Technical method for preparing crystal dry ice

A process method and dry ice technology, applied in chemical instruments and methods, refrigeration and liquefaction, inorganic chemistry, etc., can solve the problems of low productivity, large expansion volume, high maintenance costs, etc., and achieve crystal clear and transparent color, simple process method, and volatile long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

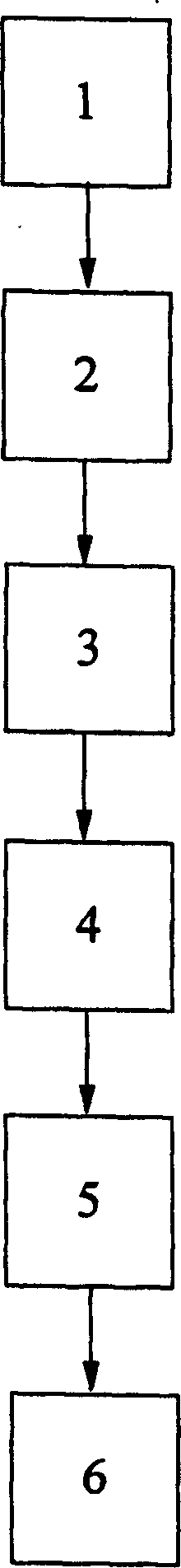

Image

Examples

Embodiment Construction

[0014] According to above process method concrete implementation is as follows:

[0015] 1. Inject an appropriate amount of carbon dioxide liquid into the container of the dry ice maker;

[0016] 2. Put it in the container of this refrigerator for pre-cooling, and place it in the environment with a temperature of -20°C for 20 minutes;

[0017] 3. The pre-cooled carbon dioxide is forced to refrigerate, the cooling temperature is -100°C, and the refrigerating time is 25 minutes. According to the amount of raw materials, the time is slightly changed;

[0018] 4. Crystal dry ice has been made in the container after cooling;

[0019] 5. The prepared crystal dry ice can be demolded after a little heating, and it is a kind of crystal dry ice with high density;

[0020] Put this dry ice into the beverage to form a cold mist on the surface of the beverage, increasing the coolness and taste of the beverage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com