Heat storage type gas radiation pipe burning machine

A radiant tube and burner technology, which is applied to combustion methods, combustion equipment, heat treatment furnaces, etc., can solve the problems of difficult replacement of igniters, high smoke exhaust temperature of radiant tubes, and low fuel utilization rate, etc., and achieves novel technical solutions. The effect of high combustion efficiency and long operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

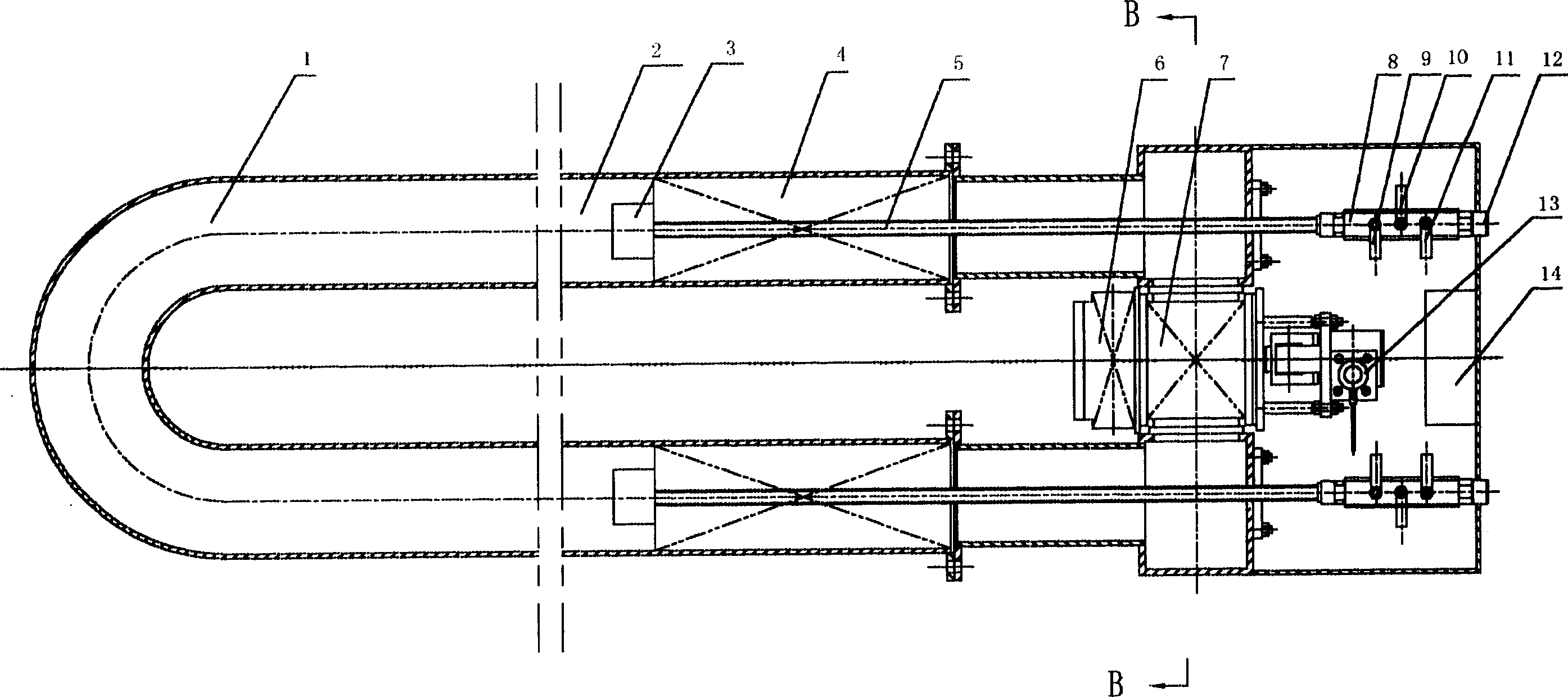

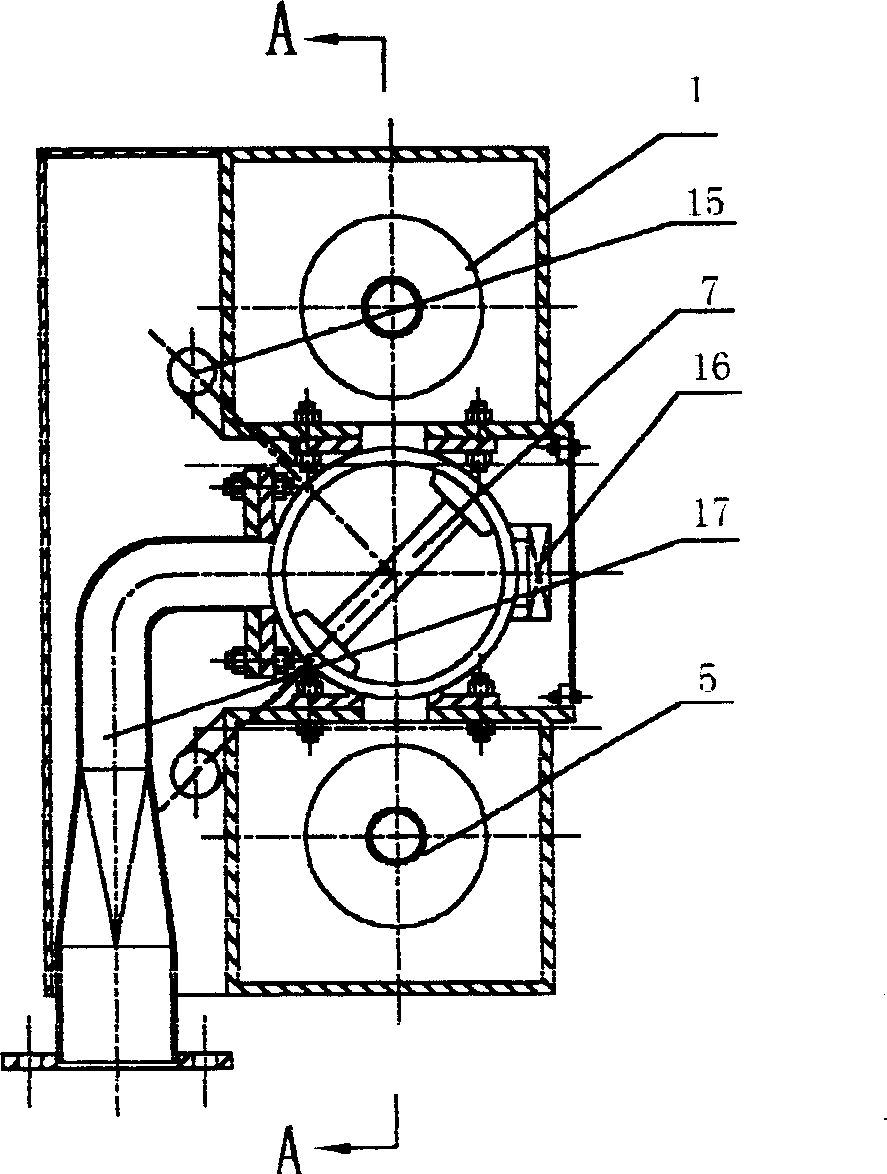

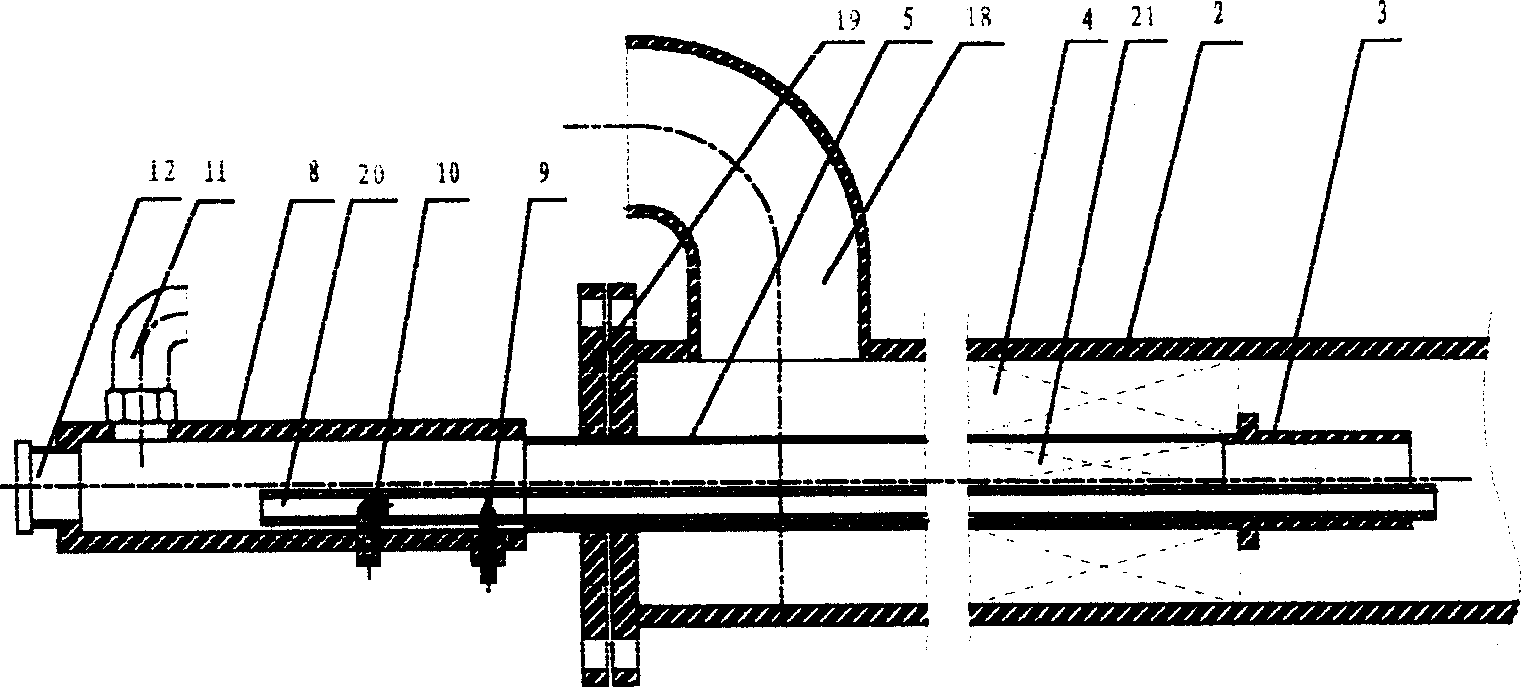

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. as attached figure 1 As shown, the main body of the burner is a U-shaped radiant tube, the U-shaped part of the front end is the combustion chamber, and the two rear end straight pipes are equipped with a secondary gas nozzle 3 and a regenerator 4, and the secondary gas nozzles 3 and The regenerators 4 work alternately, and when one end burns, the other end stores heat, so that the temperature field of the entire radiant tube is uniform and the thermal efficiency is high. A gas pipe 5 is arranged in the center of the straight pipe. The gas pipe 5 passes through the center of the storage body 4 and reaches the secondary gas nozzle 3. The rear end of the gas pipe is connected to the remote igniter 8, and the gas inlet 11 is connected to the control valve 6. The straight pipe The air / flue gas pipe at the rear end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com