Preparation method of supramolecular polymer films with humidity response and recyclability

A supramolecular polymer and film technology, applied in the chemical field, can solve the problems of multi-step preparation process and few polymer networks, and achieve wide application prospects, good humidity responsiveness and recyclability, improved and enriched functions The effect of sexual characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] With 10g lipoic acid (in formula I, n is 3, R 1 for hydrogen, R 2 Hydrogen) powder and 1.94g sodium hydroxide powder (the molar ratio of lipoic acid and sodium hydroxide is 1:1) was dissolved in a mixed solution of 110mL ethanol and water, the volume ratio of ethanol and water was 10:1, and heated to reflux for 1h , filtered and dried to obtain sodium lipoate powder.

[0047] 5g of sodium lipoic acid powder was dissolved in 5mL of water at a temperature of 70°C, and the yellow solution was coated on a glass substrate by spin coating and evaporated for 4 hours, and formed into a film in an air environment at a temperature of 25°C to obtain the described Supramolecular Polymer Films-1.

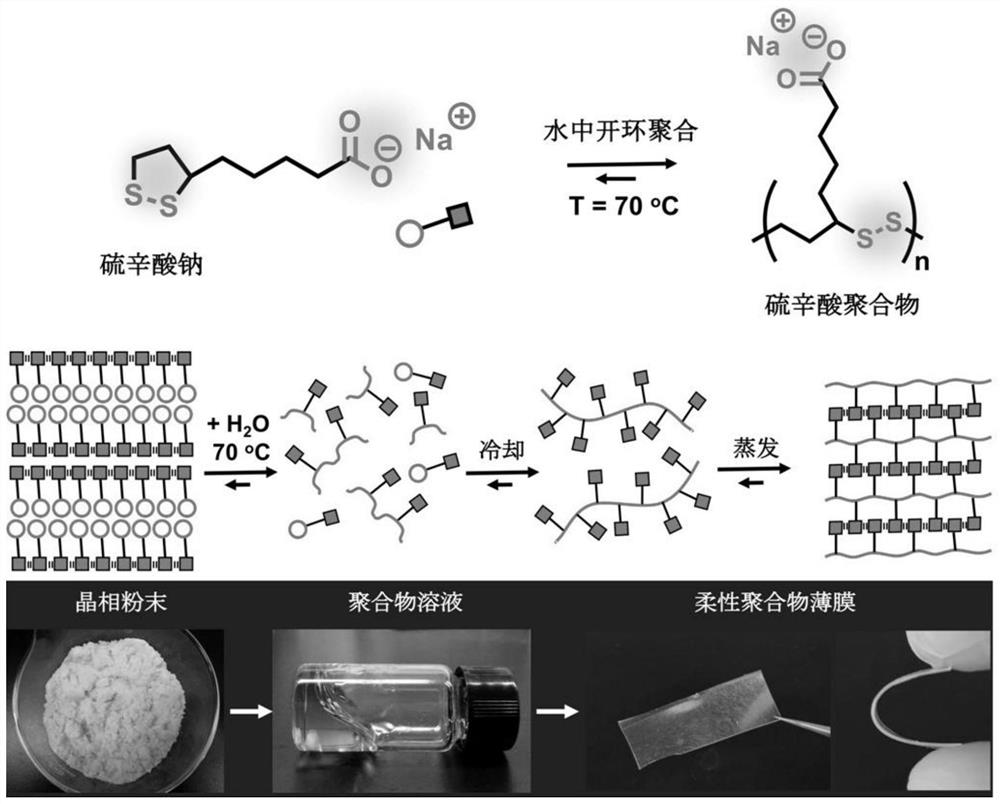

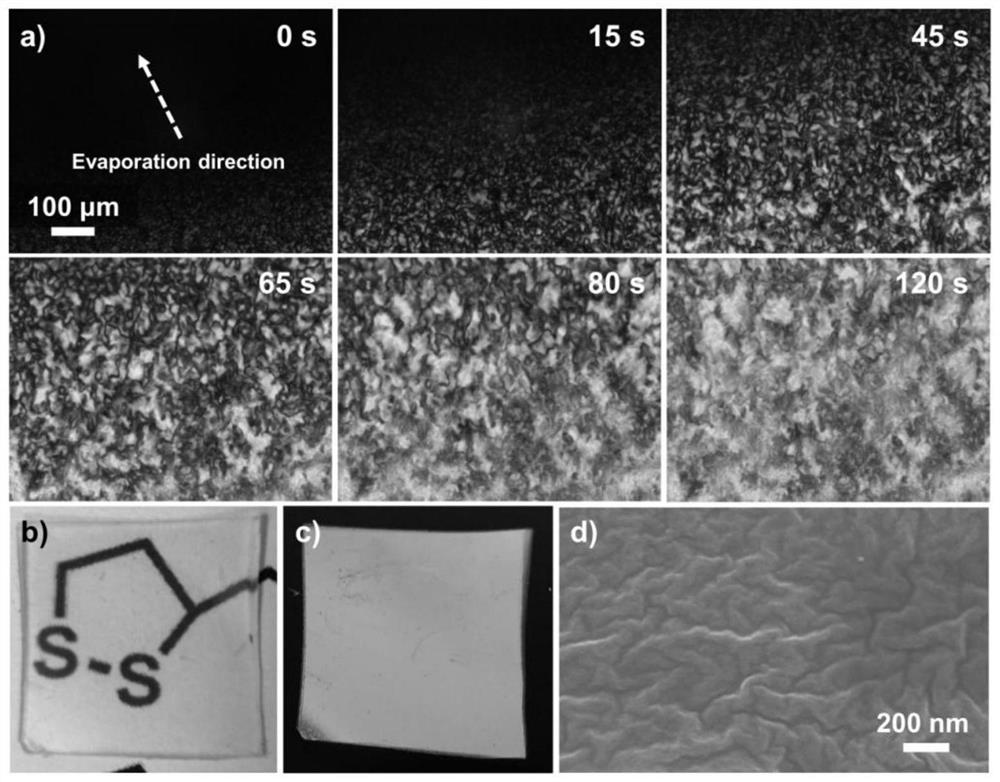

[0048] The molecular structure and outward appearance diagram of supramolecular polymer and supramolecular polymer film provided by the present invention are as follows: figure 1 as shown, figure 1 It is the molecular structure and appearance diagram of supramolecular polymer and supram...

Embodiment 2~24

[0054] Change the kind of alkali, raw material ratio (molar ratio of lipoic acid and alkali), alcohol-water mixed solution volume ratio, reflux time, film-forming temperature to obtain different supramolecular polymer films respectively, other are the same as embodiment 1, see table 1 for details .

[0055] Table 1

[0056]

Embodiment 25~33

[0058] Change the lipoic acid derivative type, the type of alkali, the raw material ratio (the molar ratio of lipoic acid and alkali), the volume ratio of the alcohol-water mixture, the reflux time, and the film-forming temperature to obtain different supramolecular polymer films respectively, and the others are the same as in the examples 1, see Table 2 for details.

[0059] Table 2

[0060]

[0061] Described lipoic acid derivative is shown in structural formula II:

[0062]

[0063] R 1 for hydrogen or C 1 ~C 4 Straight chain or branched chain alkyl, R 2 Is hydrogen or carboxyl (-COOH), n is an integer from 1 to 5, R 3 C containing carboxyl 1 ~C 15 Straight chain or branched alkylamino group, C containing carboxyl group 1 ~C 15 Straight chain or branched aryl, C containing carboxyl 1 ~C 15 Straight chain or branched chain alkyl.

[0064] The preparation method of the compound shown in the formula II comprises the following steps:

[0065] Mix lipoic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com