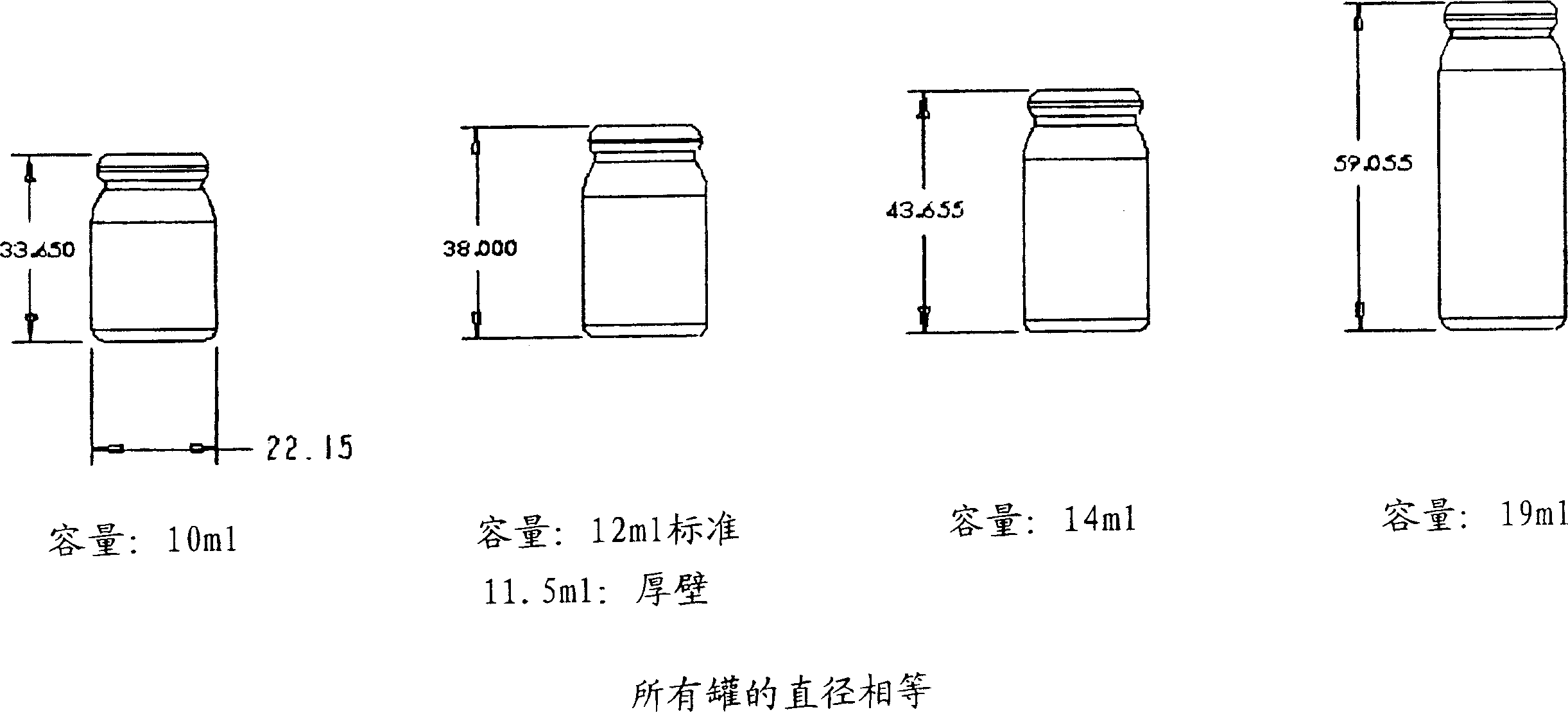

Method for applying polymer coating to internal surface of container

A kind of polymer coating and polymer technology, which is applied to the device, container, coating, etc. of the surface coating liquid, which can solve the problems of expensive application, drug pollution source, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

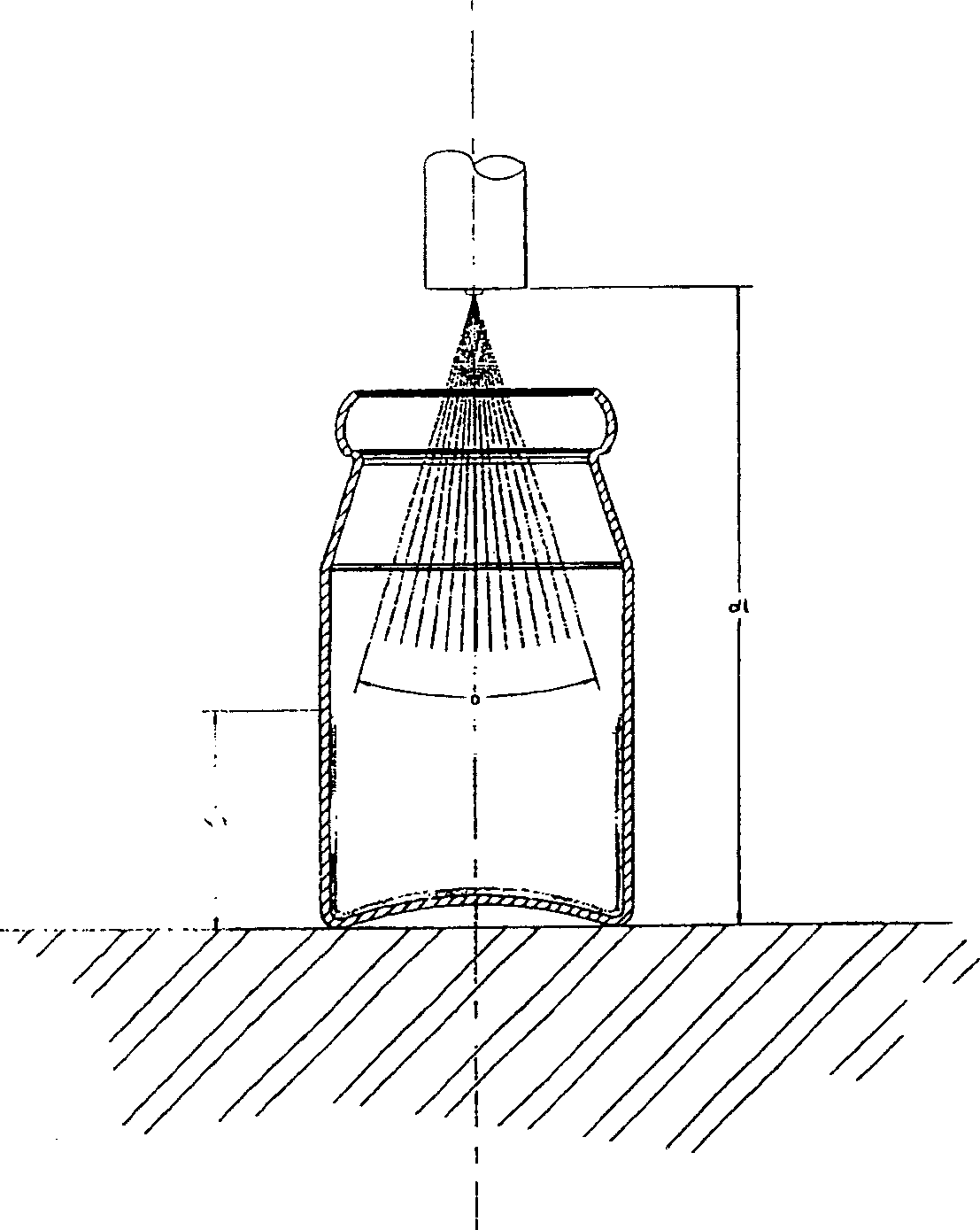

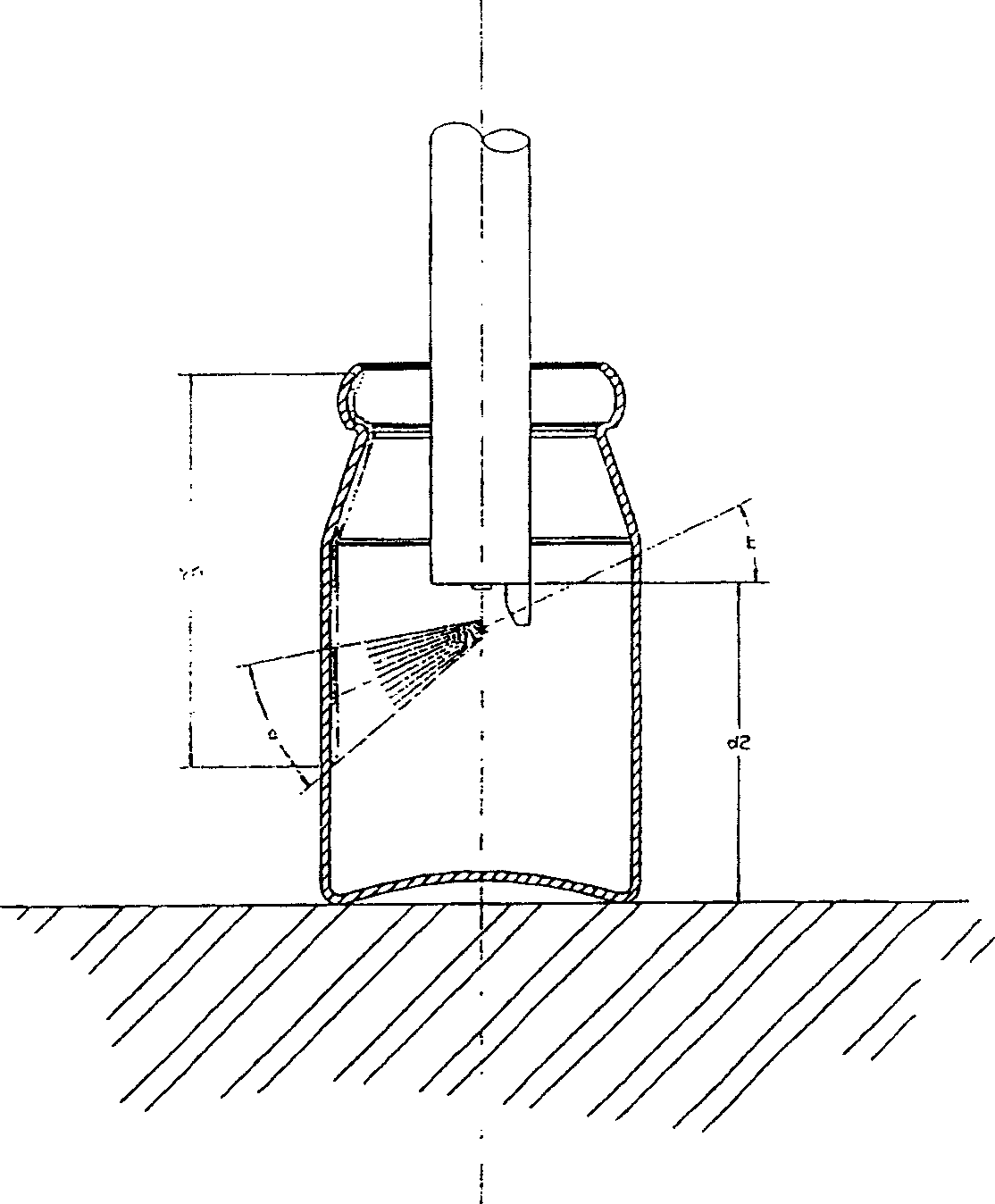

Method used

Image

Examples

Embodiment

[0092] Take eight standard non-anodized aluminum cans and ten anodized aluminum cans and coat substantially the entire interior surface of the cans. The standard cans were applied two polymer coats at a time using an in-line spray gun spray pattern. The anodized cans were applied with a single polymer coating using an axial spray gun spray pattern.

[0093] The surface topography was obtained using a Microfocus Compact Measurement system measurement. Measurements are made on the side wall of the tank. The coatings were sputtered with gold (VG Microtech Model SC7640 Sputter Coater) to improve surface reflectance prior to measurement. The measured area is 0.5 mm by 0.5 mm with a dot density of 100 dots / mm. Roughness coefficients for individual cans, as well as average, maximum and minimum roughness coefficients, for anodized and standard cans, are shown in Table 1.

[0094] Anodizing

tank number

Roughness (Ra)

standard

tank number

Roughn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com