Wide-band-gap naphthalene organic semiconductor materials as well as preparation method and application thereof

An organic semiconductor and wide-bandgap technology, which is applied in the field of wide-bandgap naphthalene-based organic semiconductor materials and its preparation, can solve the problems of increased cost and instability of vacuum and light-shielding technologies, and achieve good thermal stability and light stability with low cost , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

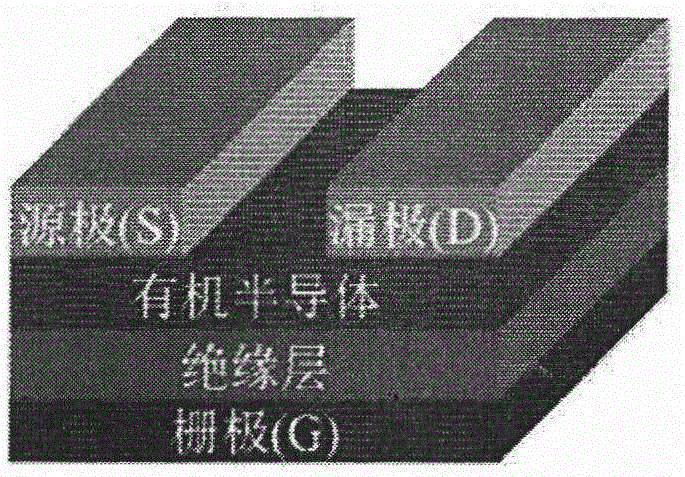

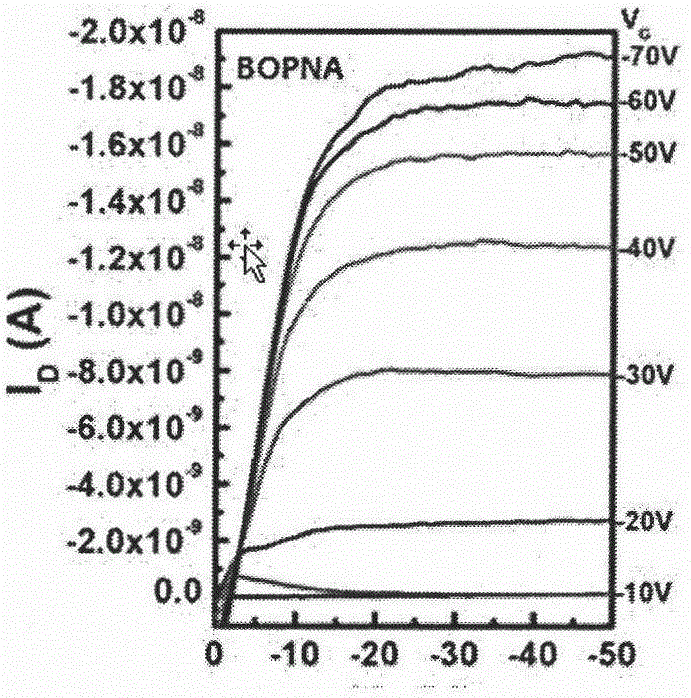

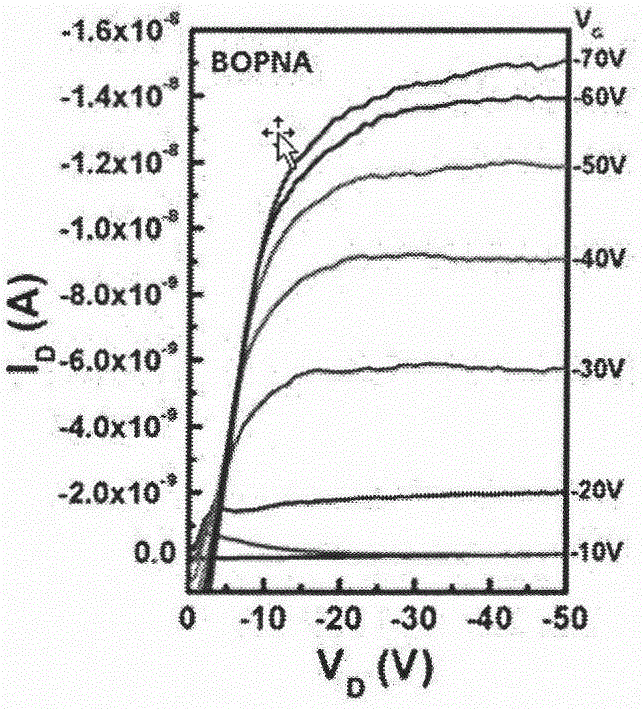

[0024] A wide bandgap naphthalene organic semiconductor material 2,6-bis(4-methoxybenzene)naphthalene (named BOPNA), its structural formula is:

[0025]

[0026] The preparation method of above-mentioned organic semiconductor material BOPNA comprises the steps:

[0027]

[0028] Into the reaction vessel, 2,6-dibromonaphthalene (5.76g, 20mmol), 4-methoxyphenylboronic acid (9.18g, 60mmol) and 150ml of toluene were successively added and mixed uniformly. Add saturated aqueous sodium carbonate solution (60ml) and tetrakistriphenylphosphopalladium (0.46g, 0.4mmol), pass nitrogen gas into the reaction solution for 20 minutes, heat the reaction solution to 105°C, reflux for 24 hours, turn off the heating, Stop responding. The obtained reaction solution was washed with methanol, dilute hydrochloric acid solution, and acetone successively, and 6.11 g (yield: 90%) of a white crude product was obtained after filtration. After the crude product was purified three times in a vacuum ...

Embodiment 2

[0030] A wide bandgap naphthalene organic semiconductor material 2,6-bis(4-methylthiophenyl)naphthalene (named BSPNA), its structural formula is:

[0031]

[0032] The preparation method of above-mentioned organic semiconductor material BSPNA, comprises the steps:

[0033] Into the reaction vessel, add 2,6-dibromonaphthalene (5.76g, 20mmol), 4-methylthiophenylboronic acid (10.08g, 60mmol) and 150ml of toluene in sequence, and mix well. Add saturated aqueous sodium carbonate solution (60ml) and tetrakistriphenylphosphopalladium (0.46g, 0.4mmol), pass nitrogen gas into the reaction solution for 20 minutes, heat the reaction solution to 105°C, reflux for 24 hours, turn off the heating, Stop responding. The obtained reaction solution was washed with methanol, dilute hydrochloric acid solution and acetone successively, and 6.53 g (yield 88%) of a white crude product was obtained after filtration. After the crude product was purified three times in a vacuum tube furnace, a light...

Embodiment 3

[0035] A wide bandgap naphthalene organic semiconductor material 2,6-bis(4-ethylbenzene)naphthalene (named BCPNA), its structural formula is:

[0036]

[0037] The preparation method of above-mentioned organic semiconductor material BCPNA, comprises the steps:

[0038] Into the reaction vessel, 2,6-dibromonaphthalene (5.76g, 20mmol), 4-ethylphenylboronic acid (9.00g, 60mmol) and 150ml of toluene were successively added and mixed uniformly. Add saturated aqueous sodium carbonate solution (60ml) and tetrakistriphenylphosphopalladium (0.46g, 0.4mmol), pass nitrogen gas into the reaction solution for 20 minutes, heat the reaction solution to 105°C, reflux for 24 hours, turn off the heating, Stop responding. The obtained reaction solution was washed with methanol, dilute hydrochloric acid solution, and acetone successively, and 6.18 g (92% yield) of a white crude product was obtained after filtration. The crude product was purified three times in a vacuum tube furnace to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com