Vertical flow composite type biological sludge minimization reactor and its operation method

A biological sludge and reactor technology, which is applied in biological sludge treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of unstable growth of protozoa and metazoa and ineffective sludge reduction, etc. Problems, to achieve easy automatic control, improve the effect of sludge reduction, and improve the effect of sludge settling and dewatering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

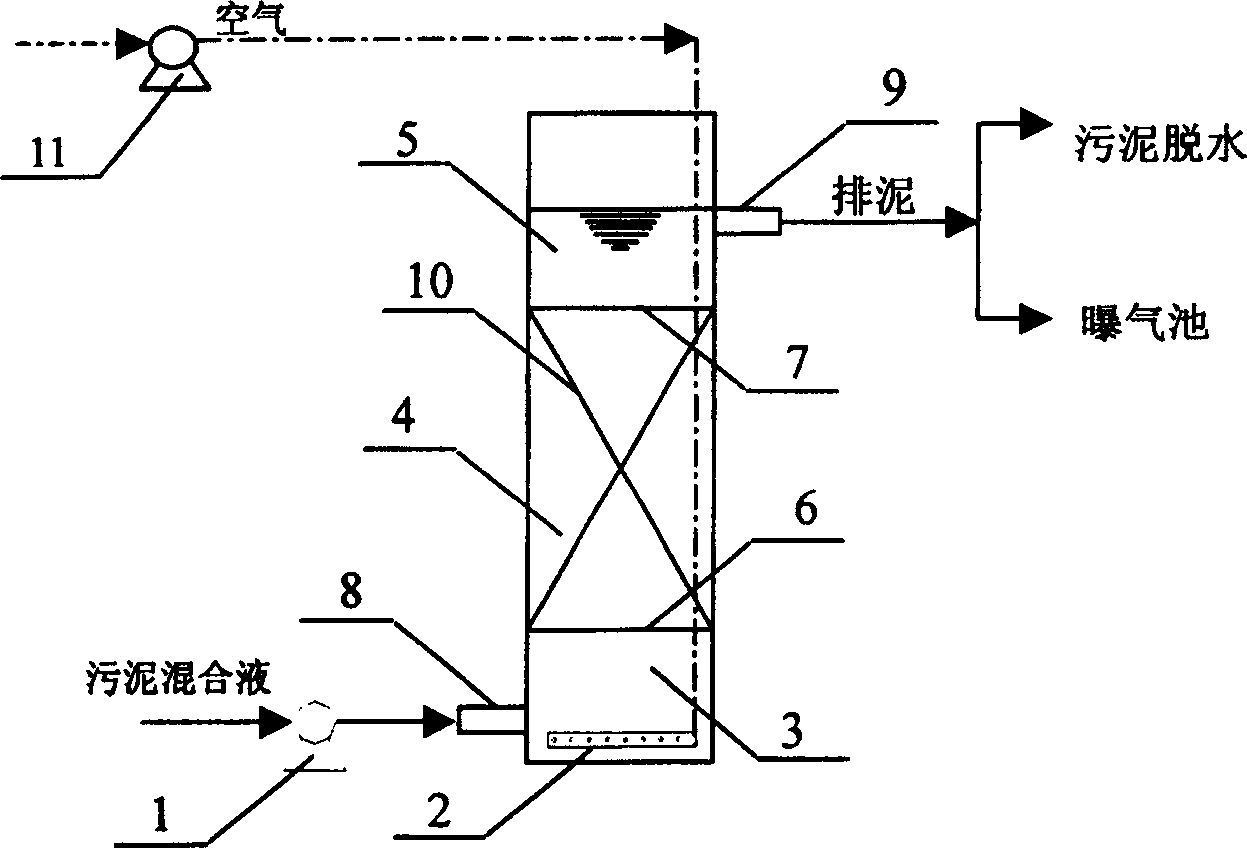

[0051] See figure 1 with 3 . A cylindrical vertical flow composite biological sludge reduction reactor, which is divided into free protozoa and metazoan growth areas by a perforated partition with a porosity of 5-10% and a pore diameter of 3-5mm. 3. Adherent protozoa And the metazoan growth zone 4 and the solid-liquid separation sedimentation zone 5 are used to reduce the amount of surplus sludge discharged from the sewage biological treatment system.

[0052] There is a sludge mixture inlet 8 at the lower part of the reactor side wall of the free-type protozoa and metazoan growth zone 3, and a sludge outlet 9 is provided at the upper part of the reactor side wall of the solid-liquid separation sedimentation zone 5. The sludge mixture inlet 8 is connected with the sludge transfer pump 1.

[0053] An aerator 2 connected with an air compressor or a blower 11 is installed in the free-type protozoan and metazoan growth zone 3, and the entire reactor is aerated through the aerator 2. ...

Embodiment 2

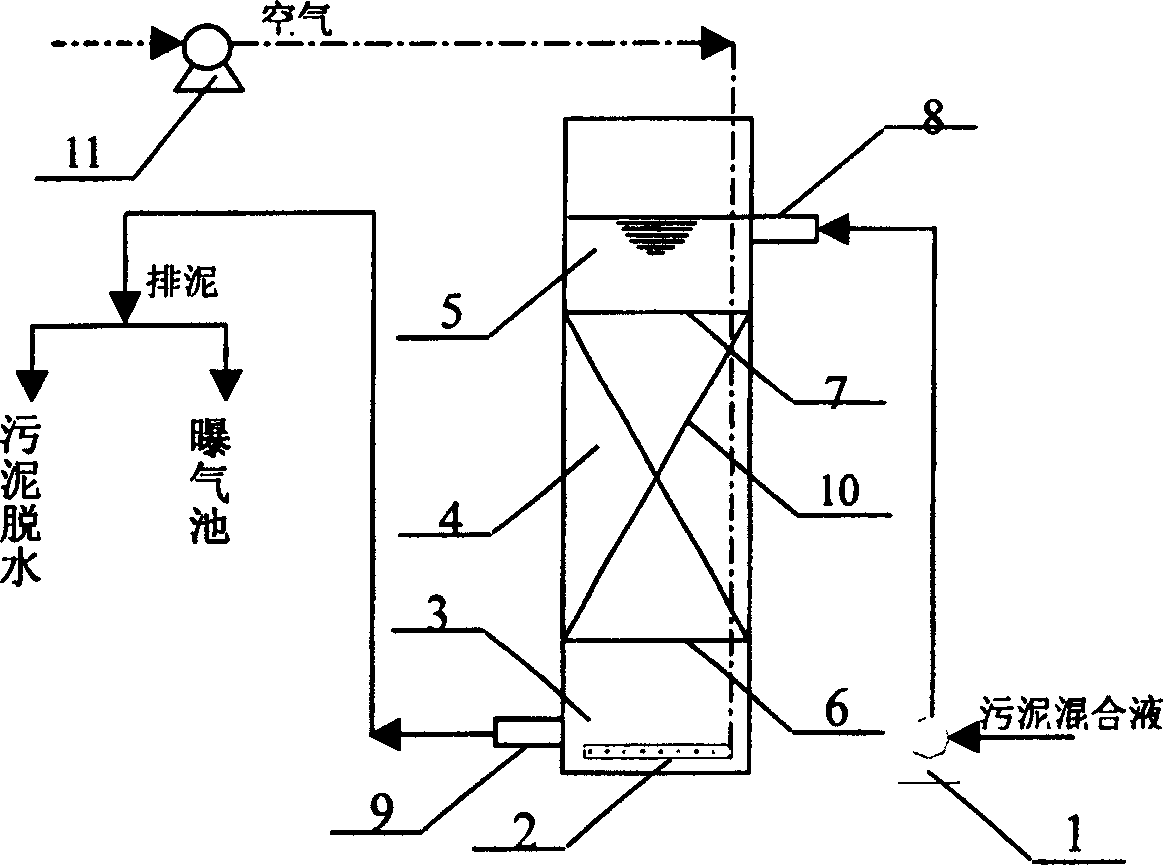

[0058] See figure 2 with 4 . A cylindrical vertical flow composite biological sludge reduction reactor is divided into free protozoa and metazoan growth zone 3 by perforated partitions with a porosity of 5-10% and a pore diameter of 3-5mm. 3, attached protozoa The metazoan growth area 4 and the solid-liquid separation sedimentation area 5 are used to treat the return sludge of the conventional activated sludge method, and are integrated with the aeration tank and the secondary settling tank to reduce the amount of sludge produced.

[0059] There is a sludge discharge port 9 at the lower part of the reactor side wall of the free-type protozoan and metazoan growth zone 3, and a sludge mixed liquid inlet 8 is provided at the upper part of the reactor side wall of the solid-liquid separation sedimentation zone 5. The sludge mixture inlet 8 is connected to the sludge transfer pump 1; the height of the outlet of the sludge outlet 9 is equal to the height of the sludge mixture inlet 8 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com