Image

Examples

Embodiment 1

[0017] Example 1, add 6 mol of acrylic acid neutralized with NaOH to make the neutralization degree reach 70% to a flask with a cold water bath and a stirring device, then add 4 mol of acrylamide and fully stir to dissolve it, then add 0.05% cross-linking agent and 30% bentonite, and finally add 1.5% over-initiator under full stirring, gradually raise the temperature to 80°C to initiate polymerization, dry and pulverize the obtained material for water absorption test and apply infrared and X-ray diffraction (model The prepared material was characterized by methods such as D / MAX-IIIC), and the hybrid structure of the material was further determined.

Embodiment 2

[0018] Example 2: Add 3 mol of acrylic acid neutralized with NaOH to a degree of neutralization of 80% into a flask filled with a cold water bath and a stirring device, then add 7 mol of acrylamide and fully stir to dissolve it, then add 0.05% cross-linking agent and 25% bentonite, and finally add 2.5% initiator under full stirring, gradually raise the temperature to 85°C to initiate polymerization, dry and pulverize the obtained material for water absorption test and apply infrared and X-ray diffraction (model is D / MAX-IIIC) and other methods were used to characterize the prepared materials to further determine the hybrid structure of the materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com