Method for purification and recovery of methane from refuse landfill gas

A landfill gas and landfill gas technology, applied in organic chemistry, adsorption purification/separation, waste fuel, etc., can solve the problem of difficult removal of trace impurities, achieve considerable social and economic benefits, be conducive to environmental protection, and broad The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

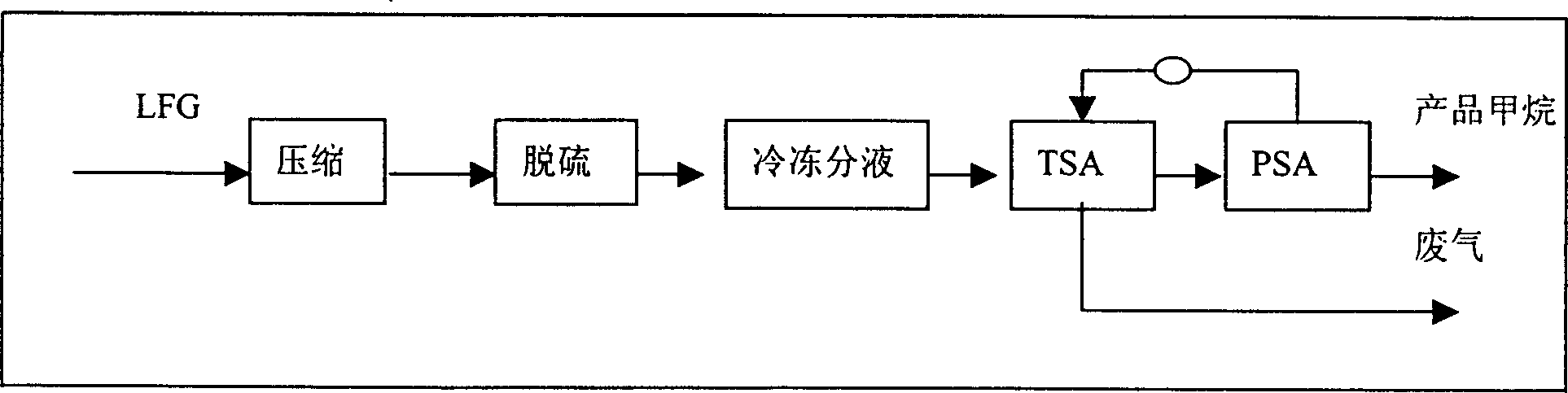

[0023] The invention is composed of technical processes such as compression, desulfurization, freezing liquid separation, temperature swing adsorption and pressure swing adsorption (both are two beds). Its process is shown as figure 1 :

[0024] The specific content of the present invention is described as follows.

[0025] Compression: Landfill gas at atmospheric pressure is compressed to the pressure required by the subsequent process in order to overcome sufficient resistance drop and meet the C0 of PSA 2 Removal rate and CH 4 Requirements for recovery rate, compressed landfill gas pressure is 0.2MPa(G) or 1.5MPa(G) or 2.5MPa(G).

[0026] Desulfurization: The desulfurization process uses modified activated carbon and iron oxide composite desulfurizer, and the ratio is 1:1~10 (volume ratio). The landfill gas with a pressure of 0.2MPa(G) or 1.8MPa(G) or 2.5MPa(G) is sent to the desulfurization process for desulfurization, so that the sulfur content in it is ≤20mg / m 3 , t...

Embodiment 2

[0045] This example adopts a 2-bed system of temperature swing adsorption process and a 4-bed secondary pressure equalization system of pressure swing adsorption process. The TSA adsorption bed is filled with alumina and silica gel with a volume ratio of 1:6, and the PSA adsorption bed is filled with alumina and silica gel with a volume ratio of 1:7.

[0046] The landfill gas composed as shown in Table 1 is compressed to 0.5MPa by the compressor, and enters the desulfurization system for desulfurization. The desulfurization system adopts a two-tower series-parallel process, and the desulfurizer uses modified activated carbon and iron oxide composite desulfurizer, and the ratio is 1. : 2 (volume ratio), remove sulfur from landfill gas to ≤20mg / m 3 Then it enters the freezing liquid separation system. The operating temperature of the freezing liquid separation system is 5°C, and most of the water and high boiling point impurities in the landfill gas are separated. The prelimina...

Embodiment 3

[0050] This example adopts a 2-bed system of temperature swing adsorption process and a 6-bed three-time pressure equalization system of pressure swing adsorption process. TSA is attached with tower to install alumina and activated carbon, the volume ratio is 1:2, PSA is attached with tower to install alumina and silica gel, and the volume ratio is 1:9.

[0051] The landfill gas with the composition shown in Table 1 is compressed to 0.7MPa(G) by the compressor, and then enters the refrigerated liquid separation system. The operating temperature of the refrigerated liquid separation system is 6°C, and most of the water and high-boiling point impurities are condensed and separated out of the garbage. Landfill gas and landfill gas enter the desulfurization system for desulfurization. The desulfurizer uses modified activated carbon and iron oxide composite desulfurizer. The ratio is 1:5 (volume ratio), and the sulfur is desulfurized to ≤20mg / m 3 The preliminarily purified landfill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com