Dynamic circulating-stage continuous countercurrent extraction process

An extraction process and dynamic circulation technology, applied in the fields of pharmacy, chemical industry, and food processing, can solve the problems of affecting the extraction rate of active ingredients, increasing the content of non-active ingredients, contaminating the extraction liquid, etc., to shorten the time of migration to the surface, increase the The effect of extracting the driving force and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

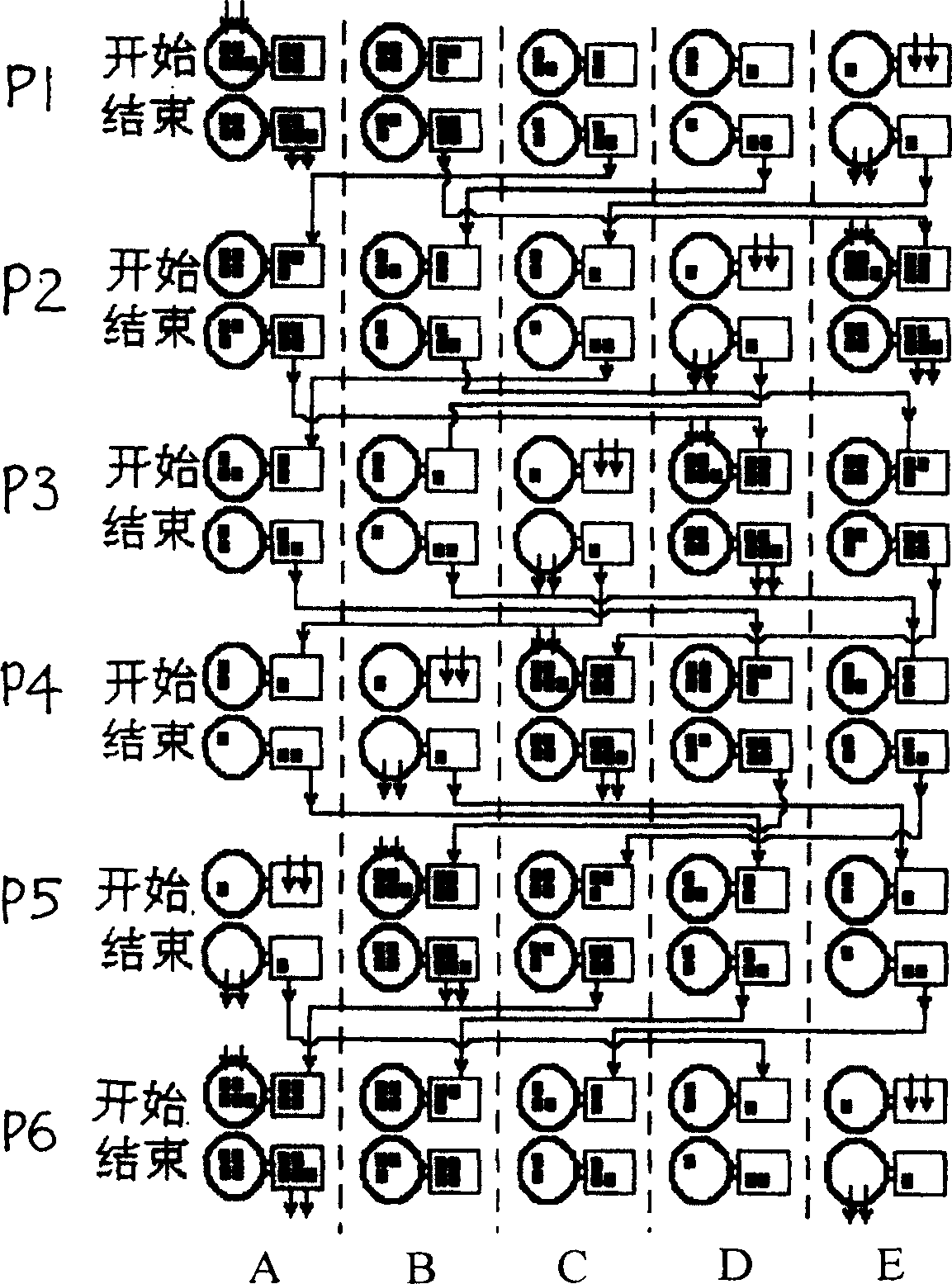

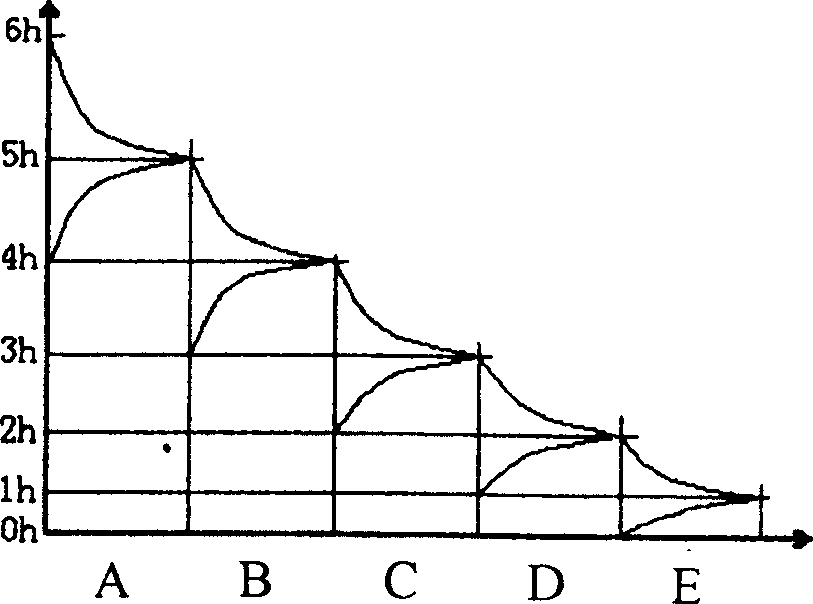

[0020] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

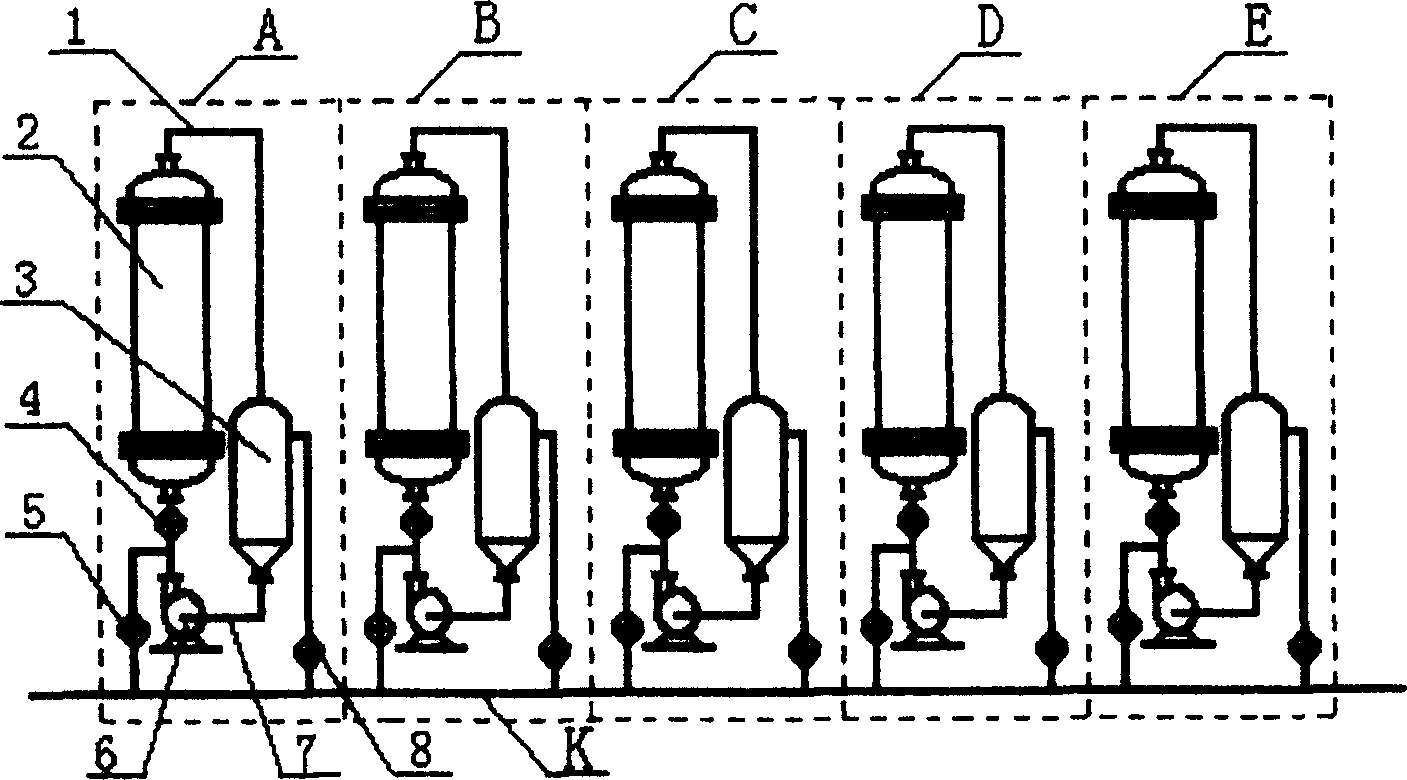

[0021] 1. Equipment composition.

[0022] The complete set of equipment consists of 5 identical dynamic circulation extraction units A, B, C, D, E, connected through the main pipe K, see figure 2 . Extraction unit A is composed of extraction tank 2, liquid storage tank 3, circulation pump 6, valves 4, 5, 8, pipelines 1, 7 and so on. The inlet of the circulating pump 6 is connected to the bottom of the liquid storage tank 3 through the liquid inlet pipe 7, the outlet of the circulating pump 6 is respectively connected to the lower head of the extraction tank 2 and the main pipe K through the valves 4 and 5, and the upper head of the extraction tank 2 The liquid storage tank 3 is connected to the liquid storage tank 3 through the pipeline 1, and the liquid storage tank 3 is connected to the main pipe K through the valve 8. The commercially availabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com